11

SLOW (cone 06 example)

80

°

F per hour temperature rise until the kiln reaches 250

°

F, then 250

°

F per hour until the

kiln reaches 1000

°

F, then 100

°

F per hour until the kiln reaches 1100

°

F, then 250

°

F per hour until the final 250

°

F of the fir-

ing, then 80

°

F per hour until the setpoint is reached.

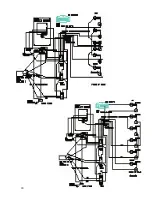

The segment profile chart for SLOW is:

SEGMENT

RATE

TEMPERATURE

HOLD

1

80

°

F

250

°

F

0

2

250

°

F

1000

°

F

0

3

100

°

F

1100

°

F

0

4

250

°

F

250

°

F below setpoint

0

5

80

°

F

setpoint

Firing time will vary according to the load density and cone selected. Thicker pieces, hand built, or hand thrown pottery,

stoneware, and porcelain are examples of ware which would be fired at this speed.

RAMP HOLD MODE

The RAMP HOLD mode is used to create custom firing profiles. If the end firing temperature is to correspond to a

pyrometric cone firing, that temperature can be retrieved from the cone table file or from the cone / temperature chart on page

26 of this manual. Keep in mind, however, that the temperature at which a given cone will bend varies according to the rate

of temperature rise and the length of hold time as well as the absolute temperature. More on the nature and use of pyrometric

cones may be found on the section on cones. It is essential to have an understanding of the properties of cones before creating

custom programs based on temperature / cone setpoints. (The firing profiles in the CONE-FIRE mode are already prepro-

grammed for optimal firing curves for each cone.)

Since it takes time for heat to soak into a piece of ceramic ware, the faster the rate of temperature rise the more the

internal temperature of the ware will lag behind the temperature in the kiln. For this reason, the last segment of a firing should

approach the desired setpoint relatively slowly (no greater than 108

°

F per hour) to allow the ware to absorb the heat and to

prevent overfiring. ( An analogy which might be helpful is to think of cooking a roast. If you roast it for a short time at high

heat, it will be seared on the outside, but “ rare” on the inside. If you roast it at a low heat for a longer time, it will be cooked

uniformly throughout. Since ceramic ware needs to be fired uniformly throughout the piece, we must approach the final tem-

perature slowly enough to allow the heat to penetrate the ware without overshooting.)