MINI TRACKED DUMPER

16

GB

MAINTENANCE

Never use a “pressure washer” to

clean your unit. Water can penetrate

tight areas of the machine and its

transmission case and cause damage

to spindles, gears, bearings, or the

engine. The use of pressure washers

will result in shortened life and

reduce serviceability.

S u d d e n s t o p p i n g a t a h i g h

speed under a heavy load is not

recommended. Engine damage may

result.

Do not move the choke control to

CLOSE to stop the engine. Backfire

or engine damage may occur.

1.

1.

1.

2.

2.

3.

3.

4.

5.

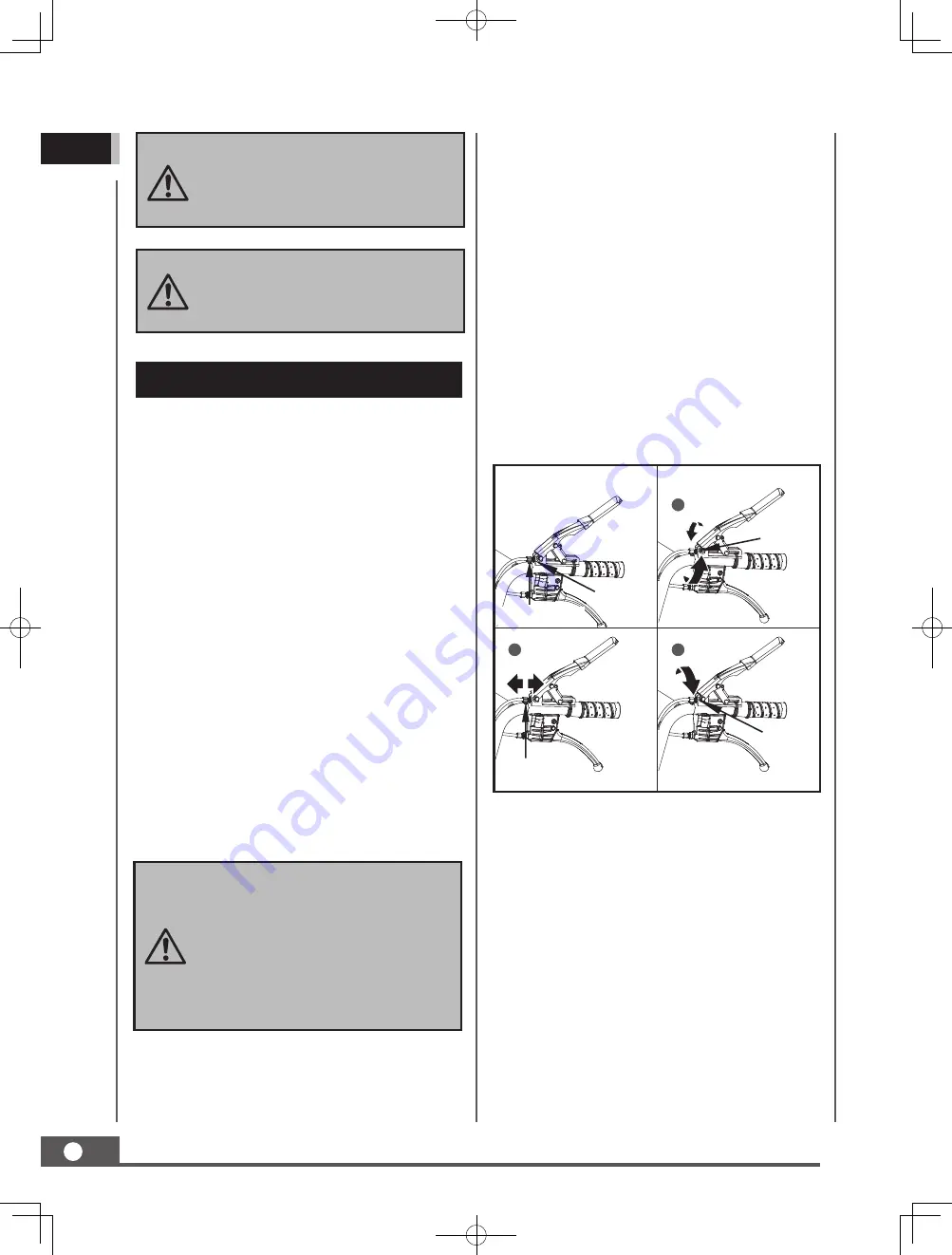

Adjusting Clutch

When the clutch begins to show wear, the

handle reach will become wider, making it

more difficult to reach. Follow these steps

to return the clutch lever back to its original

position.

Maintaining your mini tracked dumper will

ensure long life to the machine and its

components.

Preventive Maintenance

Jam Nut

Adjustment Nut

Adjustment Nut

Jam Nut

Jam Nut

1

2

3

Adjusting Steering

If steering becomes difficult to engage follow

these steps to adjust the cable tension.

Turn off the engine and disengage all

command levers. The engine must be cool.

Keep the engine’s throttle lever in its SLOW

position and remove the spark plug wire

from the spark plug and secure.

Inspect the general condition of the power

trackbarrow. Check for loose screws,

misalignment or binding of moving parts,

cracked or broken parts, and any other

condition that may affect its safe operation.

Use a soft brush, vacuum or compressed

air to remove all contaminants from the

machine. Then use high quality light oil to

lubricate all moving parts.

Check the spark plug wire regularly for

signs of wear, and replace when needed.

Loosen the jam nut by turning it counter

clockwise with 10mm wrench.

Tighten or loosen the cable by turning the

cable adjustment nut clockwise or counter

clockwise with 10mm wrench until you

have reached your required tightness.

Once tightness is set, return the jam nut

against the handle to hold the cable in

place.

Loosen the jam nut by turning it counter

clockwise with 10mm wrench.

2.

3.

Tighten or loosen the cable by turning the

cable adjustment nut clockwise or counter

clockwise with 10mm wrench until you

have reached your required tightness.

Once tightness is set, return the jam nut

against the handle to hold the cable in place.