7

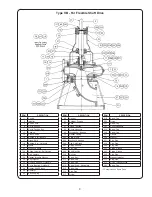

4. DISASSEMBLY

The disassembly instructions apply to the series of pumps

in general and may vary slightly on special units. If complete

disassembly is not necessary, use only those steps which

apply. Close gate valve in discharge and suction piping.

Inspect all parts removed to determine whether suitable for

reuse. It is recommended that all packing, gaskets and

O-rings be replaced with new ones during reassembly.

NOTE: Special precautions must be observed when

handling mechanical seals, so as not to damage the

lapped faces of the seals.

Unless casing (1) or suction cover (9) is damaged, or it is

necessary to replace suction cover wear ring (25), it may

not be necessary to remove the suction and discharge

piping to service the power end.

a. Remove drain plug (216) from casing or (231)

from suction elbow.

b. Remove all cooling or lubrication lines.

c. Disconnect power supply to motor and remove

motor; coupling spacer or

fl

exible drive shaft, so

that power frame assembly may be removed

from the casing (1).

d. Remove casing cap screws (212) and packing

box cover cap screws (334), where used and

separate power end from casing (1).

e. Remove impeller screw (26) by turning counter

clockwise, washer (210), impeller screw gasket

(28) and pull impeller (2) from the shaft with an

impeller or wheel puller. Remove impeller key

from the shaft, also shaft sleeve gasket (38).

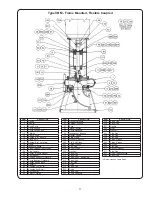

PACKING BOX COVER (11)

a. With Packing (13): Remove gland nuts (210),

or cap screws (282), gland clips (206) and gland

(11). Packing box cover may be removed from

frame (19). Remove packing (13) and lantern

ring (29) from packing box cover and clean the

bore of the cover.

b. With Mechanical Seal (89): Remove gland nuts

(210) and carefully remove packing box cover

from frame (19). Inboard stationary seal seat

can be pushed from the cover and outboard

stationary seal seat can be removed from seal

gland. Before removing seal rotating assembly,

depending on type of seal furnished, scribe a

mark on sleeve to show location of spring

retainer, then seal rotating assembly may be

removed, being careful so as no to damage

sealing faces, O-ring, etc.

SHAFT SLEEVE (14)

The shaft sleeve is mounted on the pump shaft (6) by

means of heat shrink

fi

t. To remove shaft sleeve, dismantle

power frame as below, place shaft in a vise and proceed as

follows:

1. With a hand grinder and a thin grinding wheel

(approx. 1/8” wide), cut a groove axially along the

sleeve to the shoulder of the shaft. Grind the

groove as deep as possible without damaging

the

shaft.

2. After the groove has been cut, insert a wedge

tipped cold chisel into the groove at the impeller

end of the sleeve. Support shaft on a V block

under the sleeve. Tap chisel sharply with a hammer

until crack occurs along the base of the groove.

3. Pry groove apart and remove sleeve from shaft.

FRAME (19)

a. Remove pump half of

fl

exible coupling and key

(46) from pump shaft (6). Remove cap screws

(213), cap screws (332) and jack screws (286)

with adjusting lock nut (204) and pull bearing

cover (37) and seal (49) from bearing housing (33).

b. Open tangs of lockwasher (69) and unscrew and

remove bearing locknut (22) and bearing

lockwasher

(69).

c. Insert a small pry bar at several points under the

fl

ange of the bearing housing (33) and carefully

force the shaft (6) with bearing housing (33)

bearings (18 and 16) and grease retainer (51)

from the coupling end of the frame (19).

d. Mark position of grease retainer on the shaft,

then remove grease retainer and bearing (16)

from impeller end of shaft.

NOTE:

To remove inner race roller bearing (16), carefully

apply heat to the inner race until it can be pulled from

shaft.

e. With bearing puller, remove bearing housing (33)

and bearing (18) from coupling end of shaft.

Press bearing from the bearing housing.

f. Wash bearings, bearing housing and bearing

covers to remove old grease, also

fl

ush old

grease from frame (19). Press seals (41 and 49)

from bearing covers (35 and 31) ad inspect for

wear.

WEARING RINGS (8 and 25)

a. To replace suction cover ring (25), remove cap

screw (215) and suction cover (9) from casing (1).

Remove machine screws (343) and then remove

ring (25). Clean ring seat before installing new ring.

b. To replace impeller ring (8), (remove set screws

(296) when used), place a wedge-tipped or

pointed cold chisel against the side of the ring

and tap chisel sharply with a hammer, forcing the

ring from the impeller (2).

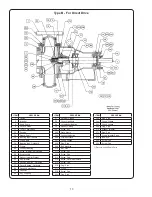

5. REASSEMBLY

FRAME (19)

a. Position grease retainer (51) onto the shaft (6) to

position previously-marked and tighten set

screws. Press inboard ball bearing (16) onto the

shaft until inner race is against shaft shoulder.

Apply fresh grease to the bearing (don’t over

grease),

fi

ll chamber 1/3 full.

b. Carefully press outboard ball bearing (19) into the

bearing housing (33) until seated in the bottom

of the housing. Press bearing housing assembly

onto the shaft (6) until bearing inner race is

against shaft shoulder. Apply fresh grease to the

being and the housing.

Summary of Contents for Weinman B Series

Page 16: ...Notes ...