6

HINTS OF OPERATION

•

During uphill compaction, it may be necessary to swing the handle over and pull the

machine slightly.

•

When compacting on a sloping terrain, the machine may tend to slide sideways. The

operator must steer toward the rise causing the machine to travel at an angle. DO

NOT operate on inclines of more than 20 degrees.

•

When operating the machine in wet or damp soil, it may occasionally be required to

clean the bottom of the base plate. Mud accumulation on the base plate will slow the

machine down and prevent efficient soil compaction.

•

When operating this compactor on asphalt surface, it is recommended that light oil or

kerosene be applied to the bottom of the base plate to prevent asphalt sticking and/or

accumulation.

•

Operating the machine on a fully compacted, hard, or non-yielding surface will cause it

to bounce and damage exciter bearings and will greatly reduce the life of the machine.

Reduce engine speed to eliminate bounce.

•

When transporting the unit ensure the fuel tap is turned OFF to prevent flooding.

STOPPING PETROL COMPACTOR

STEP 1

– Set throttle lever to LOW (starting position). Allow engine to run for 2-3

minutes.

STEP 2

– Set engine switch to OFF position. Ensure the engine stops completely.

STEP 3

– Turn fuel tap to OFF position.

STEP 4

– Cover the machine after the muffler has cooled off and keep the

compactor in a dry place.

EMERGENCY SHUTDOWN:

Move throttle lever to LOW and set engine switch to

OFF position.

STOPPING DIESEL COMPACTOR

STEP 1

– Set throttle lever to LOW (starting position). Allow engine to run for 2-3

minutes.

STEP 2

– Set engine switch to OFF position. Ensure the engine stops completely.

STEP 3

– Turn fuel tap to OFF position.

STEP 4

– Cover the machine after the muffler has cooled off and keep the

compactor in a dry place.

Summary of Contents for CC40HP

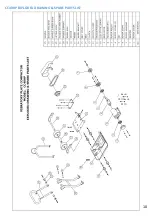

Page 10: ...10 CC40HP EXPLODED DRAWING SPARE PARTS LIST...

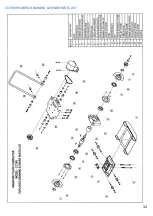

Page 11: ...11 CC60 EXPLODED DRAWING SPARE PARTS LIST...

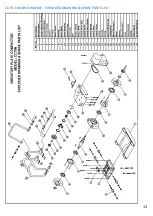

Page 12: ...12 CC70 EXPLODED DRAWING SPARE PARTS LIST...

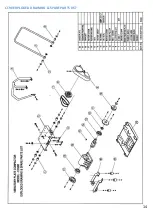

Page 13: ...13 CC70 FOLDING HANDLE EXPLODED DRAWING SPARE PARTS LIST...

Page 14: ...14 CC90 EXPLODED DRAWING SPARE PARTS LIST...

Page 15: ...15...