Cryo-con Model 24C

Basic Setup and Operation

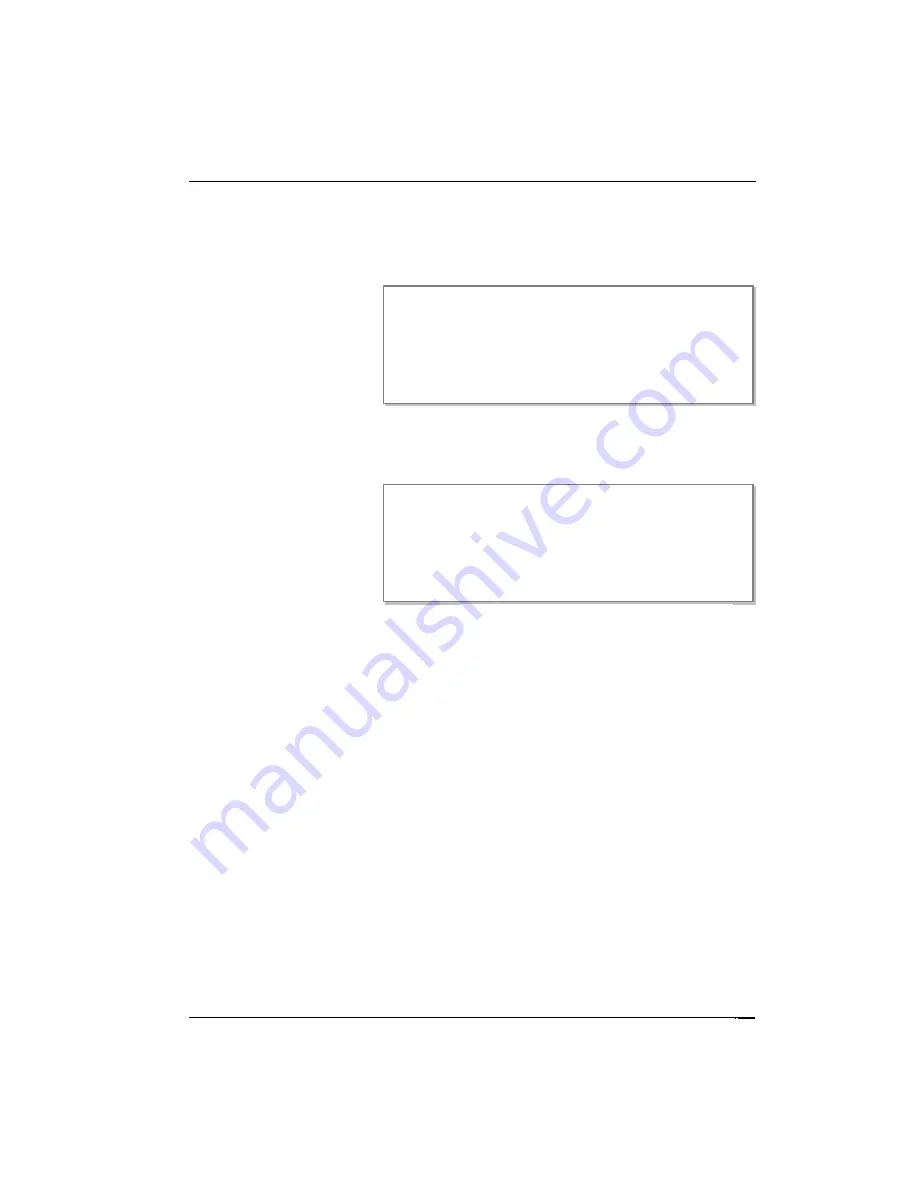

Now, you can begin ramping by changing the setpoint to the

end

of the ramp. The

display will indicate that a ramp is in-progress. In this example, the setpoint was

changed to 190 and the controller is ramping from 180.000. Notice that the loop

status area now indicates a ramp is in progress. The Ramp Pt: field shows where the

ramp should be and is

continuously updated until

the new setpoint is

attained. The input

temperature should track

the Ram Pt: field,

indicating that the ramp is

progressing as it should.

Ramping will continue until the setpoint is attained. Then, the loop status will return to

normal PID control and the

controller will maintain the

setpoint.

From here, each time you

change the setpoint, the

controller will ramp to the

new value and control

temperature there.

Summary

To perform a temperature ramp, proceed as follows:

1. Set the control loop P, I and D parameters to allow stable control at both ends

of the desired ramp. This is usually done by using ‘slow’ PID values (Low

values for P, high for I and zero for D).

2. Set the Ramp Rate in the Heater Configuration Menu. Set the setpoint to the

starting value for the ramp.

3. Press CONTROL. Now, the controller will begin temperature regulation at the

current setpoint.

4. Enter a new setpoint. The controller will enter ramping mode, and ramp to the

target setpoint at the specified rate. The word RMP will appear in the control

loop menu.

5. When the new setpoint is reached, ramping mode terminates and

temperature regulation begins at the new setpoint.

87

Loop 1A:Sample Holder

Set Pt:190.000K

Pgain: 5.0000

Igain: 120.00S

Dgain: 0.0000/S

Pman: 5.0000%

Type: RamP

Input: ChA

A: 190.000K

58% HI

--|

Range: HI

PID Table index: 1

Htr Load: 50

W

Next

Loop 1A:Sample Holder

Set Pt:190.000K

Pgain: 5.0000

Igain: 120.00S

Dgain: 0.0000/S

Pman: 5.0000%

Type: RamP

Input: ChA

A: 181.234K

Ramp HI

---|

Ramp Pt: 181.110

Range: HI

PID Table index: 1

Htr Load: 50

W

Next

Ramping to 190K

Ramp complete. Controlling at 190K