8

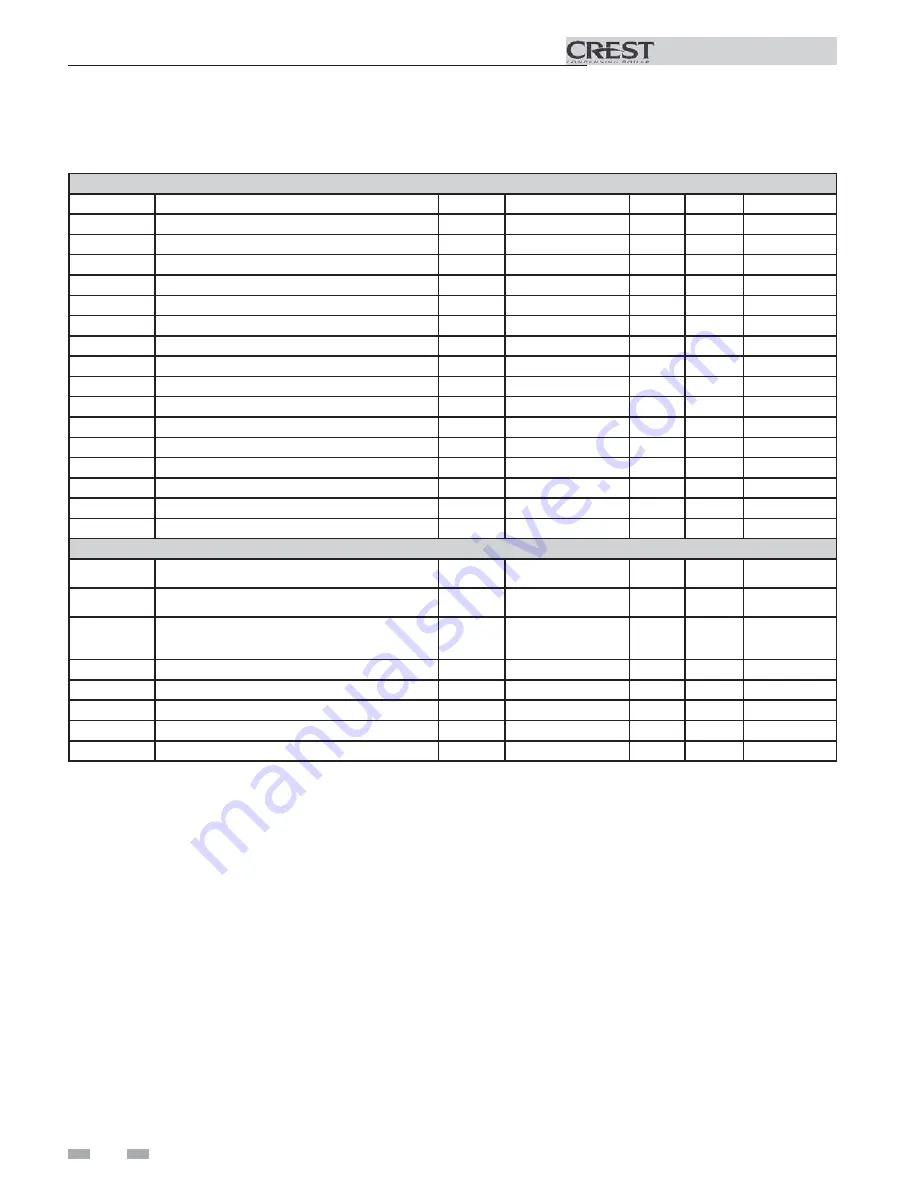

Input Registers

Address

Description

Default

Unit

Min.

Max.

Resolution

30001

Discrete Inputs 1 - 16

0

NA

0

65535

1

30002

Discrete Inputs 17 - 32

0

NA

0

65535

1

30003

Discrete Inputs 33 - 48

0

NA

0

65535

1

30004

System / Cascade Setpoint

0

Degrees Celsius

0

130

0,5

30005

System Pump Speed

0

%

0

100

1

30006

Cascade Total Power

0

%

100

800

1

30007

Cascade Current Power

0

%

0

800

1

30008

Outlet Setpoint

0

Degrees Celsius

0

130

0,5

30009

Outlet Temperature

0

Degrees Celsius

0

130

0,1

30010

Inlet Temperature

0

Degrees Celsius

-20

130

0,1

30011

Flue Temperature

0

Degrees Celsius

-20

130

0,1

30012

Firing Rate

0

%

0

100

1

30013

Boiler Pump Speed

0

%

0

100

1

30014

Boiler Status Code

0

NA

0

65535

1

30015

Boiler Blocking Code

0

NA

0

65535

1

30016

Boiler Lockout Code

0

NA

0

65535

1

Holding Registers

40001

Confi guration

0

NA

0

65535

1

40002

Coils

0

NA

0

65535

1

40003

0-10 Volt Input / Rate Command / Setpoint

Command

0

%

0

100

1

40004

Tank Setpoint

0

Degrees Celsius

0

87,5

0,5

40005

Tank Temperature

0

Degrees Celsius

-20

130

0,1

40006

Outdoor Temperature

0

Degrees Celsius

-40

60

0,1

40007

System Supply Temperature

0

Degrees Celsius

-20

130

0,1

40008

System Return Temperature

0

Degrees Celsius

-20

130

0,1

Crest Boiler Memory Map

3

Memory Map

Confi guration Bits

Address 40001 contains confi guration bits sent from the BAS to the boiler. These bits tell the boiler to use its own internal inputs,

or inputs from the BAS. When a bit is set to 1, the boiler will ignore the corresponding value contained internally, and expect

the BAS to write that value into the Holding Registers. The confi guration bits are as follows:

Bit 4: System Supply Temperature

Bit 5: Outdoor Temperature

Bit 6: Tank Temperature

Bit 7: System Return Temperature

Bit 8 - 15: Not Used (Default = 0)

Bit 0 (LSB): Boiler Enable

Bit 1: Tank Thermostat

Bit 2: Rate Command / 10 - 10V Input / Setpoint Command

Bit 3: Tank Setpoint

ModBus Instructions