Assembly Instructions

40' Drill

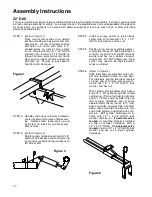

STEP 11 Attach pull bar slides to each side of A-

frame in front of cross tube with

1/2" x 4 1/2" HHCS, lock washer, and hex

nut.

STEP 12 Install a 3" x 8" hydraulic cylinder (base

end to frame -- ram end to wheel lug --

ports to top of drill) to wing wheel

rockershaft. Install 5-bolt rim and tire

assemblies to hubs. Follow the same

procedure on opposite wing rockershaft.

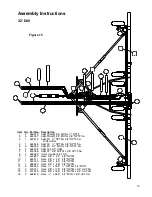

STEP 13 Mount selector valve plate to selector

valve bracket with two (2) 3/8" x 1" HHCS,

nuts, and lock washers. Attach valve to

plate with two (2) 5/16" x 1" HHCS and

lock washers. Valve is mounted with

handle up and two port side forward. Intall

fittings and hoses

per Figure 13 on page 4

.

Use hose clamps to attach hoses along

front of frames. These are attached to

walkboard and tooth clamp bolts. Cable

wrap and hose carriers hold hoses which

are routed down top of A-frame. Slack in

hoses going to wing cylinders is needed at

the hinge. Attach a hose clamp on front

bolt of inside wing box standoff to hold

hoses up over hinge area.

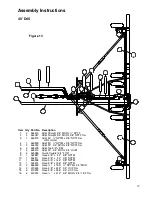

STEP 14 WING LEVEL ADJUSTMENTS. Activate

hydraulics to wing and center frame cylin-

ders to raise drill. Level top of 4" x 6"

center frame tube using hitch jack.

(Refer

to Figure 14.)

Check each wing about

midway out on 4" x 6" tube to make sure it

is level. If wings require leveling, remove

two (2) 3/8" bolts which hold large hex

plate on top of hinge. Loosen set screw in

side of 1 1/2" hex nut and loosen nut.

Hinges are set at factory at zero degrees.

This is indicated by two small holes in

hex plate pointing outward toward

wing.

To tip wing FORWARD, turn indica-

tor holes to front of drill. To tip wing

BACKWARDS, turn indicator holes to back

of drill. Level both wings and re-secure

3/8" bolts, 1 1/2" nut, and set screws.

STEP 15 FOLD ADJUSTMENTS. Install cylinder

lockout in center frame cylinder and se-

cure with 5/16" x 2 3/4" pin. Switch selec-

tor valve to fold cylinder. Slowly fold drill

checking for clearances and binding. If

wings do not fold fully, adjust clevis on end

of fold cylinder. Screw out to fold further,

and in so wing does not fold in as far.

Raise latches on wing carrier and secure

with 3/4" pins. Raise wing wheels and drill

is ready for transport.

Figure 14

16

Summary of Contents for 3200

Page 1: ...3200 Trash Shank OWNER S MANUAL 01 10 601401 ...

Page 5: ...Safety RECOGNIZE SAFETY INFORMATION UNDERSTAND SIGNAL WORDS FOLLOW SAFETY INSTRUCTIONS 3 ...

Page 6: ...Safety OPERATE SAFELY AVOID TIP OVERS KEEP RIDERS OFF MACHINE 4 ...

Page 7: ...Safety HANDLE FUEL SAFELY AVOID FIRES PREPARE FOR EMERGENCIES WEAR PROTECTIVE CLOTHING 5 ...

Page 8: ...Safety USE SAFETY LIGHTS AND DEVICES TRANSPORT SAFELY 6 ...

Page 9: ...Safety TOW LOADS SAFELY PRACTICE SAFE MAINTENANCE 7 ...

Page 10: ...Safety AVOID HIGH PRESSURE FLUIDS CHARGE ROW MARKER HYDRAULIC SYSTEM 8 ...

Page 34: ...32 A Frame 32 ...

Page 36: ...40 A Frame 34 ...

Page 38: ...Center Frame Section 36 ...

Page 40: ...32 Left Wing Section 38 ...

Page 42: ...32 Right Wing Section 40 ...

Page 44: ...40 Left Wing Section 42 ...

Page 46: ...40 Right Wing Section 44 ...

Page 48: ...Center Drive Assembly 46 ...

Page 50: ...Left Drive Assembly 48 ...

Page 52: ...Right Drive Assembly 50 ...

Page 54: ...Box Assembly 52 ...