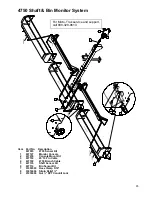

4750 Shaft & Bin Monitor System

Item

Part No.

Description

607093

4750 Sensor Kit

1

607127

Monitor Console

2

607218

Console Mount Kit

3

607150

45' 10 Pin Cable

4

607192

4750 Branch Cable

5

607135

Shaft Sensor Kit

6

607119

Bin Sensor Kit

7

01059500

Hose Clamp 5/16"

8

03412400

Strain Relief ½"

9

01076900

Nut ½" NPT Conduit Lock

For Micro-Trak service and support,

call 800-328-9613.

65

Summary of Contents for 4750 Drill

Page 1: ...P O Box 526 Spearville Kansas 67876 620 227 7106 4750 Drill OWNER S MANUAL 616698 2020 ...

Page 5: ...Safety RECOGNIZE SAFETY INFORMATION UNDERSTAND SIGNAL WORDS FOLLOW SAFETY INSTRUCTIONS 3 ...

Page 6: ...Safety OPERATE SAFELY AVOID TIP OVERS KEEP RIDERS OFF MACHINE 4 ...

Page 8: ...Safety USE A SAFETY CHAIN TRANSPORT SAFELY 6 ...

Page 9: ...Safety TOW LOADS SAFELY PRACTICE SAFE MAINTENANCE 7 ...

Page 20: ...Sprocket Locations 4750 Center Section 18 ...

Page 21: ...Sprocket Locations 4750 Wing Section 19 ...

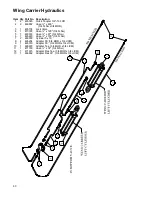

Page 33: ...4750 Wing Drive Left 31 ...

Page 35: ...4750 Wing Drive Right 33 ...

Page 37: ...4750 Gearbox Left 869693 35 ...

Page 39: ...4750 Gearbox Right 865105 37 ...

Page 42: ...This page left blank intentionally ...

Page 48: ...Fold Pull Bar 45 ...

Page 51: ...4750 Box 48 ...

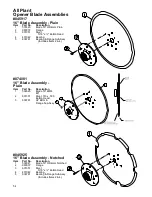

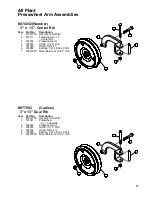

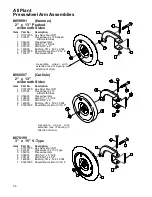

Page 55: ...All Plant Opener Assembly 52 ...

Page 62: ...This page left blank intentionally ...

Page 70: ...P O Box 526 Spearville Kansas 67876 620 227 7106 ...