INSTALLATION AND OPERATION MANUAL, DIRECT STEAM SINGLE & TWIN MIXER

KETTLE, MODELS DLTM-40 TO DLTM-100 AND DLTM-40-2 TO DLTM-100-2

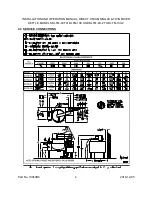

4.0 INSTALLATION INSTRUCTIONS

The kettle must be installed in accordance with State and/or local codes. In the USA, the

National Electrical code, ANSI/NFPA-70 (latest edition). In Canada, the Canadian Electrical

Code, Part 1, CSA Standard C22.1 (latest edition).

1.

Select a location to provide drainage for kettle pour path when tilted and for butterfly valve

if so equipped. Allow sufficient rear clearance from wall for access to rear service panel on

hydraulic console.

2.

Level unit. Mark anchoring hole locations through flanged adjustable feet.

3.

Remove unit and drill holes as marked and, insert expansion shields to accommodate

5/16" size lag bolts.

4.

Reposition unit. Re-check level.

5.

Bolt down unit and seal bolts with Silastic or equivalent sealing compound. Sealant must

be applied not only to bolt heads but also around flanges making contact with the floor

surface to fulfil NSF requirements. Wipe off excess sealant immediately.

6.

Connect steam line (3/4" pipe size) to the steam inlet. Make sure there is a steam control

valve strainer convenient to the unit. If incoming steam pressure is greater than kettle

maximum operating pressure, then a pressure reducing valve must be installed in the line.

If large amounts of water accumulate in the steam line it will be necessary to install one or

more ball float traps in the line to eliminate the water. A steam line pressure gauge is also

recommended to determine the actual amount of steam coming to the kettle.

7.

Connect the condensate return line to a drain or to the boiler return line. Return line must

have a check valve.

8.

Connect cold water supply line as indicated in bottom of hydraulic console.

9.

A control box with a power supply equivalent to the electrical rating of the unit should be

located nearby. A waterproof electrical connection for the power supply to the unit must be

provided.

10. Connect power supply as indicated.

11. Relief valves on the kettles must not be adjusted or closed off as they are set to relieve

excess pressure in the kettles.

12. Do not make any adjustments to the hydraulic valves as they have all been adjusted at the

factory.

13. Turn unit on when electrically connected, and check for proper operation.

Part No. 10040R4

7

2018-12-05