22

23

18/09/2016

LP-OMLINK-B

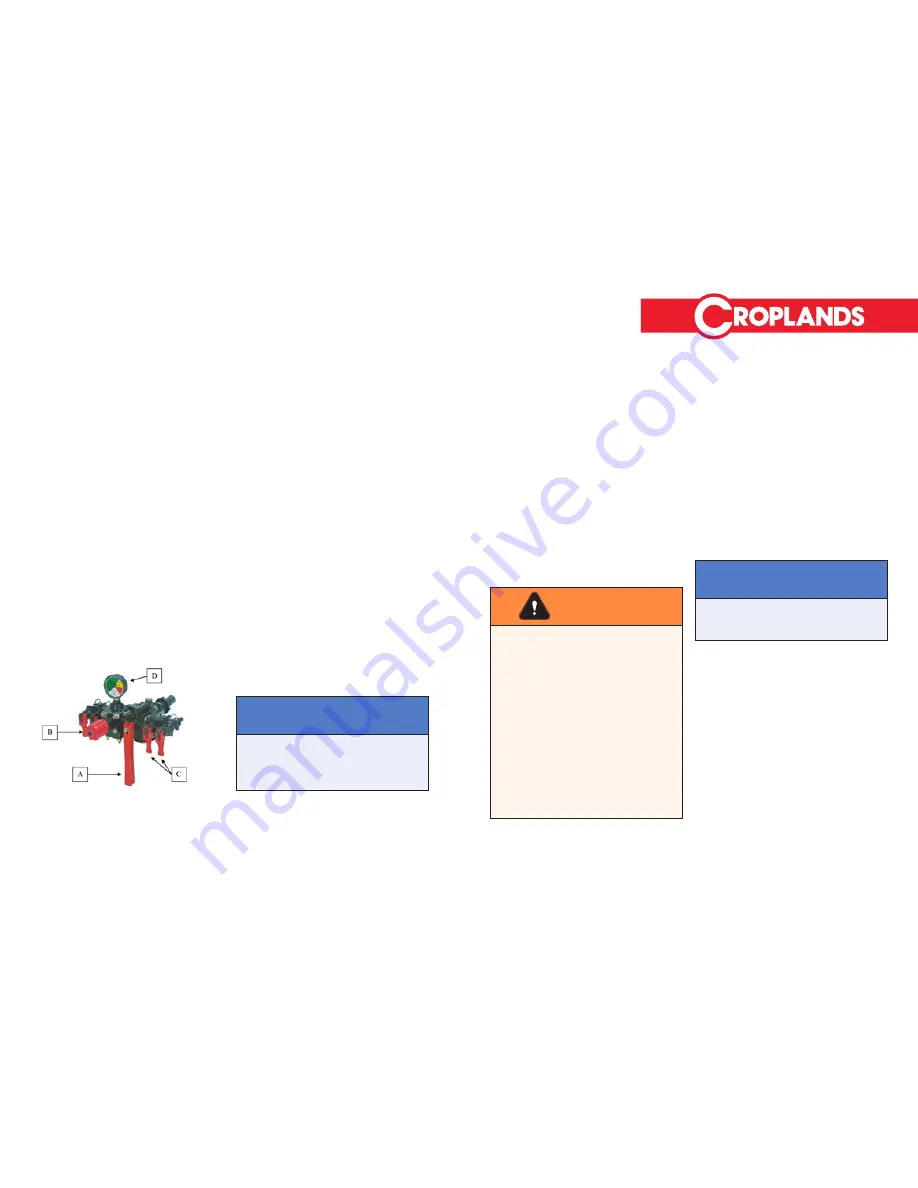

ARUCM Controller operation

A four or five outlet control unit is used (five outlet

where 3 boom sections & a hose reel is fitted) and

is standard. on all AgriPak linkage models. The

main on/off lever “A” will be used in most instances,

and when liquid supply to the boom or nozzles

is closed, all liquid will be bypassed to the tank.

System pressure is regulated by turning the red (or

on some valves black) knob “B” and by observing

the reading on the pressure gauge (D”). Turning the

knob clockwise increases the pressure and turning

anticlockwise decreases pressure. The pressure can

only be accurately set with the boom lines open

and the master lever open. Fluid is directed to the

boom lines or other spraying devices by the outlet

valves “C” which may be operated individually.

The outlet valves are marked with a “0” or a “1”

to indicate if they are on or off. If you wish to stop

spraying but leave the tractor PTO running, either

the master on/off lever or the individual taps can

be used. For a parts breakdown see the controller

manual provided.

Spray guns and hose reels (if fitted)

A variety of spray guns and hose reels are available

for use with Croplands AgriPak linkage sprayers.

A hose reel may be mounted to the side or rear

of the sprayer frame with the inlet end of the hose

connected to one outlet of the control unit. When

fitted, the standard reel contains 20 metres of 10mm

hose at a pressure rating of 20 Bar. The heavy duty

steel reel holds 30 metres of hose.

The heavy duty hose reel can hold up to 50 metres

of 10mm spray hose. For any unit has a 40-bar

pump and a hose reel fitted, the spray hose will

have the corresponding higher-rated pressure

hose fitted.

The spray lance gun fitted on the standard

Croplands hose reel is an RL10, rated up to 20 Bar

pressure. On the heavy duty reel, the standard spray

gun is a Turbo400 model rated to 50-bar pressure.

Other options include:

»

TeeJet® range of spray guns

»

Spot Gun 300

Talk to your dealer if you want a different spray gun

for a specific purpose. To operate the RL10 spray

lance or Turbo400 spray gun, start the sprayer and

have pressure available in the system. Ensure the

tap corresponding to the spray line going to the

gun is in the on position. Squeeze the main trigger

adjacent to the handle and aim the gun at the plant

to be sprayed. For the RL10, you can adjust the

spray pattern by rotating the nozzle on the end of

the lance. On the Turbo400 gun, adjust the spray

pattern with your thumb by pushing the orange side-

lever up or down. For a fine “fog” spray, the widest

angle should be selected using the side-lever, then

the orange end-cone should be adjusted to slide out

as far as possible on the gun barrel. This is ideal for

very fine spraying such as fungicide application in

nursery plants etc.

Spray Booms

A variety of booms may be used with Croplands

AgriPak linkage sprayers depending upon the

model and field application – see table on page

15-17 for this information. All have non-drip nozzle

bodies with AirMix™ flat fan nozzles. Booms are

part of the standard equipment on some models,

in some cases they may be installed by the dealer

or owner. On all types of boom, the setting of the

correct operating height is most important to achieve

a uniform spraying pattern. This needs to be at a

height above the target which will achieve 50%

overlap of the spray from adjacent nozzles.

WARNING

Safety information about Spray guns

and lances:

1. NEVER aim the spray gun at anyone

2. ALWAYS shut the system off when you

are not using the spray gun

3. ALWAYS ensure your spray application

is not drifting beyond the target

4. NEVER operate the gun beyond the

pressure capability of the system

Secure the gun on the spray unit and roll

up the hose when the job is finished.

NOTE

For more information on hose reels and

spray guns fitted to your sprayer, please

see the Croplands Reels & Spray Guns

Operator and Parts Manual.

NOTE

Section 6 will only be relevant if your

AgriPak Linkage sprayer is fitted with a

Croplands boom.