8-12

520 Express Series

520 Express Series

GENERAL MAINTENANCE

Power Train

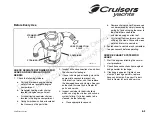

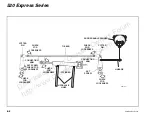

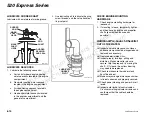

COUPLING ALIGNMENT

Slight coupling misalignment can cause

vibrations, loss of power and damage to

crankshaft bearings. Check coupling

alignment using the following procedure:

1. Remove the coupling bolts and slide the

coupling apart only slightly.

2. Measure the gap between the coupling

halves at four places 90° apart with a

feeler gauge. The difference in the

readings must not exceed 0.003 inches

(0.08 mm).

3. Adjust the adjustable engine mounts,

until engine and coupling are in

alignment. See your Cruisers Yachts

Dealer if necessary.

4. Leave coupling half on transmission

stationary and rotate the propeller shaft

1 turn, in 90° intervals. At each 90°

interval, check the clearance between

the coupling halves. If the four

measurements differ by more than 0.003

inches (0.08 mm), the propeller shaft

may be bent.

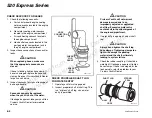

PROPELLER REPLACEMENT

WARNING

Avoid accidental starting of the

engines when changing propellers.

Remove the keys from the ignition

switches.

Protect your hands. Propellers can

have sharp edges and are heavy.

Handle with care.

The following steps represent a typical

propeller installation procedure. Refer to the

propeller manufacturer’s recommended

procedure if different.

1. Remove any small burrs on tapered end

of propeller shaft using a honing stone.

2. Apply a thin layer of Prussian Blue

blueing compound on the tapered

section of the shaft.

3. Slide the propeller on the shaft and

rotate it slightly on the shaft. Remove the

propeller.

4. The blueing will be gone where the

propeller contacts the shaft. About 60%

contact is required between the propeller

and the shaft. If sufficient contact area is

obtained, go to Step 7.

5. If the contact area is small, apply a

course valve grinding compound to the

taper of the shaft. Install the propeller

and rotate it on the shaft clockwise and

counterclockwise about 100 times.

6. Remove the propeller and clean the

grinding compound from the shaft and

propeller. Repeat Steps 2 to 4.

7. Apply a light layer of waterproof grease

to taper area of shaft.

8. Install the key and propeller on the shaft.

The key should fit tight from side to side.

There should be a slight clearance

between the top of the key and the

groove in the propeller. If there is no

clearance, the propeller can be forced off

center causing vibration.

9. Drive the propeller all the way up the

shaft by installing and tightening the

large nut.

10. Install the small nut. Hold the large nut

while tightening the small nut to lock the

nuts in place. Install the cotter pin and

bend the ends over to hold it in place.

CSR161-36A

COUPLING

TRANSMISSION

MISALIGNED COUPLING

Downloaded

from

Cruisers

Owners

Forum

http://www.CruisersOwnersForum.com