MERTIK MAXITROL REMOTE CONTROL SYSTEM

ADDITIONAL INSTRUCTIONS

THESE INSTRUCTIONS ARE FOR THE USE ON CRYSTAL FIRES REMOTE CONTROL RANGE OF

GAS FIRES

OPERATION

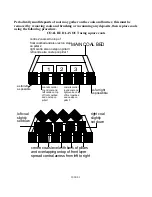

B

A

OFF POSITION

ON POSITION

FIGURE 1

IGNITION /PILOT

POSITION

LIGHTING PROCEDURE

1. TURN

KNOB

A

(FIGURE 1) SLIGHTLY LEFT TOWARDS THE IGNITION POSITION(SHOWN IN FIG 1 ABOVE)

UNTIL REACHING STOP,PRESS DOWN AND HOLD FOR FIVE SECONDS

(ONLY PILOT GAS FLOWS)

2. CONTINUE PRESSING DOWN KNOB

A

WHILE TURNING FURTHER LEFT TO ACTIVATE PIEZO,CONTINUE

TO HOLD DOWN FOR 10 SECONDS AFTER PILOT HAS BEEN LIT,IF PILOT DOES NOT LIGHT,STEPS 1 AND 2

CAN BE REPEATED IMMEDIATELY.

3. UPON LIGHTING,RELEASE KNOB

A

AND TURN FURTHER LEFT TO ON POSITION (SHOWN IN FIGURE 1

ABOVE)PILOT GAS FLOWS AND MAIN BURNER FLOWS IN ACCORDANCE TO THE FLAME

SETTING(KNOB

B

AS SHOWN IN FIG 1 ABOVE)

ADJUSTING THE FLAME SETTINGS

TO TURN THE FIRE ON AND/OR TO ADJUST THE

FLAME STTING, PRESS THE ON BUTTONS ON THE

REMOTE HANDSET.CONTINUE PRESSING UNTIL

DESIRED FLAME SETTING IS OBTAINED.PRESS

AND HOLD THE OFF BUTTON TO REVERSE THE

SETTING.THE RECEIVER IS EQUIPPED WITH A

BUILT IN DELAY, RECOGNIZABLE BY THE FLICKERING

LIGHT,TO FACILITATE FINE ADJUSTMENT OF THE FLAME

THE MOTORIZED VALVE IS EQUIPPED WITH A SLIP

CLUTCH ,ALLOWING MANUAL ADJUSTMENT OF MAIN

GAS BY TURNING KNOB B

OFF BUTTON

ON BUTTONS

TO PRESS THE ON BUTTON YOU MUST PRESS

THE 2 BUTTONS TOGETHER

ISSUE 1