12

CTC 380 S

General information

2.6

Connection to chimney

Existing regulations for the design of the chimney must be taken into

consideration. An optimal utilization of the flue gases and with that an

energy-saving operation, requires hereby a mostly optimized adaption

between boiler and burner.

The most important conditions are the following:

• Good thermal insulation in order to as much as possible avoid

temperature losses from the connection between the boiler and

chimney.

• Accurate sealing of the flue gas connections

• Smooth surfaces of the combustion chamber to avoid turbulence.

• Heat-shock resistance as well as water- and steamtight.

According to regulations:

• The boiler must be connected to the chimney with the shortest feasible

flue duct at an angle of 30-45°.

• The flue duct must not be fully inserted through the chimney wall.

• If flue ducts with a cross-sectional dimension which deviate from the

dimension of the flue gas outlet would be used, the connection must

be cone-shaped. Cone angle of maximum 7,5°.

• By the construction of the flue duct between boiler and chimney must

feasible actions be taken to secure that no condensate can flow back

to the boiler (condensate trap).

2.7

Flue gas temperatures

When a new boiler is being connected to an old chimney, the chimney is

often not dimensioned to the new high efficiency of the boiler, which may

easily result in condensation in the chimney depending on lower flue gas

temperatures. In order to ventilate the chimney with warmer boiler room air, a

draught interrupter can be mounted.

All boiler-sizes of the CTC 380 Ecoswiss serie has for the current output-size

design related operational flue gas temperatures. For flue gas temperature

data, see Technical information.

2.8

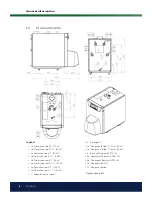

Hydraulic connection boiler

The dimensioning and plumbing of the system shall be accomplished

according to the measurements in the part Technical information.

2.9

Safety valve boiler

In a closed system, an approved safety valve according to existing

regulations must be mounted.

The max. Operation pressure of the boiler is 3 bars. The connection

pipebetween boiler and safety valve must be constructed in such way

that no pressure increase is possible. The safety valve drain pipe must be

uncovered and visible. Possible exhausting high-temperature hot water must

without danger be removed (Caution! Risk of scalding)

Summary of Contents for 380 S 18

Page 2: ......

Page 42: ...42 CTC 380 S General information ...