2-1-1

U29PHSMEN

STANDARD MAINTENANCE

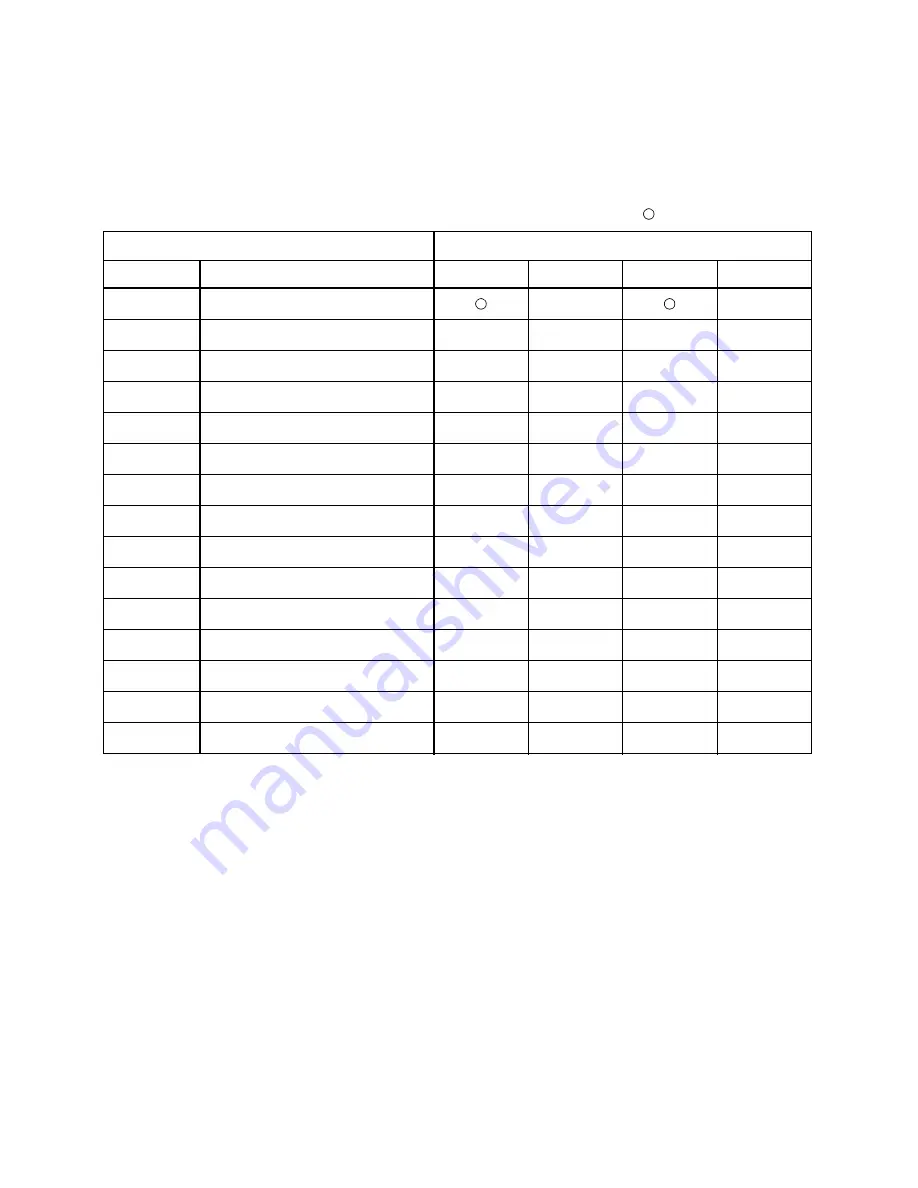

Service Schedule of Components

This maintenance chart shows you the standard of replacement and cleaning time for each part.

Because those may replace depending on environment and purpose for use, use the chart for reference.

Notes:

1.Clean all parts for the tape transport (Upper Drum with Video Head / Pinch Roller / ACE Head / FE Head) using

90% lsopropyl Alcohol.

2.After cleaning the parts, do all DECK ADJUSTMENTS.

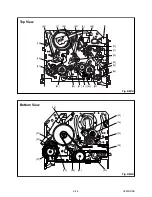

3.For the reference numbers listed above, refer to Deck Exploded Views.

* B73 ------ Recording model only

* B86 ------ Not used in 2 head model.

H: Hours

: Cleaning

I

: Replace

Deck

Periodic Service Schedule

Ref.No.

Part Name

1,000 H

2,000 H

3,000 H

4,000 H

B2

Cylinder Assembly

I

I

B3

Loading Motor Assembly

I

B8

Pulley Assembly

I

I

B587

Tension Lever Assembly

I

I

B31

ACE Head Assembly

I

B573, B574

Reel S, Reel T

I

B37

Capstan Motor

I

I

B52

Cap Belt

I

I

*B73

FE Head

I

*B86

F Brake Assembly (HI)

I

I

B133

Idler Assembly (HI)

I

I

B410

Pinch Arm Assembly

I

I

B414

M Brake (SP) Assembly (HI)

I

I

B416

M Brake (TU) Assembly (HI)

I

I

B525

LDG Belt

I

I

Summary of Contents for F5000M

Page 22: ...1 8 3 1 8 4 HG232SCM1 Main 1 5 Schematic Diagram...

Page 23: ...Main 2 5 Sensor Schematic Diagrams 1 8 5 1 8 6 HG232SCM2...

Page 24: ...Main 3 5 Schematic Diagram 1 8 7 1 8 8 HG232SCM3...

Page 25: ...Main 4 5 Jack Schematic Diagrams 1 8 9 1 8 10 HG232SCM4...

Page 29: ...1 8 17 1 8 18 Jack CBA Top View Jack CBA Bottom View BHG470F01014C...

Page 35: ...1 13 1 HG232FEX EXPLODED VIEWS Front Panel A1X...

Page 69: ...F5000M HG232ED 2004 04 22...