28

ADDING TRANSMISSION OIL

CAUTION

Never overfill the transmission case. Damage

may result if the oil level in the transmission

case is below the “ADD” mark or over the

“FULL” mark of the dipstick. For best results, fill

to the “FULL” mark on the dipstick as opposed

to adding a given quantity of oil. Always check

the level on the dipstick before adding more oil.

Refer to the

LUBRICATION TABLE

for information

regarding the proper type of oil to add to the

transmission case.

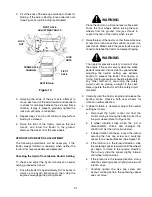

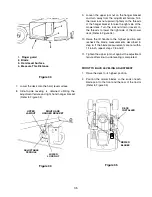

1.

Place the tractor on a level surface and engage the

brake pedal lock. Stop the tractor engine and

remove the ignition key.

2.

Clean the area around the oil fill plug/dipstick to

prevent debris from entering the transmission

case.

3.

Remove the oil fill plug/dipstick from the oil fill port

and SLOWLY pour oil into the oil fill port. Fill the

transmission case until the oil level reaches the

“FULL” mark on the dipstick (Refer to Figure 22).

4.

Reinstall the oil fill plug/dipstick securely into the

oil fill port.

CAUTION

The oil fill plug/dipstick MUST BE INSTALLED

SECURELY INTO THE FILL PORT AT ALL

TIMES WHEN THE ENGINE IS OPERATING.

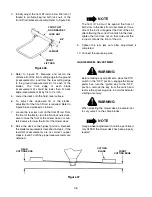

HYDROSTATIC DRIVE OIL FILTER

CAUTION

Never overfill the transmission case. Damage

may result if the oil level in the transmission

case is below the “ADD” mark or over the

“FULL” mark of the dipstick. For best results, fill

to the “FULL” mark on the dipstick as opposed

to adding a given quantity of oil. Always check

the level on the dipstick before adding more oil.

Refer to the

MAINTENANCE CHART

for the

frequency of replacement for the hydro transmission oil

filter. The filter can be obtained through your

Cub

Cadet

dealer under the part number 923-3014.

Refer to the

LUBRICATION TABLE

for information

regarding the oil capacity and the proper type of oil to

pour into the transmission case.

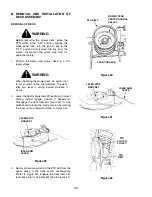

1.

Place the tractor on a level surface and engage the

brake pedal lock. Stop the tractor engine and

remove the ignition key.

2.

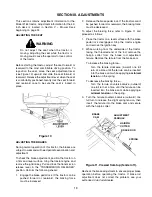

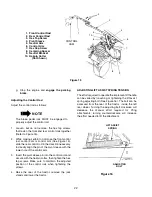

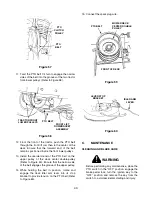

Clean the area around the transmission drain plug

to prevent debris from entering the transmission

case. Remove the drain plug and allow the

transmission oil to drain into a clean container

having a capacity of more than 7 quarts. Reinstall

the drain plug (Refer to Figure 23).

Figure 23

CAUTION

If the transmission oil is to be re-used, cover the

container holding the drained oil to prevent

contamination. Contaminated transmission oil

can damage the hydro transmission.

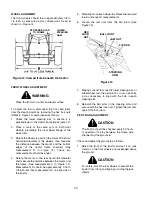

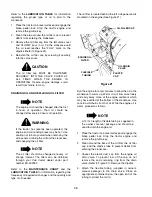

3.

Clean around the base of the transmission oil filter

and remove the filter by turning it counterclockwise

(Refer to Figure 24).

Figure 24

TRANSMISSION

DRAIN PLUG

TRANSMISSION

OIL FILTER