7

Operating Procedures

Manual Operation

f. After clearance from module is obtained, or new site located, lower 3-point until front of

builder is firmly on ground.

g. Move to operator platform on builder.

h. Lower builder to ground by pushing axle lever and retracting axle cylinder until builder is

firmly on ground.

i. Pull axle lever until wheels just touch ground.

j. Push gate lever until gate is completely closed and properly latched.

k. Builder is now ready to build next module.

9. Preparing builder for transporting.

a. Move builder from module. Follow STEP 8 - Items a through e.

b. Make sure bridge is at front of builder and secured, so it can not move during

transportation.

c. Lower tamper to its lowest position, or until it rests on bridge pads.

d. Continue to pull on tamping lever which holds pressure on tamping cylinder. Pull on

unlocking lever to unlatch cylinder tower.

e. While holding unlocking lever open, push on tamping lever to lower cylinder tower.

f. Check rear gate. Make sure it is closed and latched properly.

g. Pull axle lever to raise builder to highest position.

h. Install transport brackets on both wheel cylinders. Transport brackets should be used

whenever transporting builder from field to field; or, over average distance on the road.

i. Disengage PTO on tractor.

j. Remove gear pump from PTO and place in transport pin on tongue and secure.

k. Raise 3-point to level builder and lock 3-point lever in tractor.

l. When moving builder be aware of short turning radius of tractor compared to tongue of

builder.

m. Be aware of width of builder, including hose rail on LH side as sitting in tractor seat.

n. Be aware of extended length of builder.

o. Be aware of moving builder through ditches or other uneven surfaces, due to the lower

clearance of builder from ground. Dragging can occur.

p. Slow moving vehicle sign is required in most states.

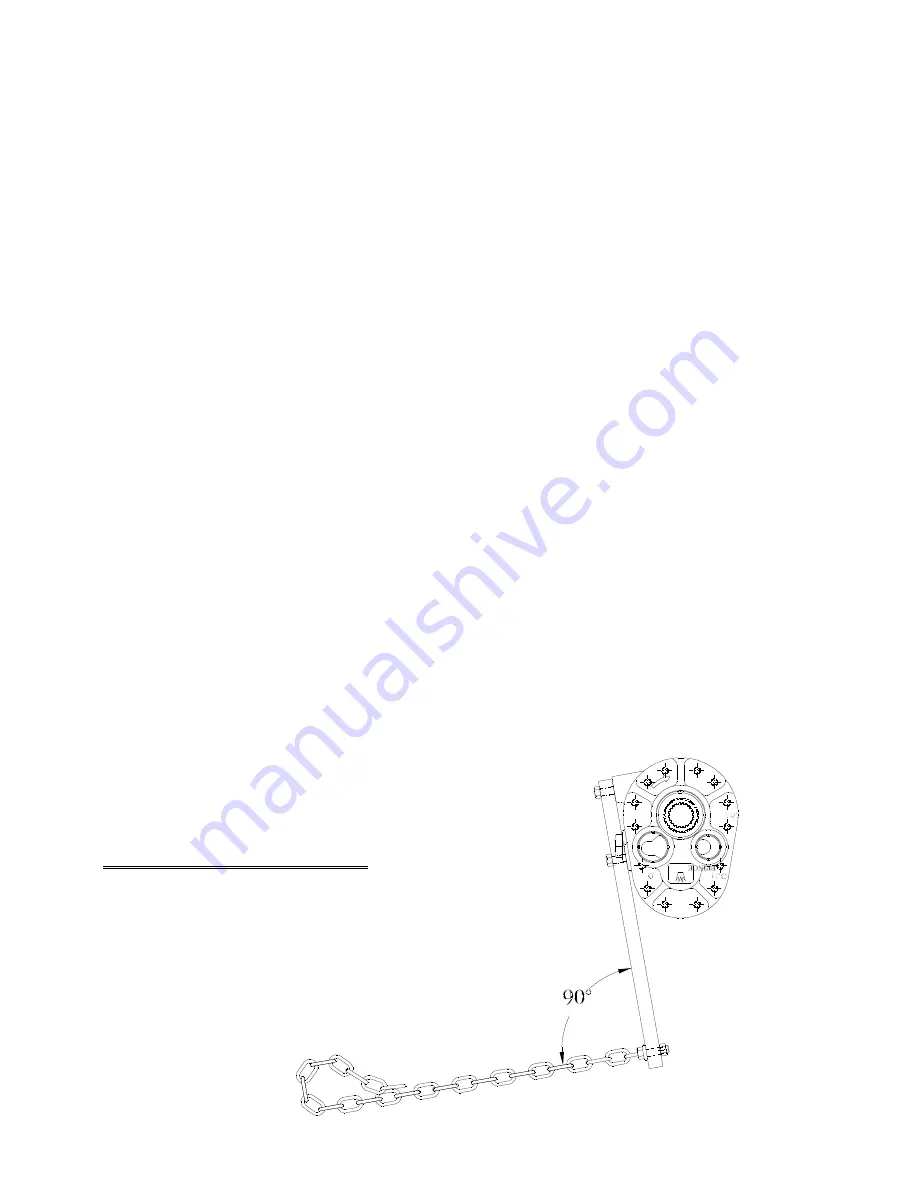

Hydraulic Pump

Recommended Mounting Procedure

Hydraulic pump mounts to 1000 RPM, 21 tooth

splined PTO shaft on tractor. PTO shaft should

extend into pump a minimum of 2½". The

torque arm should be chained to a rigid surface

with chain 90° to torque arm. The chain should

be perpendicular to the PTO shaft to avoid an

end thrust on the pump, and chain should be

safely wired or bolted together.

Summary of Contents for COTTON MODULE BUILDER

Page 1: ...COTTON MODULE BUILDER OWNER S MANUAL 00081000 02 08 ...

Page 28: ...26 Bridge Assembly Chain Drive ...

Page 30: ...28 Bridge Assembly Chainless ...

Page 34: ...32 Hydraulic Lines Chain Drive ...

Page 36: ...34 Hydraulic Lines Chainless ...

Page 42: ...P O Box 1438 Dodge City Kansas 67801 620 227 7106 ...