91

ADJUSTING OR CHECKING FURNACE INPUT

The maximum gas supply pressure to the furnace should

be 10.5" w.c. for natural gas and 13.0" w.c. for L.P. The

minimum gas supply pressure for purposes of input adjust-

ment to the furnace should be 5" w.c. for natural gas and

11.0" w.c. for L.P.

A calibrated manometer is required for accurate gas pres-

sure readings.

The manifold pressure should be set at 3.5" w.c. for natural

gas and 10.0" w.c. for L.P. Only small variations in the gas

flow should be made by means of the pressure regulator

adjustment. In no case should the final manifold pressure

vary more than plus or minus 0.3" w.c. from the above-

specified pressures. To adjust the pressure regulator, re-

move the regulator cap and turn the adjustment screw

clockwise to increase pressure or counterclockwise to de-

crease pressure. Then replace the regulator cap securely.

Any necessary major changes in the gas flow rate should

be made by changing the size of the burner orifices.

To change orifice spuds, shut off the manual gas valve and

remove the gas manifold. On LP gas furnaces, the LP gas

supply pressure must be set between 11" and 13" w.c. by

means of the tank or branch supply regulators. The fur-

nace manifold pressure should be set at 10" w.c. at the gas

control valve. For elevations up to 2,000 feet, rating plate

input ratings apply. For high altitudes (elevations over

2,000 ft.), see conversion kit index for derating and orifice

spud sizes.

Checking furnace input is important to prevent over firing

beyond its design-rated input. NEVER SET INPUT ABOVE

THAT SHOWN ON THE RATING PLATE. Use the follow-

ing table or formula to determine input rate. Start the fur-

nace and measure the time required to burn one cubic foot

of gas. Prior to checking the furnace input, make certain

that all other gas appliances are shut off, with the excep-

tion of pilot burners. Time the meter with only the furnace

in operation.

TABLE 17

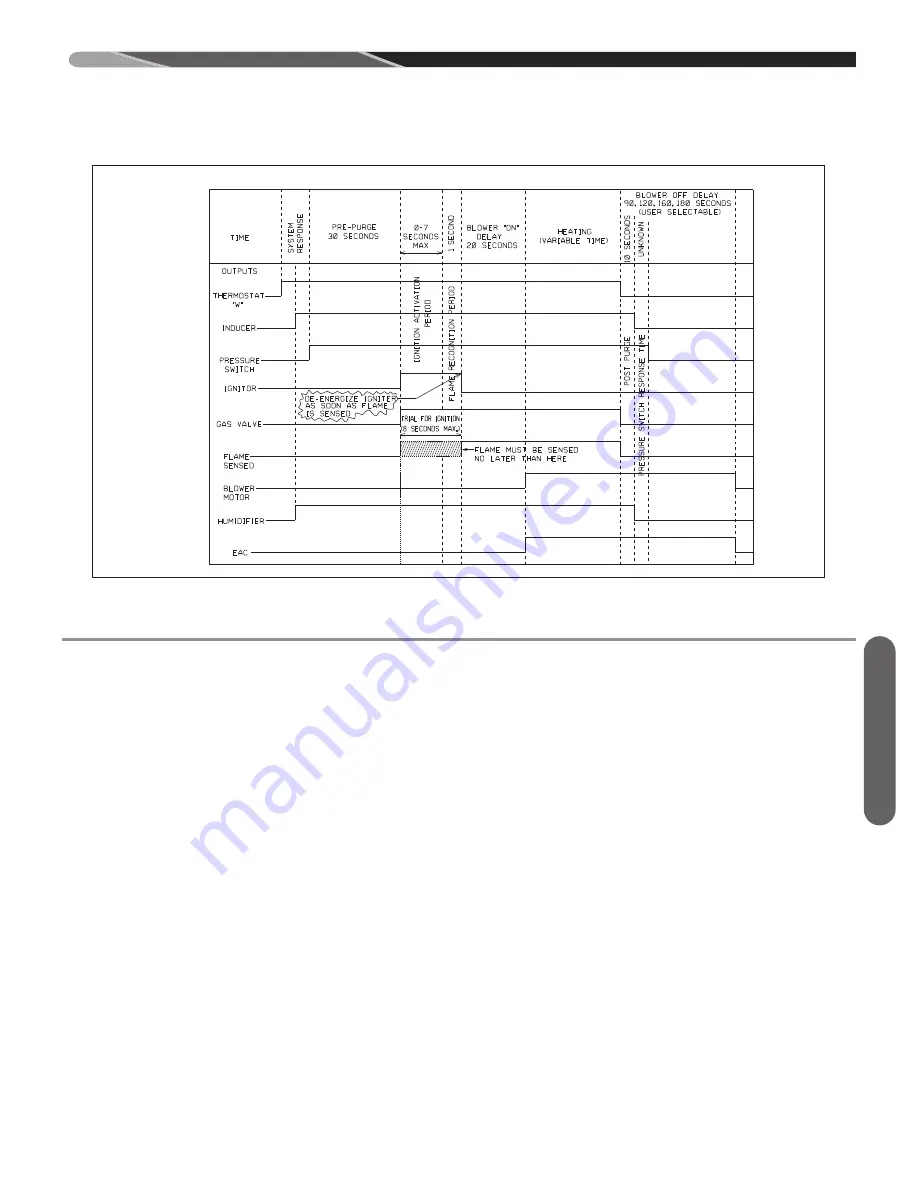

TIMING DIAGRAM

ST-A1194-27-X0

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OPEN

OFF

OFF

CLOSED

OPEN

ON

ON

ON

ON

ON

ON

OFF

ON

TIMING DIAGRAM, FIELD SELECTIONS &

ADJUSTMENTS

Field Selections

Summary of Contents for 92MSP SERIES

Page 34: ...34 Field Conversions ...

Page 35: ...35 Field Conversions ...

Page 36: ...36 Field Conversions ...

Page 37: ...37 Field Conversions ...

Page 38: ...Field Conversions 38 ...

Page 99: ...99 ...

Page 100: ...100 CM 0716 ...