6

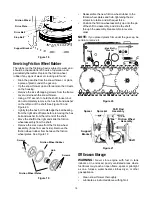

Figure 3

NOTE:

If the connector is not properly assembled, the

shift rod will pivot and you will not be able to change

speeds or change directions.

•

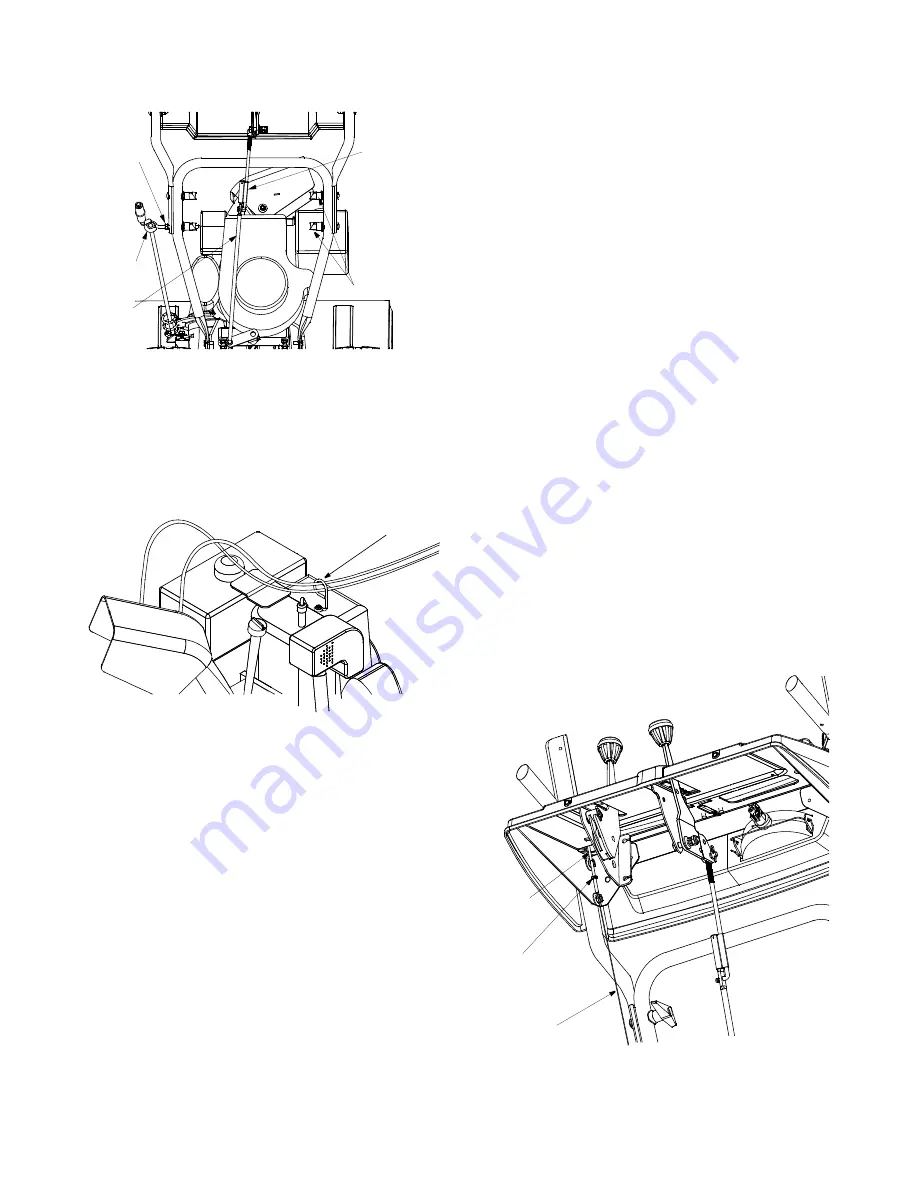

If not already attached, slip the cables that run from

the handle panel to the chute into the cable guide

located on top of the engine. See Figure 4.

Figure 4

•

Unwrap the headlight wire, which is attached to the

headlight beneath the handle panel.

•

Wind the headlight wire around the right handle

until excess slack is removed.

•

Plug the wire from the right side of the engine,

beneath the fuel tank.

Final Adjustments

Auger Control Adjustment

Check the adjustment of the auger control as follows:

•

Push forward on the auger control (Refer to Figure

7 ) until the small rubber bumper contacts the upper

handle. There should be slack in the cable. See

Figure 5 .

•

Release the auger control. The cable should be

straight. Make certain you can depress the auger

control against the left handle completely without

using excess force.

If adjustment is necessary, proceed as follows:

•

Loosen the jam nut and thread the cable in (for less

slack) or out (for more slack) as necessary. See

Figure 5 .

•

Recheck the adjustment before retightening the

jam nut against the cable.

Traction Control and Shift Lever Adjustment

NOTE:

It is easier to maneuver a non-running snow

thrower with both track steering controls held in

simultaneously.

To check the adjustment of the traction control and shift

lever, proceed as follows:

•

Move the shift lever into the sixth (6) position.

a. With the traction control (see Figure 7 )

released, push the snow thrower forward,

then pull it back. Disregarding the overall

weight of the snow thrower, the machine

should otherwise move freely.

b. Engage the traction control, and attempt to

move the machine both forward and

rearward. You should experience resistance

as the wheels should not be turning.

•

Move the shift lever into the fast reverse (R2)

position and repeat the previous steps (a & b).

If you experienced resistance either when repositioning

the shift lever (see Figure 7 ) from position 6 to R2 or

when attempting to move the machine forward or

rearward with the traction control released, your snow

thrower’s traction control is in need of adjustment and

you should NOT operate the snow thrower before

completing the adjustment as follows:

Figure 5

Eyebolt

Wing Knobs

Shift Rod

Hex Nut

Connector

Lower

Shift Rod

Cable Guide

“Z” End

Jam Nut

Auger Control Cable