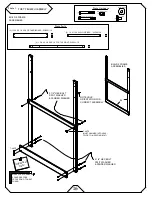

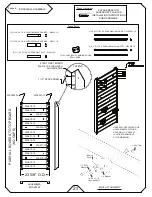

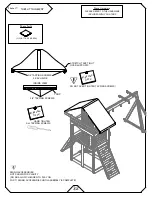

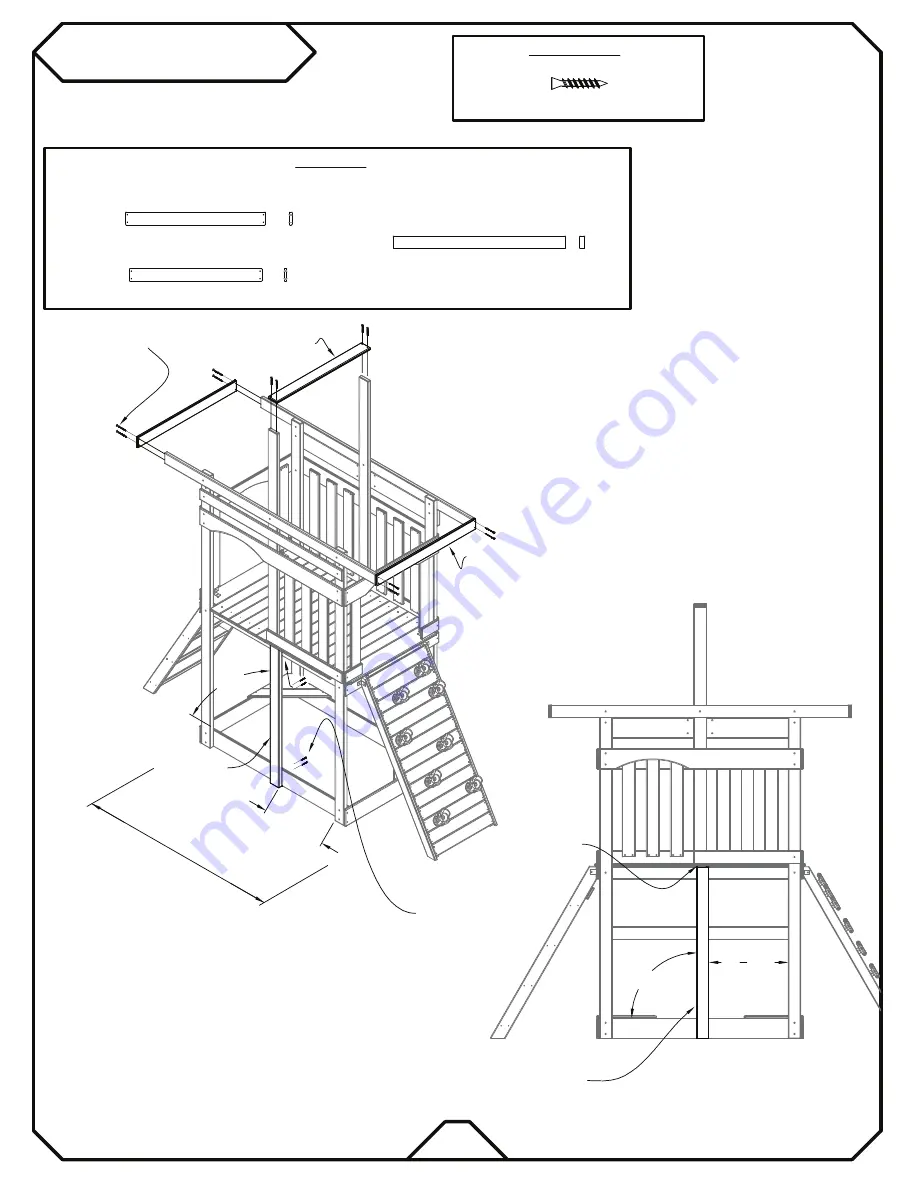

Phase 12:

27

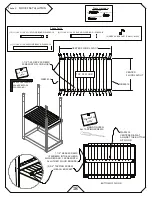

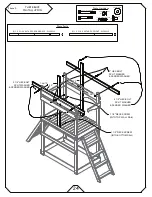

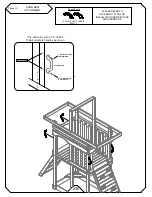

TARP SUPPORTS

LUNCH TABLE UPRIGHT

Phase Parts

Phase Hardware

WA004-10

WA003-10

WE002-10

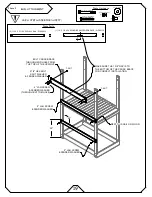

21 1/4" I.D.

ATTACH THROUGH

GROUND BOARD

INTO 'WE002-10'

1 1/2"

T-20

Deck Screws

(16)

(2) 11/16 X 3 1/2 X 37 1/2 TARP SUPPORT - WA003-10

(1) 11/16 X 3 1/2 X 35 1/2 TARP SUPPORT - WA004-10

(1) 1 3/8 X 3 3/8 X 46 1/4 TABLE UPRIGHT - WE002-10

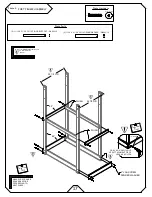

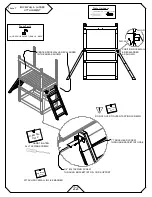

90°

FIT

UNDER FLOOR

WE002-10

DECK SCREWS

2114 I.D.

90°

SIDE

3