Operation

Page 20

FA 550 V1.00

12.1

Initialization

12.2 Main menu

P age-No.

S W V ersion

Mo dbus ID

Switching to pages 2-3 or back by pressing key

„

“

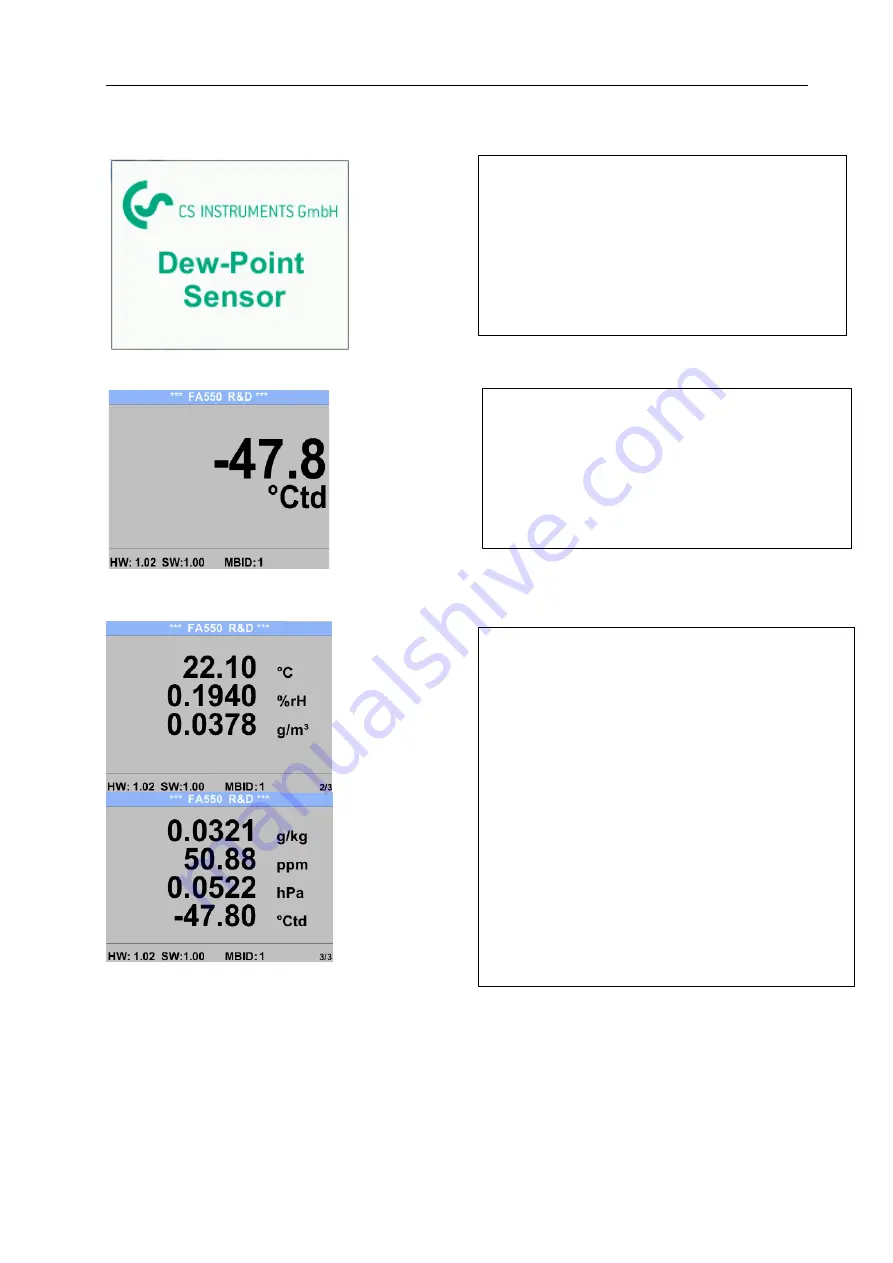

After switching on the FA 550, the initialized screen

is displayed followed by the main menu.

Page 1

Display value is the pressure dew point, here in

°Ctd. (When measured under pressure)

The pressure dew point is always based on the

pressure in the compressed air pipe.

Page 2

Value 1: Temperature in °C

Value 2: relative humidity in %

Value 3: vapour humidity in g/m³

Page 3

Value 1:Absolute humidity in g/kg

**

Value 2 Parts per Million

**

Value 3:Atmospheric dew point (when the

reference pressure is set to atmospheric

pressure 1013,25 hPa) or reference dew

point based on the reference pressure

setting.

**

For the calculation, the input of the system

pressure is mandatory. For entering see

chapter, see 8.3.2.