¯

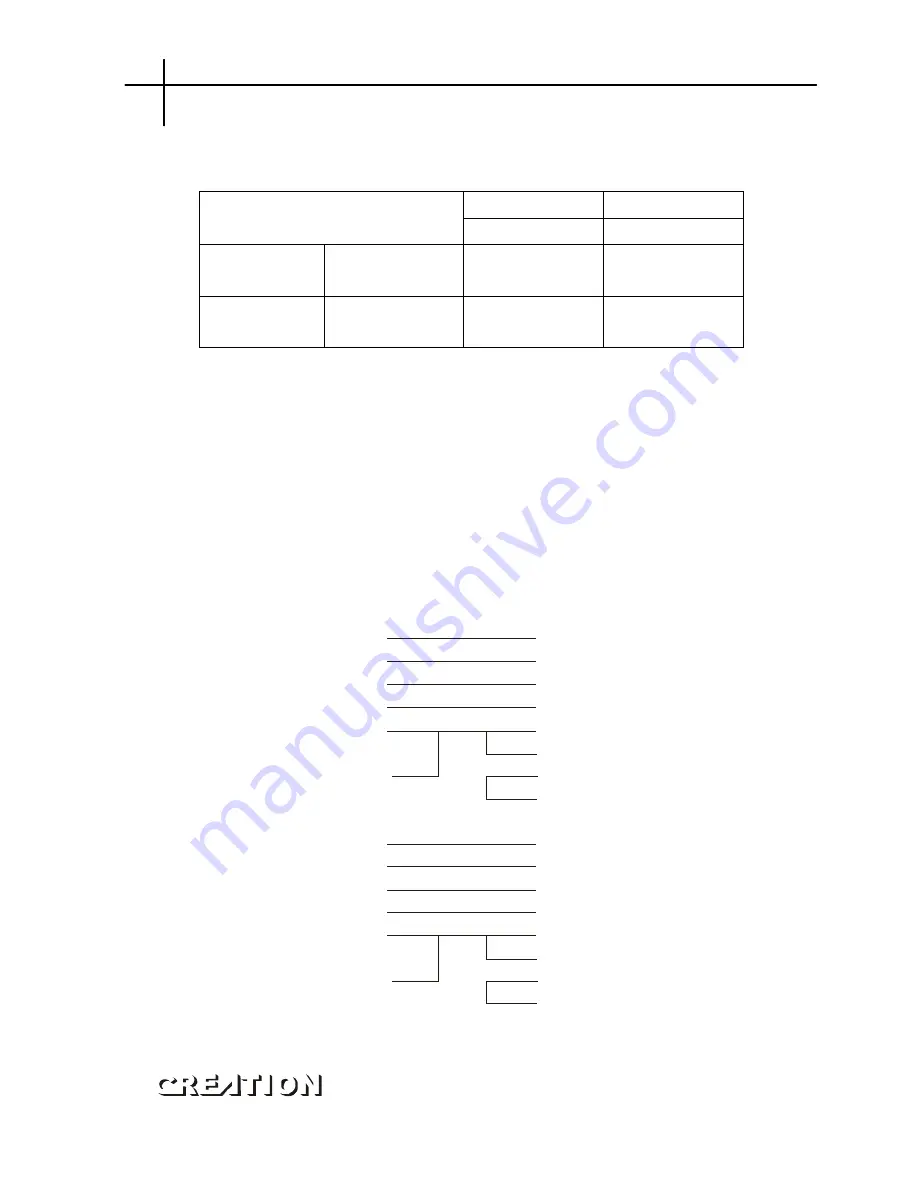

Electric parameters

:

RC

,

SD

RS

,

CS

,

DS

,

ER

Negative

Positive logic

Input voltage

level

+5v to +12v

-5v to -12v

Logical

“

0

”

Logical

“

1

”

“

ON

”

“

OFF

”

Input voltage

level

+5v to +12v

-5v to -12v

Logical

“

0

”

Logical

“

1

”

“

ON

”

“

OFF

”

¯

Connector:

Cutting plotter port: DB-25S

Signal computer port: DB-25P

¯

Map of serial interface cable connecting between IBM-PC computer and cutting

plotter

。

Cutting plotter port Signal computer port

Signal pin pin

Signal

Chassis GND

Signal GND

RX Data

TX Data

RTS

DTR

Chassis GND

RX Data

TX Data

GND

RTS

DTR

(

DB25B

)

1

7

2

2

4

20

(

DB25B

)

1

2

3

7

4

20

(

DB25P

)

N/C

7

3

3

5

8

6

20

(

DB9P

)

N/C

2

3

5

7

8

4

6

Shield

Signa GND

TX Data

RX Data

CTS

DCD

DSR

Shield

TX Data

RX Dats

GND

RTS

CTS

DTR

DSR

Features of interface

PCUT SERIES USER

‘

S MANUAL

8