BWC Series

INSTALLATION INSTRUCTIONS

! "#!$

%&

'

BWC150

'

BWC225

()*+*

: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury,

or loss of life. For assistance or additional information, con-

D

E S I G N E D T O

L

E A D

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

www.crownboiler.com

Summary of Contents for BIMINI BWC150

Page 2: ......

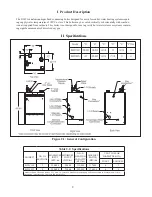

Page 8: ...6 v v _ j j 0 Q...

Page 12: ...2 K M 4 M 4 4 2 K 4 4 2 K 2 4 7...

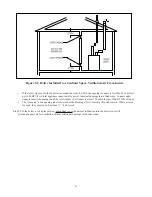

Page 13: ...11 Z0 Z J0 0 Z J0 Z J0 Z 0 v Q q v Qj v Qj v Q j 0 Q Z 0 j 0 0 3 0 2 4 5 Q6...

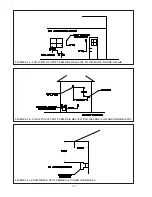

Page 17: ...15 F0 0 v 5 v v 0 0 5 0 j Qj J J0 0 0 q 0 0 0 7 Z J 5 7 7...

Page 18: ...16 2 F0 z z 0 v 7 Q 7 7 v j v z z 0 0 5 0 j j Z 0 0 0 q 0 0 z 7 0 F j q0 0 0 q0 z 0 0...

Page 19: ...17 0 7z 0 7z 7z q v 7 v v Z v 0 _ j Z 0 j j j Q j q Z 0 0 7z q 2...

Page 20: ...0 0 v 5 j Fj v v Z v 0 j q Z 0 0 q 0 0 0 0 0 0 2 Z0 0 0 0 q q...

Page 22: ...Q PAGE INTENTIONALLY 7 BLANK...

Page 23: ...21 PAGE INTENTIONALLY 7 BLANK...

Page 24: ...22 PAGE INTENTIONALLY 7 BLANK...

Page 25: ...National Fuel Gas Code J 5 q q Q Q Q 23...

Page 28: ...7 0 J Q Z 7 F J Q Q J 7 Z J F 26...

Page 29: ...K 7 _ M 7 27...

Page 30: ...M 7 5 6 0 5 6 Q...

Page 32: ...F 4 7 0 4 7 0 5 0 6 0...

Page 34: ...32 F0 0 0 5 0 0 7 0 Z0 0 7 J0 0 0 0 7 5 q Q Q 0 0 _ j 0 0 0 5 0 Q Q0 0 4 0 v v v Q0 q F0...

Page 35: ...33 30 M 7 3...

Page 37: ...M 4 35...

Page 38: ...4 36...

Page 39: ...K M 0 7 37...

Page 44: ...42 7 0 4 0 QQ Q Q0 0 _ j _ _ _ j 4 4...

Page 46: ...a 0 _ j _ j q 5 Q0 v 5 v v 5 F Q 0 _PArAj 0 _Infoj 0 _Stbyj _ j 0 Q 4 0 0 44...

Page 50: ...J0 0 Q 0 0 0 0 0 F 0 0 5 0 5 5...

Page 52: ...0 5 q 5 5 k k Z...

Page 56: ...54 PAGE INTENTIONALLY 7 BLANK...

Page 57: ...55 a F...

Page 60: ......

Page 61: ...59...

Page 62: ...Z...

Page 63: ...61 57 0 6...

Page 64: ...54 6 62...

Page 66: ...64...

Page 68: ...66...

Page 69: ...67...

Page 70: ...Z...

Page 71: ...69 3 M Q 0 0 JQ Q 7 0 Q F JQ Q 7 0 QJ _ 5 j Q 0 0 JQ Q 7 0 JQ Q 7 0...

Page 72: ......