CROPICO LTD – DO7

Issue 7/2001

7

The measuring current polarity may be selected from the front panel. The display will indicate

or - to denote the current flow. This is particularly useful when evaluating circuits with

thermal emf or where diode effects can influence the measurement. For measurements where

thermal emf can cause a large measuring zero error, we have provided an additional automatic

average button. When pressed, the measuring current will automatically be reversed and the

average value displayed, thus eliminating the need for external computations. This average facility

will also adjust the measurement time automatically, thus giving the fastest possible measurement

even on inductive circuits.

The +ve and -ve lamps will light to indicate that the current polarity is changing. For very unstable

values where the average mode is unable to establish a stable reading, the averaging will be

aborted after approximately 25 seconds and the display will indicate - - - - A new average cycle will

be automatically initialised.

Range Selection:

The 6 ranges may be selected manually by simply pressing the desired range button. The

selected range will be indicated by an LED and over-range will be indicated by the display reading

- - - -.

Error & Status Lamps

These LEDs will light to indicate the instrument status..

LINE

:

Mains supply is connected to the instrument.

CAL

:

Calibration mode has been initialised by

the key switch and the instrument is in

calibration mode.

O/C

One of the measuring leads is open circuit

LEAD :

(too high resistance), or not connected to

test sample correctly, or the internal protection

fuse is open circuit. The lamp will always

light in standby mode.

9. METHODS OF MEASUREMENT

9.1 Ohmmeter Connections

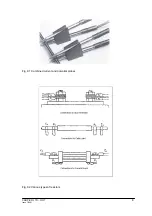

The Digital Ohmmeter type DO7 employs a four wire method of measurement, ie. it is necessary to

make four connections to the resistor under test. The instrument is supplied with four leads; two

for the potential connections which are made across the test resistor at the points between which

the resistance is to be determined; and two for the current connections which connects the test

resistor to the supply circuit.

a) Connect the black leads to the C1 and P1 terminals, and the red leads to terminals

C2 and P2.

b) Clip on to the resistor under test (fig. 9-1). Cleanliness is important and if the sample

is not clean, a rub with an abrasive paper to remove oxides is recommended.

c) It is not always possible to use the combined current and potential clips, in which

case test leads with spade tags or special test fixtures may have to be made for the

user to suit particular applications.

d) Fig. 9-2 illustrates connections to various types of test resistors.

e) When measuring 4-terminal resistance standards, do not use the combined current

and potential probes. Make four separate connections to the current and potential

terminals.

Summary of Contents for DO7

Page 1: ...DIGITAL MICROHMMETER TYPE DO7...

Page 15: ...CROPICO LTD DO7 Issue 7 2001 14...