24

25

18/09/2016

LP-OMLINK-B

SECTION 6: SPRAYING

INFORMATION

This section also provides information

relevant to Calibrations in section 7

When to spray

Spraying results are best when the wind speed and

the temperature are low but the relative humidity

is reasonably high. An ideal time is at sun up or

nearing the end of the day when these conditions

are more likely to occur.

For more information, contact Croplands about our

SprayWise® program, or purchase a copy of the

SprayWise Application Guide from Croplands.

Also, the use of the WINDMATE™ Wind meter

would be of excellent value to anyone doing

regular spraying.

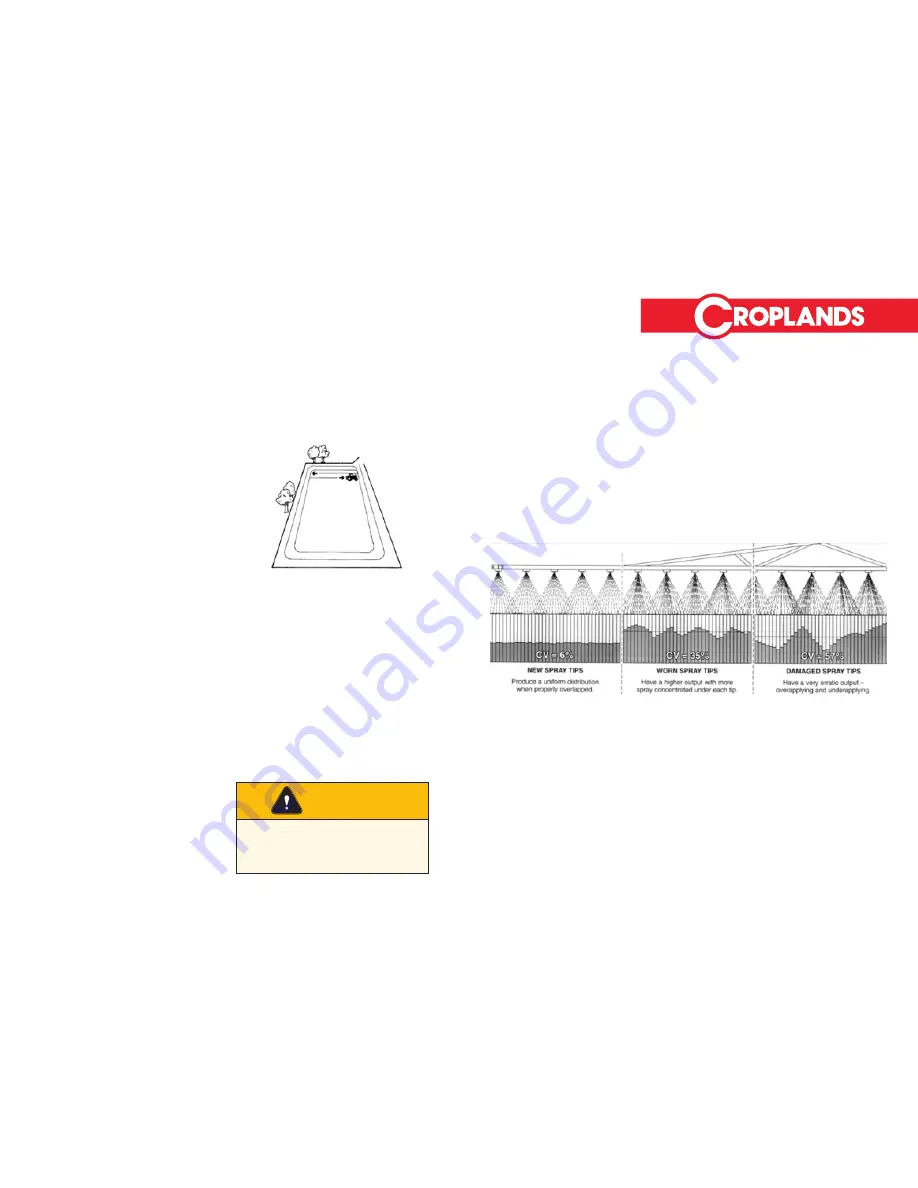

Field patterns

For the best coverage, spray two swath widths

around the outer perimeter of the field as shown

in the diagram. This establishes a good headland

and will give you adequate room to turn around.

Turn the booms off when you come back on to the

headland to prevent over spraying and wastage.

Using a guidance system such as GPS or foam

markers can prevent overlaps and ensure you get

better coverage.

Ground Speed

Modern tractors should have sufficient speed

accuracy for sprayers of this size. To check the

speed, fill the tank and open the boom to simulate

usual spraying conditions. See section 7 to learn

how calculate ground speed if your tractor does not

have a reliable speedometer.

For spraying with an AgriPak linkage sprayer, the

speed will you can safely & accurately spray at

will depend on the conditions, terrain, and product

being applied. In general, speeds of 5 to 15 km/hr

are most often within the range for linkage spraying.

Spray Quality

Spray quality is becoming extremely important for

the correct application of chemicals. Refer to your

advisor, local DPI or check the Croplands Buyers

Guide for more information. Many chemical labels

now specify the spray quality required for the

product being used. Loosely, spray quality falls into

a droplet range of:

»

Ultra Coarse

»

Extremely Coarse

»

Very Coarse

»

Coarse

»

Medium

»

Fine

»

Very fine

Field patterns

CAUTION

Most spray applications will fall into the

Medium to Very Coarse range, depending

on the application. Talk to a qualified

Agronomist or Advisor if uncertain.

Nozzle spacing and height

Nozzles overlap should be 50% at the point of

contact with the spraying surface. Croplands booms

operate with a nozzle spacing of 500mm (50cm)

with nozzles slightly offset to avoid interference.

Nozzles are supplied with 110° angled patterns.

The recognized height to achieve the required

50% overlap is 400mm-500mm for 110° nozzles

(measured from the target to be sprayed).

Spray pattern and uniformity

Your nozzle spray pattern, overlap and uniformity

need to be monitored and can be tested in the

following manner. Keep a spare new nozzle to with

which you can compare the other nozzles on your

unit. Place the new nozzle at a central point on the

boom and fill the tank with fresh, clean water and

switch the boom on. Examine the spray patterns

against a dark background and replace any that

show signs of damage or sufficient wear as shown

below.