32

| English

2 610 A15 112 • 12.8.09

Operation

Initial Operation

f

Protect the remote control against moisture

and direct sunlight.

f

Do not subject the remote control to extreme

temperatures or variations in temperature.

As an example, do not leave it in vehicles for longer

periods. In case of large variations in temperature,

allow the remote control to adjust to the ambient

temperature before putting it into operation.

The remote control remains ready for operation as

long as batteries with sufficient voltage are inserted.

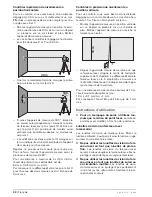

Set up the rotational laser in such a manner that the

signals of the remote control directly reach one of the

receiption lenses on the rotational laser (for this, see

the operating instructions of the rotational laser).

When the remote control cannot be pointed directly

against a receiption lens, the working range is

reduced. By reflecting the signal (e.g. against walls),

the working range can be improved, even for indirect

signals.

After pressing a button on the remote control, the illu-

minated operation indicator

27

indicates that a signal

was sent out. When the signal has reached the rota-

tional laser level, the rotational laser level emits an

audio signal for confirmation.

Switching the rotational laser on/off with the remote

control is not possible.

Operating Modes

The automatic levelling and the shock-warning func-

tion can not be switched on and off with the remote

control.

For detailed information of the rotational laser level

functions, see the operating instructions of the rota-

tional laser level (see “Rotational Laser Level”, from

page 20 on).

Rotational Operation

Press function-mode button

38

and then press the

“UP” 29

or

“DOWN” 36

button to start rotational

operation.

Press the

“UP ”

button

29

to increase the rotational

speed indicated on the display of the rotational laser

level or the

“DOWN”

button

36

to decrease the rota-

tional speed.

Line Operation with Standard Line

Press function-mode button

38

and then press the

“LONG” 40

or

“SHORT”

button

30

to start line oper-

ation with a standard line.

Press the

“LONG”

button

40

to increase the aperture

angle of the laser line or the

“SHORT”

button

30

to

decrease the aperture angle.

Press the

“CCW”

button

37

to rotate the laser line

counterclockwise within the the rotational plane or the

“CW”

button

32

to rotate the laser line clockwise.

Line Operation with Programmable Line

Press function-mode button

38

and then press the

“P TO P”

button

28

to start line operation with a pro-

grammable line.

Rotate the laser point at the desired left end point of

the laser line by pressing the

“CCW”

button

37

or the

“CW”

button

32

. Press the

“P TO P”

button

28

to

store the left end point.

Then rotate the laser point at the desired right end

point of the laser line by pressing the

“CCW”

button

37

or the

“CW”

button

32

. Press the

“P TO P”

button

28

to store the right end point.

The measuring tool now indicates a laser line between

both positioned points.

Point Operation

Press function-mode button

38

and then press the

“CCW”

button

37

or the

“CW”

button

32

to start

point operation.

Rotate the laser point to the desired position within

the rotational plane by pressing the

“CCW”

button

37

or the

“CW”

button

32

.

Grade Setting in the Horizontal Position

Press function-mode button

38

and then press the

“LEFT” 39

or

“RIGHT” 31

direction and grade but-

ton to access the grade menu.

Press the

“LEFT” 39

or

“RIGHT” 31

direction and

grade button to change the grade of the X-axis. Press

the

“UP” 29

or

“DOWN” 36

grade button to change

the grade of the Y-axis.

Aligning the Rotational Plane in the Vertical

Position

When the measuring tool is in the vertical position, the

rotational plane can be rotated around the Y-axis by

pressing the

“LEFT” 39

or

“RIGHT” 31

direction and

grade button (depends on whether the measuring tool

is in rotation, line or point operation).

OBJ_BUCH-971-001.book Page 32 Wednesday, August 12, 2009 8:46 AM

Summary of Contents for AL-Series

Page 2: ...2 2 610 A15 112 12 8 09 6 5 3 4 3 8 7 2 2 1 9 12 13 16 17 18 14 15 11 10 13 ALGR...

Page 3: ...3 2 610 A15 112 12 8 09 19 21 22 23 24 20 25 B A...

Page 4: ...4 2 610 A15 112 12 8 09 28 27 26 29 30 31 32 33 34 35 37 36 38 39 40 RC400X...

Page 155: ...E 155 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f UV f f f f f f f CST berger 23 f 23...

Page 158: ...158 E 2 610 A15 112 12 8 09 f f f 163 24 f f ON OFF 6 9 1 5 162 0 00 30 s 5 161 60 s ON OFF 6...

Page 163: ...E 163 2 610 A15 112 12 8 09 30 s 12 20 m 100 m 20 m 20 m Service Bosch 30 m 30 m 0 00 I 30 m...

Page 165: ...E 165 2 610 A15 112 12 8 09 5 8 13 13 5 8 B 24 5 8 13 24 24 15 cm 23 23 23 1 9...

Page 240: ...240 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f f f f f f f f CST berger 23 f 23...

Page 243: ...243 2 610 A15 112 12 8 09 f f f 248 24 f f 6 9 1 5 247 0 00 30 5 245 60 6...

Page 255: ...255 2 610 A15 112 12 8 09 Bosch 10 oe e e e oe e e e 251 252...

Page 256: ...256 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f f f f f f f f CST berger 23 f 23...

Page 270: ...270 2 610 A15 112 12 8 09 Bosch 10 C a a c ep i i i C a a c ep i i i 267 267...

Page 285: ...285 2 610 A15 112 12 8 09 f f 10 f f 2 IEC 60825 1 f f f f f f f f f CST berger 23 f 23...

Page 294: ...294 2 610 A15 112 12 8 09 22 600 min 1 25 3 25 297 5 8 13 13 24 5 8 13 24 24 15 cm 23 23 23...