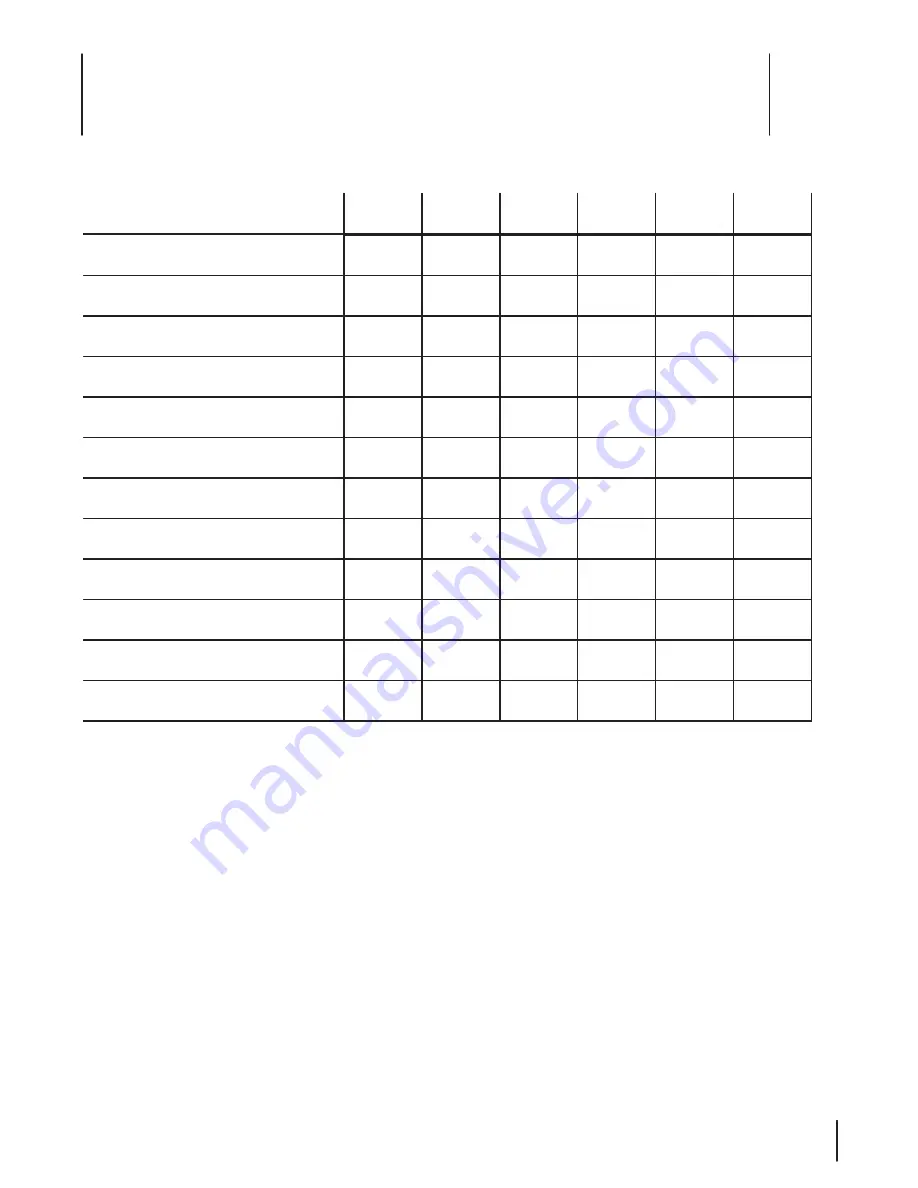

Maintenance Chart

8

21

* Change at the first 50 hours, then again at 500 hours.

† Lubricate after each use if unit is run through water deeper than axle.

†† Drain after a deep water crossing (More than 12”).

Maintenance Schedule

Before Each

Use

First 10

Hours

Every 50

Hours

Every 100

Hrs. or Yearly

Every 500

Hrs. or 2 Yrs.

Service

Dates

Check Transfer Case Oil

P

Change Transfer Case Oil*

P

Tighten Wheel Bolts

P

Check Engine Coolant Level

P

Change Engine Coolant

P

Inspect Cooling System Hoses

P

Lubricate Rear Knuckles †

P

Inspect OPS

P

Inspect Front and Rear Shocks

P

Inspect Ball Joints

P

Inspect CV Boots

P

Drain CVT Cover ††

P

P

NOTE:

For information regarding engine service, see the separate Engine Owner’s Manual included with your unit.