6

7

18/09/2016

LP-OMLINK-B

SECTION 3: SAFETY

INFORMATION

Rules for Safe AgriPak Sprayer Operation

»

Always read your sprayer operator’s manual

thoroughly before operating. Accidents occur

every year because of careless use of farm

chemicals and farm machinery. You can avoid

these hazards by observing these safety

instructions.

»

Dispose of all chemical containers as per

instructions on label. Failure to do so could result

in contaminating the environment with chemicals.

»

Inspect hose and hose connections daily. Always

wear rubber gloves when tightening connections.

Damaged, loose or worn hoses could result in

operator being exposed to toxic chemicals, which

could result in serious illness or faulty sprayer

operation.

»

Always use the proper application rate. To

assure proper application rate calibrate

sprayer correctly. The wrong application rate

of a pesticide or herbicide concentration that

is too high may expose the operator and the

environment to danger.

»

Be sure to disconnect all power connections (if

applicable) before attempting welding repairs.

»

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Failure to

do so could result in serious injury.

»

When working on your sprayer, always stay out

from under the sprayer unless it is resting on the

ground or supported on solid blocks. Hydraulics

or jacks could fail letting the sprayer fall. This

could result in pinning or crushing of personnel.

ALWAYS have the booms folded and in the

parking position when working on the sprayer.

»

Check the entire sprayer, prior to each use, for

any loose bolts or mechanical connections. These

precautions can prevent injury to personnel and

damage to equipment.

»

Use only genuine Croplands parts for any

necessary replacement. All parts are important

to the equipment design. Homemade parts

may look the same but might be dangerous in

operation.

»

Follow the chemical manufacturers precautions

before cleaning the sprayer. Exposure to

chemicals could result in serious illness or death.

»

Always wear gloves and wash the sprayer before

doing any disassembly repair work. Chemical

residues on the machine parts could contaminate

operator or service personnel causing serious

illness.

»

Always relieve system pressure before doing

any work on the machine. Failure to do so could

cause operator to be exposed to high pressure

spray of chemical resulting in serious injury or

machine damage.

»

Always be sure all guards are properly installed

on machine before operating. Failure to do so

could result in entanglement in moving parts

resulting in serious injury to operator.

»

Always keep PTO guards in place. Failure to do

this might result in entanglement. This is a leading

cause of serious accidents & death on farms.

»

Do not ride on machine when in motion. This is

an unsafe practice and can lead to serious injury

should the rider fall from the sprayer or tractor.

»

Always stand well clear of sprayer when

operating. Any particle or spray drift is dangerous

and may be hazardous to humans.

»

Do not disconnect any hoses nozzles or filters

while sprayer is operating. Disconnecting

components while under pressure will result in

uncontrolled spray discharge, which may be

hazardous.

»

Should any welding be required on the steel

parts of the sprayer, always clean the linkage

sprayer and disconnect the power before doing

any repairs. Cover rubber hoses, and all other

flammable parts. Keep a fire extinguisher near

the sprayer when welding. Have good ventilation

when grinding or welding painted or galvanised

parts. Wear dust mask when grinding. Toxic dust

or gas can be produced.

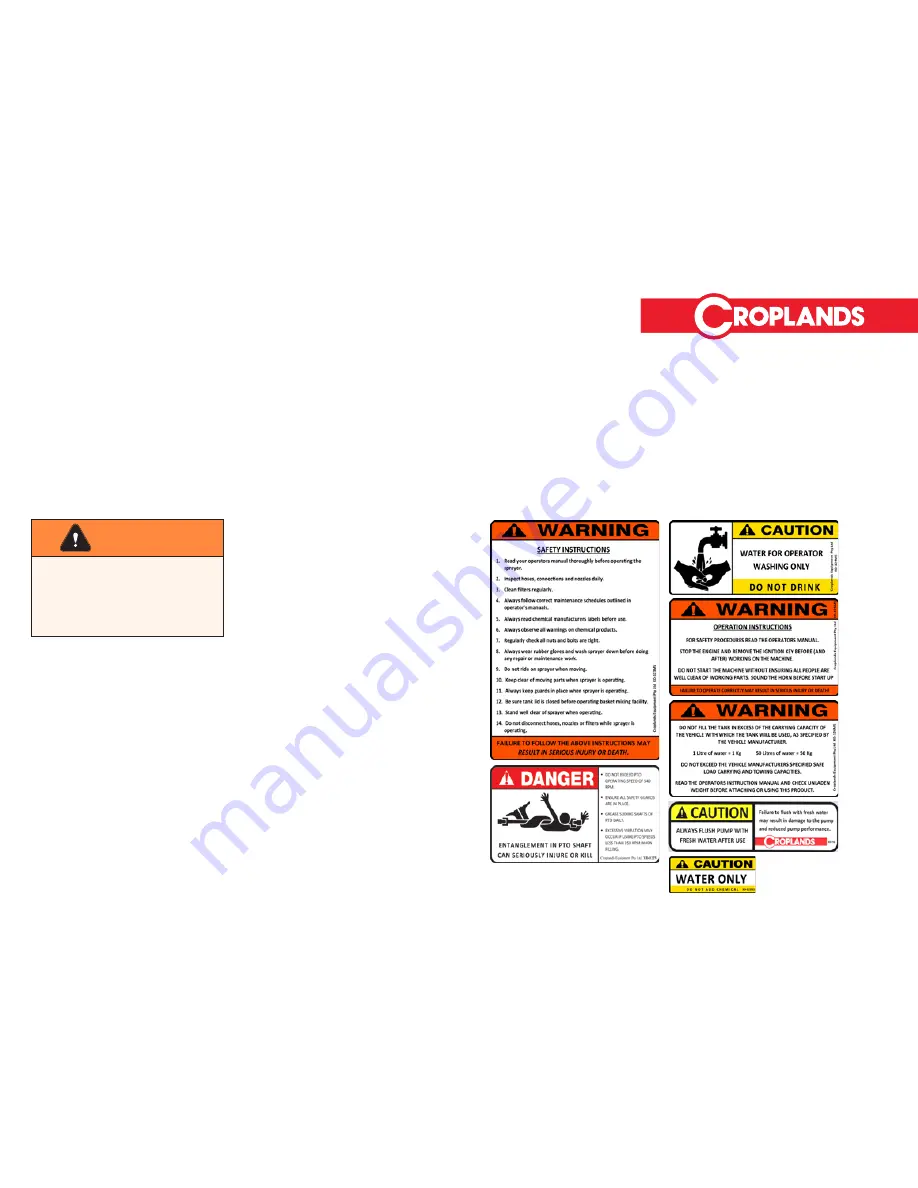

SAFETY DECALS

WARNING

PTO shafts in particular are

extremely dangerous, ensure the

PTO is disengaged prior to doing any

adjustment or work on your sprayer.

Never operate the PTO if any person is

near the sprayer.