6

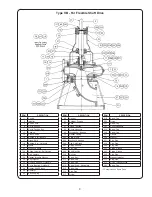

D. MAINTENANCE

1. LUBRICATION

The pump and its component parts that require lubrication

have been lubricated at the factory, except for bearings

that are oil lubricated. Oil reservoir must be

fi

lled before

start up. (See below)

Subsequent lubrication depends on operating conditions.

Periodic inspection of bearing lubrication is necessary and

additional grease or oil should be added as required.

CAUTION: DO NOT overgrease bearings or add

excess oil.

The following lubricants are recommended:

Grease lubricated ball bearings: Shell Alvania #71012 or

equal.

Oil lubricated ball bearings: SAE #10 non-detergent type

oil.

Packing boxes: Lithium base grease. Shell Alvania

#71012 or equal.

Double seal: Pressurized water or light oil circulated

through seal chamber. See below for recommended

lubrication.

Driver: See Manufacturers recommendations for proper

lubrication.

NOTE:

Under normal conditions, a ball bearing will run

10

0

F to 60

0

F above surrounding temperatures. If bearing

temperature becomes extremely hot, check for improper

lubrication, such as over-greasing, wear, incorrect pump

alignment, etc.

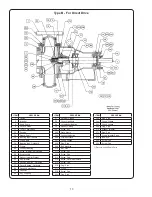

SERIES B ONLY:

To

fi

ll the oil reservoir in the frame (19)

1. Install the TRICO OPTO-MATIC CONSTANT LEVEL

OILER (77) on the frame. Unscrew the plastic bottle

from the oiler and remove breather (235) from the

frame.

2. Fill the bottle of the oiler and screw it onto the lower

reservoir.

Several

fi

llings of the bottle will be required

before the oil level in the bearing reservoir is equal

to the level for which the oiler is adjusted.

NEVER

fi

ll

the frame reservoir through the lower reservoir of the

oiler or re

fi

ll bottle while pump is operating.

3. When proper oil level is obtained, re

fi

ll and replace the

plastic bottle on the oiler and replace the breather

(235) in the frame.

DOUBLE SEAL LUBRICATION

The seal chamber of the packing box cover (11) must be

pressurized with a clear liquid to cool and lubricate the

seal faces. Liquid should be circulated through the seal

chamber at a pressure equal to or 15 to 20 psi above

maximum pressure at the pump discharge.

Recommended lubrication systems are as follows:

1. Water from an outside source, such as a water seal

system or light oil from a pressurized system.

2. Liquid from the pump casing (1) through a suitable

fi

lter if liquid is not over 180°F. Heat exchanger is

required for higher liquid temperatures.

3. Pumps with seal chamber may be pressurized with

Shell Alvania EPRO #71030 grease through suitable

grease

fi

tting if liquid lubrication is not available.

2. IMPELLER ADJUSTMENT

An outstanding feature of this pump is the axial

adjustment of the impeller to compensate for eventual

wear or corrosion. Correct impeller adjustment will insure

optimum operating performance and ef

fi

ciencies.

To adjust impeller clearance:

a. Disconnect power supply to the driver at the starter.

b. Loosen the three lock nuts and jack screws (204

and 286), then tighten the three cap screws (213)

evenly until the impeller just rubs the suction cover

(9) when the shaft is rotated by hand. It may be

necessary to bump the shaft lightly on the coupling

end to make sure impeller is against the suction cover.

c. Tighten the jack screws (286),

fi

nger tight, against

the power frame (19); then loosen cap screws (213).

d. Tighten the jack screws an additional 1/3 turn

(2 hex) to obtain .016” to .020” impeller clearance.

The clearance may be measured with feeler

gauge through suction inlet of the suction cover.

e. Carefully tighten cap screws (213) and lock nuts

(204), then rotate shaft by hand to make certain that

impeller does not rub against suction cover. Place

pump in operation and check power draw to make

certain impeller does not rub casing.

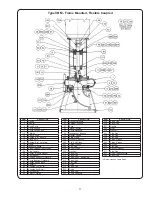

3. PACKING BOX CARE

Pumps are normally furnished with grease

fi

ttings (243) for

packing lubrication, unless purchased otherwise.

When installing new rings of packing, clean packing box

(11) and inspect parts for any damage. If the shaft sleeve

(14) is worn or grooved, it should be replaced. New packing

will not provide adequate sealing on a worn shaft sleeve.

Insert two new rings of packing in front of lantern ring.

Stagger joints to minimize leakage. Tamp each ring in

place. Rotate shaft several times after tamping each ring.

Replace lantern ring. Add three rings of packing behind

lantern ring. Replace gland (17) and bolts (209) and nuts

(210), rotate shaft and tighten gland securely. Be sure

lantern ring is positioned to receive lubrication through item

(243). After rotating shaft several turns, loosen nuts (210) to

fi

nger

fi

ght for starting.

IMPORTANT:

The liquid being pumped should slowly

and constantly drip through the packing and gland. This

prevents overheating, high power consumption and sleeve

damage. Lubricate through grease

fi

tting (243) or by

removal of

fi

tting and substituting tubing and an outside

source of water or oil.

Summary of Contents for Weinman B Series

Page 16: ...Notes ...