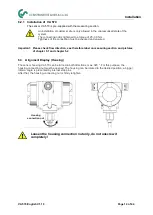

Operation

VA 570 English V1.19

Page 21 of 44

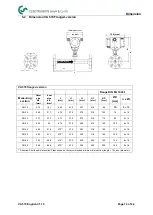

8.1

Main menu (Home)

8.1.1 Intialization

VA 570

8.2

Main menu

HW Version

Page-No.

Gas /

Status Info

SW Version

Modbus ID

*** VA 550 ***

Switching to pages 2-4 or back by pressing key

„

>

“

*** VA 550 ***

391.23

391

1 minutes

410,34

1 minute

91,32

82.46

AV-Time ( Period for average value calculation) could be changed under

Sensor Setup.-Advanced

– AV-

Time

After switching on the VA 570, the initialized

screen is displayed followed by the main

menu.

Flow Sensor