17

S

ection

5 — P

roduct

c

are

2.

Locate the shift lever adjustment nuts (a).

See Figure 5-18.

(a)

Figure 5-18

3.

Adjust the nuts (a) up or down until the shift

lever is working properly. See Figure 5-18.

Checking the Engine Start System

WARNING

Do not allow anyone near the vehicle while testing. If the

vehicle does not pass the test, do not operate the vehicle.

1.

Sit on the operator’s seat.

2.

Place the shift lever in the NEUTRAL position.

3.

Set the parking brake and stop the engine.

4.

Move the shift lever to: LOW, HIGH, PARK or

REVERSE position. Do not step on the brake

pedal.

5.

Turn the key to START position.

6.

The engine should not crank.

7.

If it cranks see an authorized service dealer.

8.

Repeat steps 4 and 5 but when turning the

key to start position step on the brake pedal.

The engine should crank.

9.

If it does not crank see an authorized service

dealer.

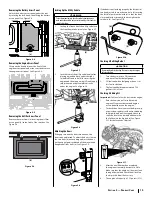

Adjusting the Shocks

There are three adjustment points on the shocks.

The rebound (a), pre-load spring (b) and damping

rate (c) can be adjusted. Refer to Figure 5-19 for the

following instructions.

C

Fa

st

Slo

w

F

S

(a)

(b)

(c)

Figure 5-19

Rebound Adjuster (a)

The rebound adjuster is located near the bottom

of the shock and controls the “bounce back” speed

of the utility vehicle. To adjust the rebound or

“bounce-back” speed, follow the steps below:

Note:

Each position has a stop or “click” to indicate

the setting.

1.

Insert a standard screw driver into the

adjustment.

2.

Rotate the screw into one of the 18 positions

between “S” (position 0) and “F” (18). Rotate

the screw clockwise (towards the “S” or “0”

position) to slow the rebound and counter-

clockwise (towards the “F” or “18” position)

to speed up the rebound.

Pre-Load Spring Adjuster (b)

The pre-load adjuster is located in the body of the

shock and controls the height of the vehicle. It can

be adjusted to accommodate for different load

situations.

Note:

This adjustment requires a spanner wrench

to complete. A spanner wrench is included in the

tool kit shipped with this utility vehicle.

1.

Using a spanner wrench, loosen the upper

lock nut.

2.

Adjust the pre-load adjuster nut to the

desired setting. Turn the pre-load adjuster

clockwise to increase the compression

force (raise the utility vehicle) and turn the

pre-load adjuster nut counter-clockwise to

decrease the compression force (lower the

utility vehicle).

Damping Rate Adjuster (c)

The compression adjuster is located on the upper

part of the shock and controls the ride of the utility

vehicle and the impact resistance of the shocks.

Note:

Each position has a stop or “click” to indicate

which of the 18 positions it is in.

1.

To increase the stiffness of the suspension

and increase the absorption of impacts,

rotate the compression adjuster screw

clockwise towards the “SLOW” (or “0”)

position.

2.

To decrease the stiffness (soften the ride)

rotate the compression adjuster screw

counter-clockwise towards the “FAST” (or

“18”) position.

To return the utility vehicle to its stock setting, use

the chart below:

Rebound

Adjuster

Pre-Load

Adjuster

Compression

Adjuster

Front

Position 7

295 mm

Position 5

Rear

Position 4

300 mm

Position 3

* -- These setting are based on a “full load” condition.

250 lb (113 kg) driver, 250 lb (113 kg) passenger and

500 lb (227 kg) cargo load.

Service

WARNING

To avoid personal injury, be sure to check and service the

vehicle on a flat surface with the engine off and the parking

brake ON. If servicing under the cargo bed, be sure that the

cargo bed is supported so that it can not inadvertently close.

Do not touch muffler or exhaust pipes while they are hot;

Otherwise, severe burns could result.

Changing the Oil

WARNING

Be sure to stop the engine before replacing oil. Allow engine

to cool down sufficiently, oil can be hot and can burn.

1.

Park the vehicle on flat surface and raise the

cargo bed.

2.

To drain the used oil, remove the drain plug

at the bottom of the engine and completely

drain the oil into an oil pan.

3.

After draining, reinstall the drain plug.

4.

Fill with the new oil up to the upper notch

on the dipstick.

Note:

Oil with an American Petroleum

Classification (API) service classification

should be used. 10W/40SL, JASO-MA grade

oil is recommended.

5.

The engine oil capacity is 2.22 quarts (2.1L)

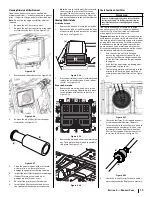

Replacing Oil Filter

WARNING

Be sure to stop the engine before replacing oil filter. Allow

engine to cool down sufficiently, oil can be hot and can burn.

1.

Park the vehicle on a flat surface, remove

the seat and open the engine access cover.

2.

Remove the oil filter (a). See Figure 5-20.

(a)

Figure 5-20

3.

Put a film of clean engine oil on the rubber

seal of the new filter.

4.

Tighten the filter until it contacts the

mounting surface.

5.

Tighten filter by hand an additional 1/2-turn only.

Draining the PCV Accumulator

The PCV accumulator should be drained at each

oil changed to remove oil condensation. There are

two PCV accumulators, one near the front of the air

intake box and one near the rear. To drain the PCV

accumulator, pinch the valve at the bottom of the

tube and allow the condensation to run out. See

Figure 5-21.

Figure 5-21