z

According to the design of our installation manual, Final customers could adopt the screw

installation method to make the frame supporting.

z

Put the modules on the frame and put on the screws and then combine them firmly after put on

all the gaskets. The module frame is made of anodized aluminum, and therefore corrosion can

occur if the module is subject to a salt-water environment with contact to a rack of another type

of metal.(Electrolysis Corrosion) if required. PVC or stainless steel washers can be placed

between the solar module frame and support structure to prevent this corrosion.

z

Module support structures that are to be used to support modules should be wind rated and

approved for use by the appropriate local and civil codes prior to installation.

Do not use module

near equipment or in locations where flammable gases can be generated or collected.

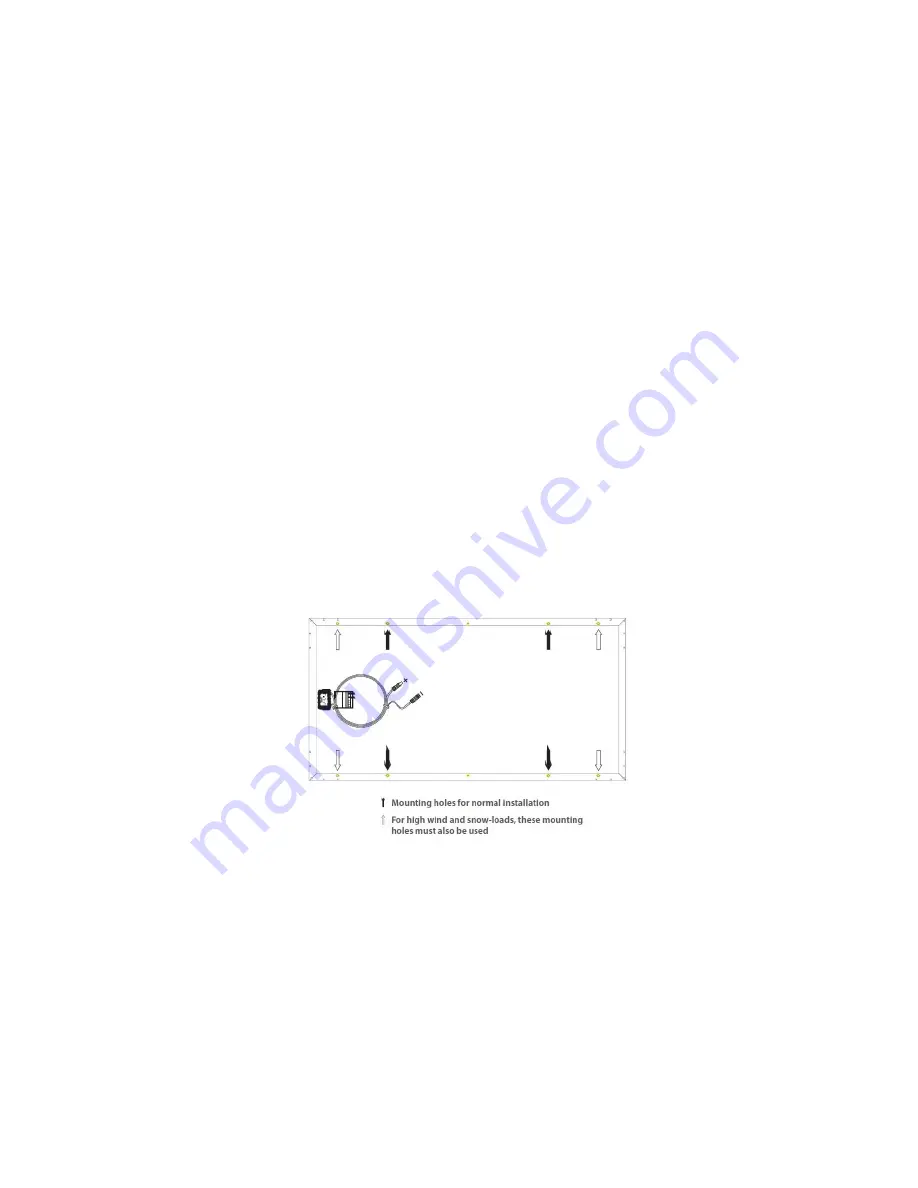

⑵

Selecting the proper support frame

z

Always observe the instructions and safety precautions included with the support frames to be

used with the modules.

z

Do not attempt to drill holes in the glass surface or additional mounting holes in the frame. To do

so will void the warranty.

z

Modules must be securely attached to the mounting structure using four mounting holes for

normal installation. If additional wind or snowloads are anticipated for this installation, additional

mounting holes are also used. The details please see the above drawing. Load calculations are left

to the system designers or installers.

z

The support module mounting structure must be made of durable, corrosion-resistant and

UV-resistant material.

z

Select the height of the mounting system to prevent the lowest edge of the module from being

covered by snow for a long time in winter in areas that experience heavy snowfalls. In addition,