Identification

Your CrustBuster® drill is identified by a Serial Number and Model Number. Record

these numbers in the spaces provided in this manual and refer to them when ordering

parts or requesting service.

Serial Number

Model Number

Warranty

WARRANTY

: In addition to the implied warranties of fitness and of merchantability,

CrustBuster®/Speed King, Inc. warrants new products sold by it to be free from defects in

workmanship and material for a period of 12 months, from the date of delivery to the first user

customer. Warranty on purchased parts (cylinder, blades, bearings, shanks, etc.) will be the

same as that offered by the appropriate manufacturer of these parts.

EXCLUSIONS

: No warranty of any kind is made by CrustBuster®/Speed King, Inc. with

regard to new products which have been subject to operation in excess of recommended

capacities, misuse, abuse, negligence, or accident, or have been altered or repaired in any

manner not authorized by CrustBuster®/Speed King, Inc. CrustBuster®/Speed King, Inc. is

constantly striving to improve its products. Changes in design and improvement will be made

whenever CrustBuster®/Speed King, Inc. believes the efficiency of its products will be

improved thereby, but without incurring any obligation to incorporate such improvements in

any products which have been shipped or are in service. No obligation exists for

compensation of unauthorized repairs or modifications without prior approval. And in no event

will CrustBuster®/Speed King, Inc. be liable for consequential damages, such as but not

limited to: downtime, delayed or late tillage or planting, etc.

WARRANTY REGISTRATION

: This warranty is not valid unless registered with

CrustBuster®/Speed King, Inc. within 10 days from the date of purchase. It is the sole

responsibility of the selling retail dealer to fill out the registration forms and see that they are

properly filed with CrustBuster®/Speed King, Inc.

WARRANTY PROCEDURE

: Should any part fail to conform with this warranty,

CrustBuster®/Speed King, Inc. will repair or replace the part or parts which do not conform.

If a part is defective, take it to your authorized CrustBuster® Farm Equipment Dealer

immediately, along with your warranty registration, and complete the proper forms requesting

a warranty adjustment. Our representative will pick up the part to be returned to the factory

for examination. If the customer (first user) requests that a new part be substituted for the old

part, a new part will be charged to the dealer who will in turn charge the customer. If the part

is found by us to be defective, a credit for the part will be given to the dealer to be passed on

to the customer. If the dealer or customer wishes to repair the part, this will be done only if

authorized by CrustBuster®/Speed King, Inc. This warranty procedure is in addition to all

remedies authorized by law.

CRUSTBUSTER®/SPEED KING, INC.

Box 1438

Dodge City, KS 67801

Specifications are subject to change without notice.

®

is a registered trademark of CrustBuster/Speed King, Inc.

Summary of Contents for 3200

Page 1: ...3200 Trash Shank OWNER S MANUAL 01 10 601401 ...

Page 5: ...Safety RECOGNIZE SAFETY INFORMATION UNDERSTAND SIGNAL WORDS FOLLOW SAFETY INSTRUCTIONS 3 ...

Page 6: ...Safety OPERATE SAFELY AVOID TIP OVERS KEEP RIDERS OFF MACHINE 4 ...

Page 7: ...Safety HANDLE FUEL SAFELY AVOID FIRES PREPARE FOR EMERGENCIES WEAR PROTECTIVE CLOTHING 5 ...

Page 8: ...Safety USE SAFETY LIGHTS AND DEVICES TRANSPORT SAFELY 6 ...

Page 9: ...Safety TOW LOADS SAFELY PRACTICE SAFE MAINTENANCE 7 ...

Page 10: ...Safety AVOID HIGH PRESSURE FLUIDS CHARGE ROW MARKER HYDRAULIC SYSTEM 8 ...

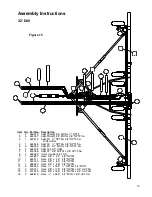

Page 34: ...32 A Frame 32 ...

Page 36: ...40 A Frame 34 ...

Page 38: ...Center Frame Section 36 ...

Page 40: ...32 Left Wing Section 38 ...

Page 42: ...32 Right Wing Section 40 ...

Page 44: ...40 Left Wing Section 42 ...

Page 46: ...40 Right Wing Section 44 ...

Page 48: ...Center Drive Assembly 46 ...

Page 50: ...Left Drive Assembly 48 ...

Page 52: ...Right Drive Assembly 50 ...

Page 54: ...Box Assembly 52 ...