52

CTC EcoFlex

Installation

12. First start

Before first start

1.

Check that the flue gas by-pass valve has not been displaced during

transport/installation.

2.

Check that the boiler and system are full of water and bled.

3.

Check that all connectors are tight and that the connection to the

chimney has bee correctly carried out.

4.

Check that all sensors and heating circuit pump are connected to the

power supply.

5.

Set the pellet burner switch to position ”0”.

First start, boiler (burner not started)

1.

Switch on the power using the operation switch. The display comes

on

2.

The heating boiler now asks whether the system and the boiler have

been filled with water. Confirm using ”OK”.

First start, pellet burner

1.

Make sure that the external feed system (the external auger) is filled

with pellets, see the section ”Start up from shut off mode”.

2.

To start the burner, set the pellet burner switch in position ”1”. Check

that the burner starts as described in the section ”Start up from shut

off mode”The pellet burner is factory set to power: Full = 15 kW, Part

= 9 kW.

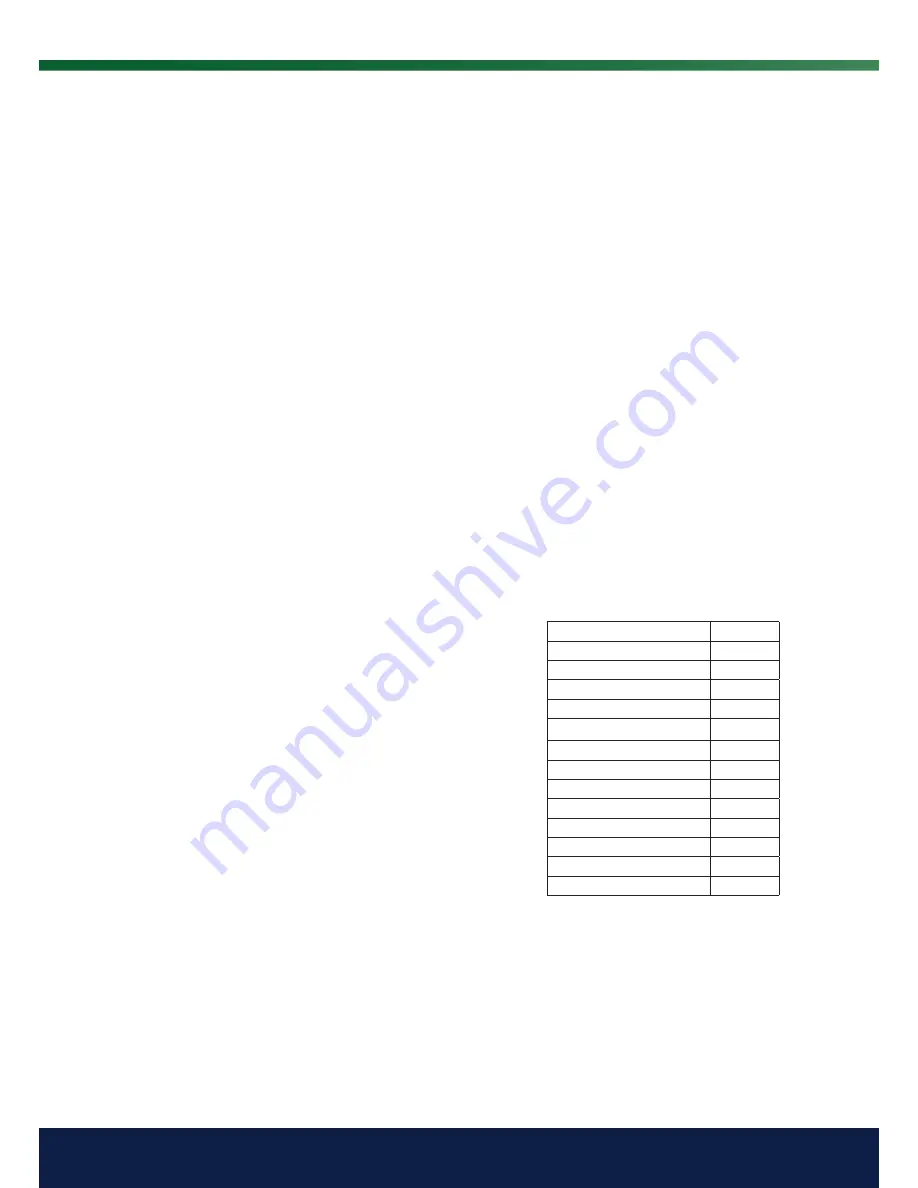

First start, set pellet size (diameter)

(Installer/Settings/Setting pellet)

The pellet burner is from factory pre-set for operation of pellet sizes with

a diameter of 8 mm. By the operation of pellet with a diameter of 6 mm,

perform the necessary settings according to the chart below. The settings

are made according to the description in the section ”Menu Setting pellet”

Flue gas temperatures:

Check and adjust the flue gas temperature, see the section

” Flue gas temperature/condensation risk”.

System settings

The installation engineer should set the settings on the boiler when

installing. Settings set in Menu: Installer / Settings /…In addition see the

section ”The menu system.”

When the system is warm, check that all connections are tight, that the

varios systems are bled, that the heat comes out of the system and that

hot water comes out of the tapping point.

Go through the settings with the user.

Diameter ø Pellet (mm)

6

Setting pellet

Level sensor, %

*

Flame detector, %

*

Burner type, kW

15

Power full auger, %

50

Power full fan, %

*

Power part auger, %

30

Power part fan, %

*

Power min auger, %

*

Power min fan, %

*

Holding min

*

Auger Feeder

*

Sequenz code

*

*) Settings you should not change

Summary of Contents for ecoflex

Page 2: ......

Page 53: ...53 CTC EcoFlex Installation 13 Electric diagram 230V 1N ...

Page 54: ...54 CTC EcoFlex Installation 14 Electric diagram 400V 3N ...

Page 56: ...56 CTC EcoFlex Installation Declaration of Conformity ...

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ...Enertech AB P O Box 309 SE 341 26 Ljungby Sweden www ctc se www ctc heating com ...