3

A - GENERAL INFORMATION

TO THE PURCHASER

Congratulations! You are the owner of one of the

fi

nest

pumps on the market today. These pumps are products

engineered and manufactured of high quality components.

With years of pump building experience along with a con-

tinuing quality assurance program combine to produce a

pump which will stand up to the toughest applications.

Check local codes and requirements before installation.

Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

RECEIVING

Upon receiving the pump, it should be inspected for dam-

age or shortages. If damage has occurred,

fi

le a claim

immediately with the company that delivered the pump.

If the manual is removed from the crating, do not lose or

misplace.

STORAGE

Short Term -

Pumps are manufactured for ef

fi

cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as

factory assembled, in a dry atmosphere with constant

temperatures for up to six (6) months.

Long Term -

Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained b40 deg. F and

+120 deg. F. Pump should be stored in its original shipping

container and before initial start up, rotate impeller by hand

to assure seal and impeller rotate freely.

SERVICE CENTERS

For the location of the nearest Weinman Service Center,

check your Weinman representative or Crane Pumps &

Systems, Inc., Service Department in Piqua, Ohio, telephone

(937) 778-8947 or Crane Pumps & Systems Canada, Inc.,

Bramton, Ontario, (905) 457-6223.

B- INSTALLATION

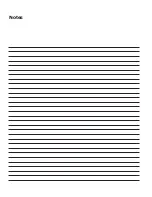

1. FOUNDATION

The pump foundation should be suf

fi

ciently substantial

to form a level, rigid support for the combined weight

of the pump and driver and maintain alignment of the

installed unit. Foundation bolts, of the proper size, should

be imbedded in the concrete. A pipe sleeve, about 2½”

diameters larger than the bolt, should be used to allow for

fi

nal positioning of the bolts. See Figure 1.

2. MOUNTING - Type VB and VBM:

Position the unit on the foundaton and level the pump

base, using metal shims, so that the pump shaft is in

vertical alignment and the pump suction and discharge

fl

anges are level in both vertical and horizontal plane. Base

may be grouted following alignment. Use a plumb line from

fl

oor above to establish centerline of pump and

fl

exible

drive shaft and bearings.

Type B Units:

Pumps and drivers that are received from the factory

with both machines mounted on a common baseplate,

were accurately aligned before shipment. All baseplates

are

fl

exible to some extent and, therefore, must not be

relied upon to maintain the factory alignment. Preliminary

alignment is necessary after the complete unit has been

leveled on the foundation, and again, after the unit is

piped, and rechecked periodically as outlined in the

following paragraphs.

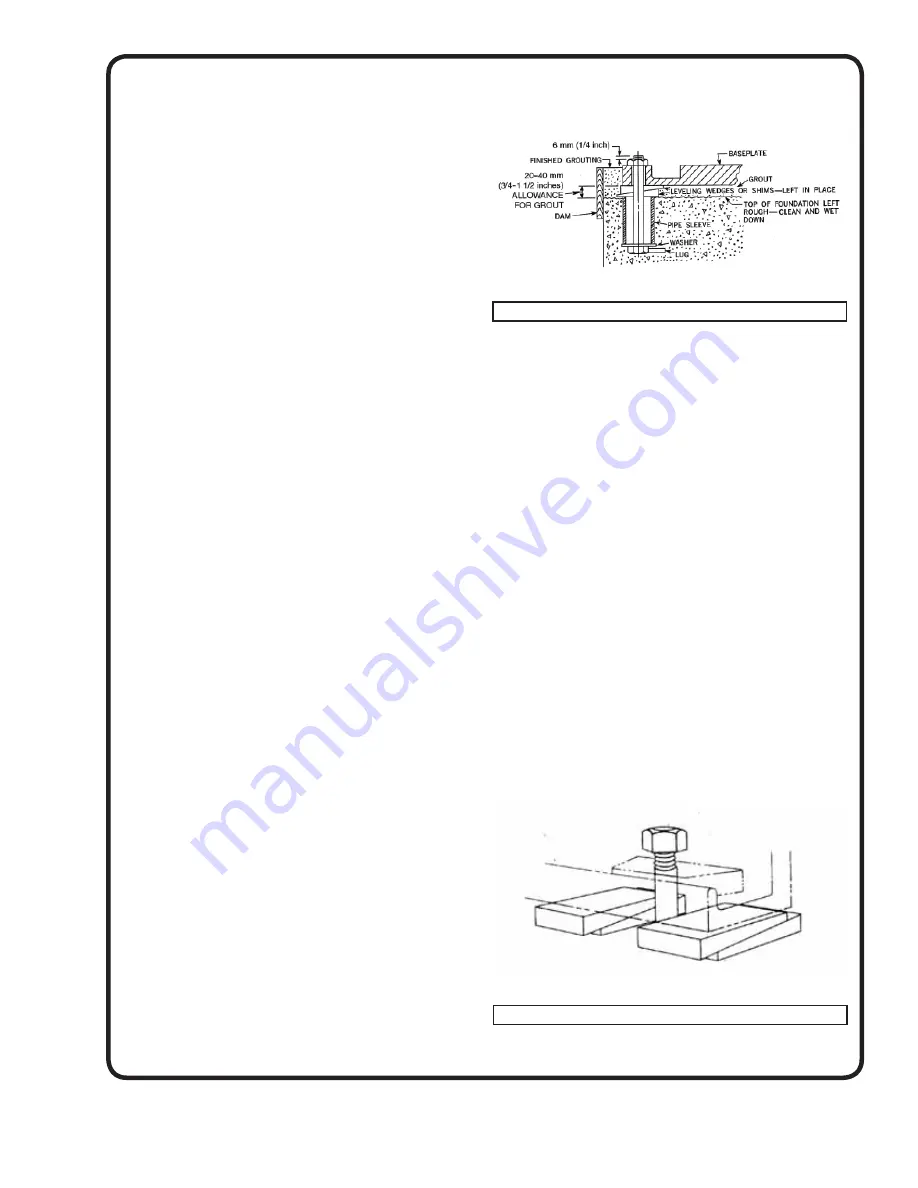

Position unit on foundation and level the baseplate,

using rectangular metal blocks and shims, or wedges

having a small taper as shown in Figure 2. A gap of 3/4”

to 1½” should be allowed between the baseplate and

foundation for grouting.

Figure 1. Foundation Bolt Location and Anchorage

Figure 2. Adjusting Wedges for Mounting

Summary of Contents for Weinman B Series

Page 16: ...Notes ...