6

S

ection

2 — A

SSembly

& S

et

-U

p

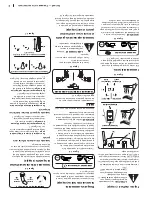

Drift Cutters

(If Equipped)

The drift cutters are mounted inverted at the

factory for shipping purposes.

Standard

1.

Remove two screws (a) and lock nuts (b)

that secure each drift cutter, and remove

them from the sides of auger housing. See

Figure Figure 2-6.

2.

Turn the drift cutters around and position

them as shown in Figure 2-6 to the outside

of the auger housing.

(a)

(a)

(b)

(b)

Figure 2-6

3.

Attach drift cutters with screws (a) and

lock nuts (b) removed in Step 1.

Tool-less

1.

Remove two carriage bolts (a) and wing

nuts (b) that secure each drift cutter, and

remove them from the sides of auger

housing. See Figure 2-7.

2.

Turn the drift cutters around and position

them as shown in Figure 2-7 to the outside

of the auger housing.

(a)

(a)

(b)

(b)

Figure 2-7

3.

Attach drift cutters with carriage bolts (a)

and wing nuts (b) removed in Step 1.

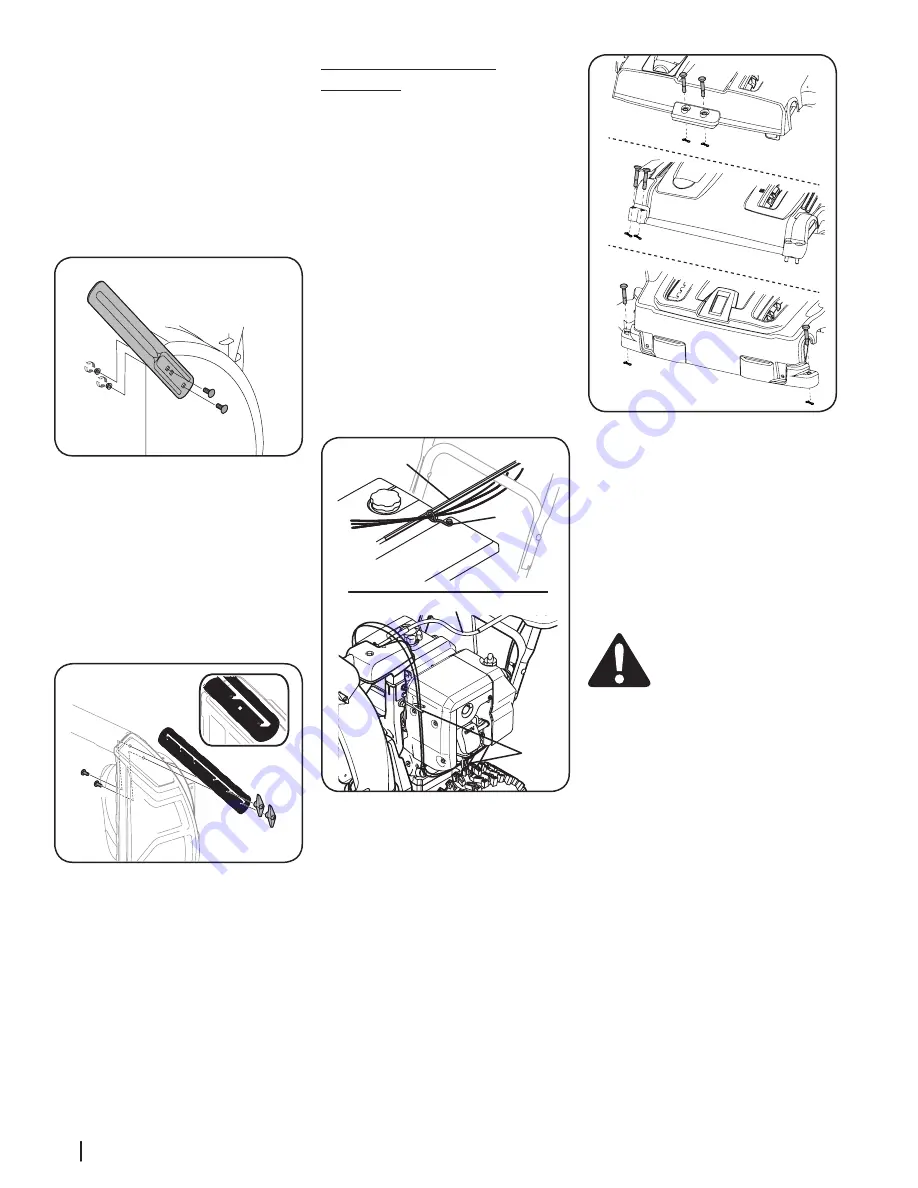

Chute Control Cable Routing

(If Equipped)

For units equipped with chute cables, ensure

they are routed properly. Chute control cables

are routed through a single wire guide (a) on top

of the engine and/or through two wire guides (b)

located on the left side of the unit.

NOTE:

For smoothest operation, cables should

all be to the left of the chute directional control

rod.

NOTE:

The number of cables routed through the

wire guides will depend on your model.

1.

Locate cable guide(s) and perform the

following:

•

Units with Top Mounted Wire Guide

(a)

- Check that all cables are properly routed

through cable guide on top of engine. See

Figure 2-8.

•

Units with Side Mounted Wire Guides

(b) - Check that all cables are properly routed

through the wire guide below the left side

of the engine and the wire guide below the

chute control head. See Figure 2-8.

(b)

(a)

(c)

(c)

Figure 2-8

Shear Pins Storage (If Equipped)

On select units, holes are provided in the rear of

the handle panel for shear pin (a) and

bow-tie cotter pin (b) storage as shown in Figure

2-9. If not provided, make sure to store them in a

safe place until needed.

NOTE:

Three stage units come with four (4) shear

pins and bow-tie cotter pins.

(a)

(b)

(a)

(b)

(a)

(b)

Figure 2-9

Adding Fuel & Oil

Refer to the Engine Operator’s Manual for

information on adding fuel and oil.

Adjustments

Skid Shoes

The snow thrower skid shoes are adjusted at

the factory, set roughly 1/8” below the shave

plate. Adjust them downward, if desired, prior to

operating the snow thrower.

CAUTION:

Use extreme caution

when on gravel and adjust auger

housing height to clear gravel or

crushed rock surfaces to avoid

picking up and throwing gravel or

crushed rock.

•

For close snow removal on a smooth

surface, raise skid shoes higher on auger

housing.

•

Use a lower position when area to be

cleared is uneven, such as a gravel

driveway.

NOTE:

If you choose to operate unit on a gravel

surface, keep skid shoes in position for maximum

clearance between ground and shave plate.

NOTE:

Some models are equipped with

reversible skid shoes and may be turned over to

increase their lifespan.

To adjust skid shoes:

1.

Loosen hex nuts, washers (if equipped)

and carriage bolts. Move skid shoes to

desired position.

2.

Make certain entire bottom surface of skid

shoe is against ground to avoid uneven

wear on skid shoes.

3.

Retighten hex nuts, washers (if equipped)

and carriage bolts securely.

See Figure 2-10.