26

| English

2 610 A15 112 • 12.8.09

Working without Automatic Levelling (“OFF”)

When the automatic levelling is switched off, the lev-

elling of the axes is no longer monitored; the shock-

warning function is also switched off.

f

Position changes of the measuring tool are

not detected when the automatic levelling is

switched off.

As soon as a grade is set for an axis in horizontal posi-

tion, the automatic levelling is automatically switched

off regardless of the selected setting.

When the automatic levelling is switched off, the

measuring tool can be set up in any inclined position.

With the gradient plate (accessory), the measuring

tool can also be exactly inclined alongside an axis at

an angle larger than 10 % when in the horizontal posi-

tion.

Grade Setting in the Horizontal

Position

When the measuring tool is in the horizontal position,

grades to

±

10 % can be exactly set for both axes inde-

pendent from each other.

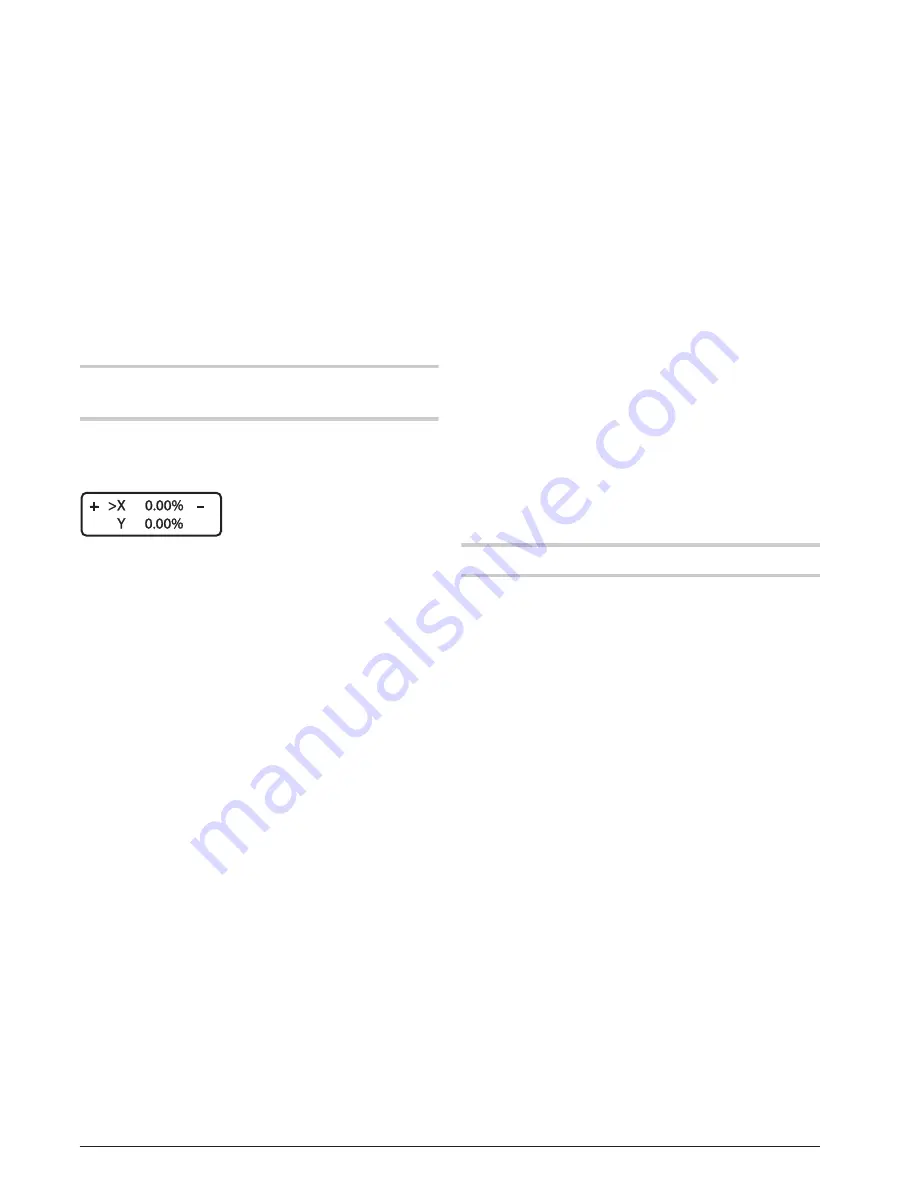

After switching on in the hori-

zontal position, the menu for

grade adjustment appears on

the display. To call up the

grade menu again, e.g. after changing the operating

mode, press the function-mode button

7

until

“SELECT/GRADE”

is indicated on the display. Then

press the left selection button

8

.

By briefly pressing the function-mode button

7

, you

can select the axis for which the grade is to be set.

The selected axis is marked with

“>”

. Set the desired

grade value with selection button

8

above

“+”

or

selection button

4

above

“–”

. To exit the grade menu,

press function-mode button

7

for 5 seconds.

The grade setting is stored when switching off the

measuring tool. To horizontally align the rotational

plane, set both grade values to 0.00 %.

The maximal grade of 10 % can only be reached when

the measuring tool is exactly horizontal. When

inclined, the maximal grade angle is reduced by the

inclined angle. When the set grade angle cannot be

reached,

“ERROR/GD TOO STEEP”

is indicated on

the display.

In this case, switch the measuring tool off, re-align it

and switch the measuring tool on again. If the measur-

ing tool is not re-positioned, it is automatically

switched off after 2 minutes.

To achieve the greatest possible accuracy for grading

work, the following points must be observed:

– Set up the measuring tool as level as possible

before switching on or setting a grade.

– The automatic levelling is switched off automati-

cally when the axes are inclined.

– When only one axis is inclined, the shock-warning

function for the second axis can be switched on.

The shock-warning function is deactivated for

approx. 30 seconds each time after changing the

grade value. When the shock-warning function is

actuated from position changes, the rotational plane

is exactly inclined again according to the stored

value after the levelling.

– When both axes are inclined, the shock-warning

function is automatically deactivated. Position

changes of the measuring tool are not detected.

– After position changes of the measuring tool when

both axes are inclined or when the shock-warning

function is shut off, switch the measuring tool off

and then on again. After switching on, the rota-

tional plane firstly levels out horizontal before

being exactly inclined with the stored values.

Grades in only one axis should be set at the Y-axis, as

the measuring tool can be easier aligned with the

alignment aids

12

alongside this axis.

Accuracy Check of the Measuring Tool

Influences on Accuracy

The ambient temperature has the greatest influence.

Especially temperature differences occurring from the

ground upward can divert the laser beam.

The deviations play a role in excess of approx. 20 m

measuring distance and can easily reach two to four

times the deviation at 100 m.

Because the largest difference in temperature layers

is close to the ground, the measuring tool should

always be mounted on a tripod when measuring dis-

tances exceeding 20 m. If possible, also set up the

measuring tool in the centre of the work area.

Apart from exterior influences, device-specific influ-

ences (such as heavy impact or falling down) can lead

to deviations. Therefore, check the accuracy of the

measuring tool each time before starting your work.

To check the accuracy, select rotational operation

and, if required, use the laser receiver to mark the cen-

tre of the rotating laser beam.

Should the measuring tool exceed the maximum devi-

ation during one of the tests, please have it repaired

by a Bosch after-sales service.

OBJ_BUCH-971-001.book Page 26 Wednesday, August 12, 2009 8:46 AM

Summary of Contents for AL-Series

Page 2: ...2 2 610 A15 112 12 8 09 6 5 3 4 3 8 7 2 2 1 9 12 13 16 17 18 14 15 11 10 13 ALGR...

Page 3: ...3 2 610 A15 112 12 8 09 19 21 22 23 24 20 25 B A...

Page 4: ...4 2 610 A15 112 12 8 09 28 27 26 29 30 31 32 33 34 35 37 36 38 39 40 RC400X...

Page 155: ...E 155 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f UV f f f f f f f CST berger 23 f 23...

Page 158: ...158 E 2 610 A15 112 12 8 09 f f f 163 24 f f ON OFF 6 9 1 5 162 0 00 30 s 5 161 60 s ON OFF 6...

Page 163: ...E 163 2 610 A15 112 12 8 09 30 s 12 20 m 100 m 20 m 20 m Service Bosch 30 m 30 m 0 00 I 30 m...

Page 165: ...E 165 2 610 A15 112 12 8 09 5 8 13 13 5 8 B 24 5 8 13 24 24 15 cm 23 23 23 1 9...

Page 240: ...240 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f f f f f f f f CST berger 23 f 23...

Page 243: ...243 2 610 A15 112 12 8 09 f f f 248 24 f f 6 9 1 5 247 0 00 30 5 245 60 6...

Page 255: ...255 2 610 A15 112 12 8 09 Bosch 10 oe e e e oe e e e 251 252...

Page 256: ...256 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f f f f f f f f CST berger 23 f 23...

Page 270: ...270 2 610 A15 112 12 8 09 Bosch 10 C a a c ep i i i C a a c ep i i i 267 267...

Page 285: ...285 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f f f f f f f f CST berger 23 f 23...

Page 294: ...294 2 610 A15 112 12 8 09 22 600 min 1 25 3 25 297 5 8 13 13 24 5 8 13 24 24 15 cm 23 23 23...