12

Lubrication and Service

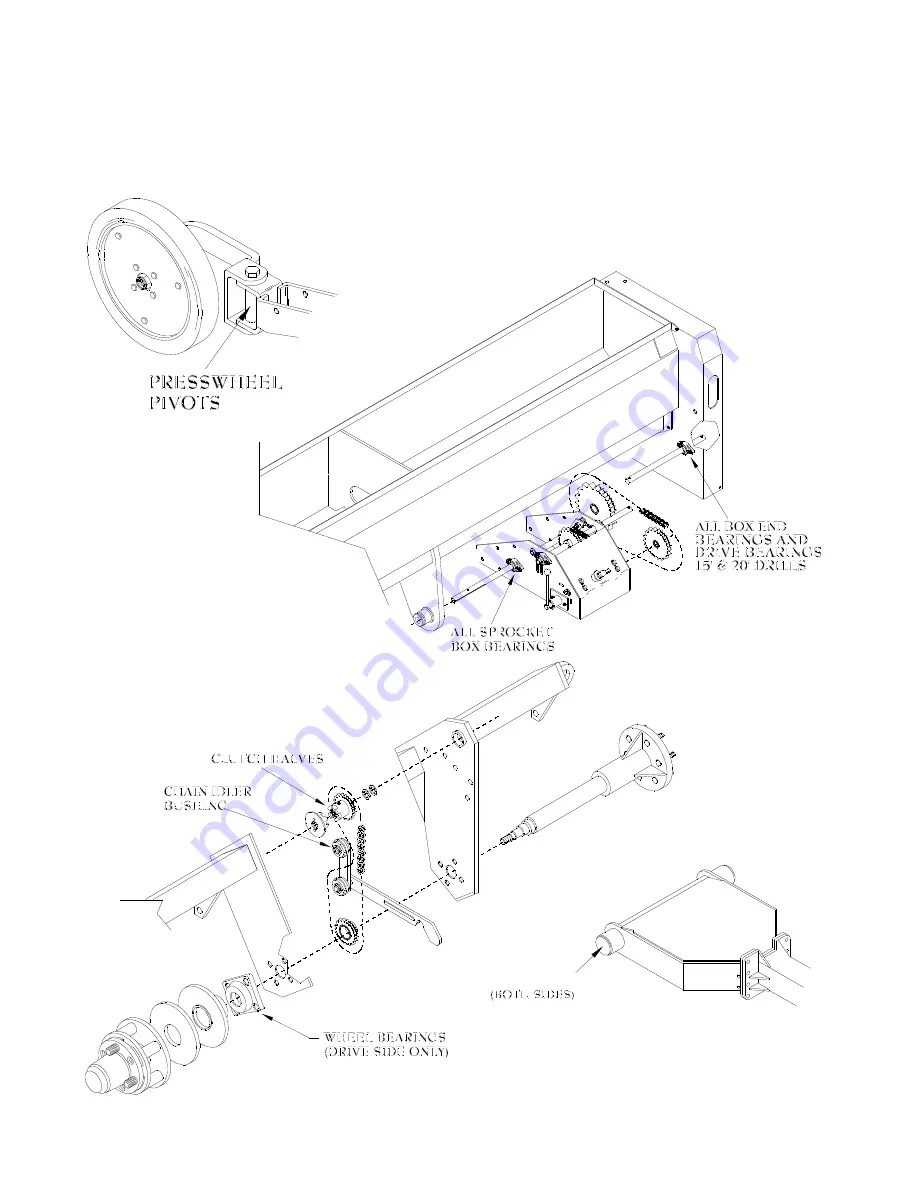

Proper maintenance will extend the life of your

drill. Refer to the drawings below for lubrication

requirements. Use a high quality grease in

bearings and pivot points. On greaseable

sealed bearings, be careful not to over grease

and destroy the dirt seal. Oil chains with a chain

lube. A light penetrating oil or liquid graphite

should be used on seed cups initially and at the

end of each season.

NOTE:

See gear box assembly on

page 34 for zerk locations.

Summary of Contents for 4600 Series

Page 1: ...4600 SERIES ALL PLANT DRILL 09 03 605717 ...

Page 6: ...4 Safety Instructions ...

Page 7: ...5 Safety Instructions ...

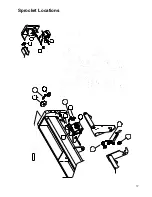

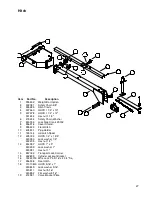

Page 19: ...17 Sprocket Locations ...

Page 20: ...18 ...

Page 34: ...32 Grain Box 10 ...

Page 36: ...34 Grain Box 15 20 ...

Page 44: ...42 All Plant Opener Assembly ...

Page 46: ...44 Gear Box Assembly 10 ...

Page 48: ...46 Gear Box Assembly 15 20 ...

Page 61: ...58 a Harrow Layouts 10 Drill 7 Spacing 10 Drill 10 Spacing ...

Page 62: ...58 b ...

Page 63: ...59 15 Drill 8 Spacing 15 Drill 7 Spacing Harrow Layouts ...

Page 64: ...60 15 Drill 10 Spacing 20 Drill 7 Spacing Harrow Layouts ...

Page 65: ...61 20 Drill 8 Spacing 20 Drill 10 Spacing Harrow Layouts ...

Page 66: ...62 15 Legume ...

Page 68: ...64 20 Legume ...

Page 71: ...67 Light System ...

Page 72: ......

Page 73: ...69 Fertilizer Unit ...

Page 76: ...72 4615 Sprocket Locations Fertilizer Unit ...

Page 78: ...74 4615 Drive Assembly Fertilizer Unit ...

Page 80: ...76 4615 Gear Box Fertilizer Unit ...

Page 82: ...78 4615 Box Bottom Assembly Fertilizer Unit ...

Page 84: ...80 4600 All Plant Feed Tubes Fertilizer Unit ...

Page 86: ...P O Box 1438 Dodge City Kansas 67801 620 227 7106 ...