8

V5-02-2010

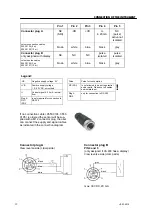

The following table shows the equalising sections necessary in relation to existing ob-

structions:

INSTALLATION DESCRIPTION

Flow obstruction

in front of

the measuring section

Minimum length

inlet (L1)

Minimum length

outlet (L2)

Slight curve

(bend < 90°)

12 x D

5 x D

Reduction

(pipe narrows towards the meas. section)

15 x D

5 x D

Expansion

(pipe expands towards the meas. section)

15 x D

5 x D

90° bend

or T piece

15 x D

5 x D

2 bends á 90°

on one level

20 x D

5 x D

2 bends á 90°

3-dimensional change of direction

35 x D

5 x D

Shut-off valve

45 x D

5 x D

Table of inlet and outlet sections

The respective minimum values required are indicated here.

If it is not possible to observe the stipulated equalising sections, considerable deviations in

measuring results must be expected.

Sensor installation

Hint for the installation with ball valve:

Ball valve R 1/2“, DN 15

Passage ball valve minimum Ø15 mm

Consider the flow direction which should match with the

arrows at the connector head.

Measure from here to the tube center

Read the insertion position here

The sensor head must be placed in the centre of the pipe. Therefore the probe shaft has a

scale. To determine the right position measure the length from the marked position to the

centre of the tube. The probe then will be inserted up to this measure and then tightened up.

mm

Summary of Contents for VA 400

Page 27: ...27 V5 02 2010 DECLARATION OF CONFORMITY...

Page 28: ...28 V5 02 2010 DECLARATION OF CONFORMITY...

Page 29: ...29 V5 02 2010 NOTES...

Page 30: ...30 V5 02 2010 NOTES...

Page 31: ...31 V5 02 2010 NOTES...