5

travel (known as top dead center). Check that:

•

The piston is at the top of its travel by looking in the spark

plug hole (Fig. 29)

•

Both rocker arms move freely, and both valves are closed.

If these statements are not true, repeat this step.

6. Slide the feeler gauge between the rocker arm and the valve

return spring. Measure the clearance between the valve stem

and rocker arm (Fig. 30). Measure both the intake and exhaust

valves.

The recommended clearance for both intake and exhaust is

0.003 – 0.006 in. (0.076 – 0.152 mm). Use a standard automotive

0.005 in. (0.127 mm) feeler gauge. The feeler gauge should slide

between the rocker arm and valve stem with a slight amount of

resistance, without binding. See Figure 30.

7. If the clearance is not within specification:

a. Turn the adjusting nut using a 5/16 inch (8 mm) wrench or nut

driver (Fig. 30).

•

To increase clearance, turn the adjusting nut

counterclockwise.

•

To decrease clearance, turn the adjusting nut clockwise.

b. Recheck both clearances, and adjust as necessary.

8. Reinstall the rocker arm cover using a new gasket (Fig. 29). Torque the screw to: 20–30 in•lb

(2.2–3.4 N•m).

9. Check the spark plug and reinstall. See Replacing the Spark Plug.

10. Reinstall the spark plug wire.

11. Reinstall the engine cover. Check alignment of the cover before tightening the screws. Tighten screws.

NOTE: Make sure that the screws are reinstalled into their

original holes (Fig. 28).

REPLACING THE SPARK PLUG

Use a replacement part number

753-05784 or Champion spark

plug #RDZ4H. The correct spark gap is 0.025 in. (0.635 mm).

1. Stop the engine and allow it to cool.

2. Open the spark plug cover (Fig. 31).

3. Grasp the plug wire firmly and pull the cap from the spark plug.

4. Clean dirt from around the spark plug. Remove the spark

plug from the cylinder head by turning a 5/8 in. socket

counterclockwise.

5. Replace cracked, fouled or dirty spark plug. Set the spark gap

at 0.025 in. (0.635 mm) using a feeler gauge (Fig. 32).

6. Install a correctly-gapped spark plug in the cylinder head. Turn

the 5/8 in. socket clockwise until snug.

7. Reinstall the spark plug cover.

If using a torque wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

CLEANING AND STORAGE

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These

procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills such as replacement or

repair of the emission control devices and system. If unsure about these procedures or tools

are not available; take the unit to a qualified service dealer. Call

1-877-282-8684 for more

information.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be

performed by a qualified service dealer.

NOTE: Please read the EPA statement that came with the unit for a complete listing of terms and

coverage for the emissions control devices, such as the spark arrestor, muffler, carburetor,

etc.

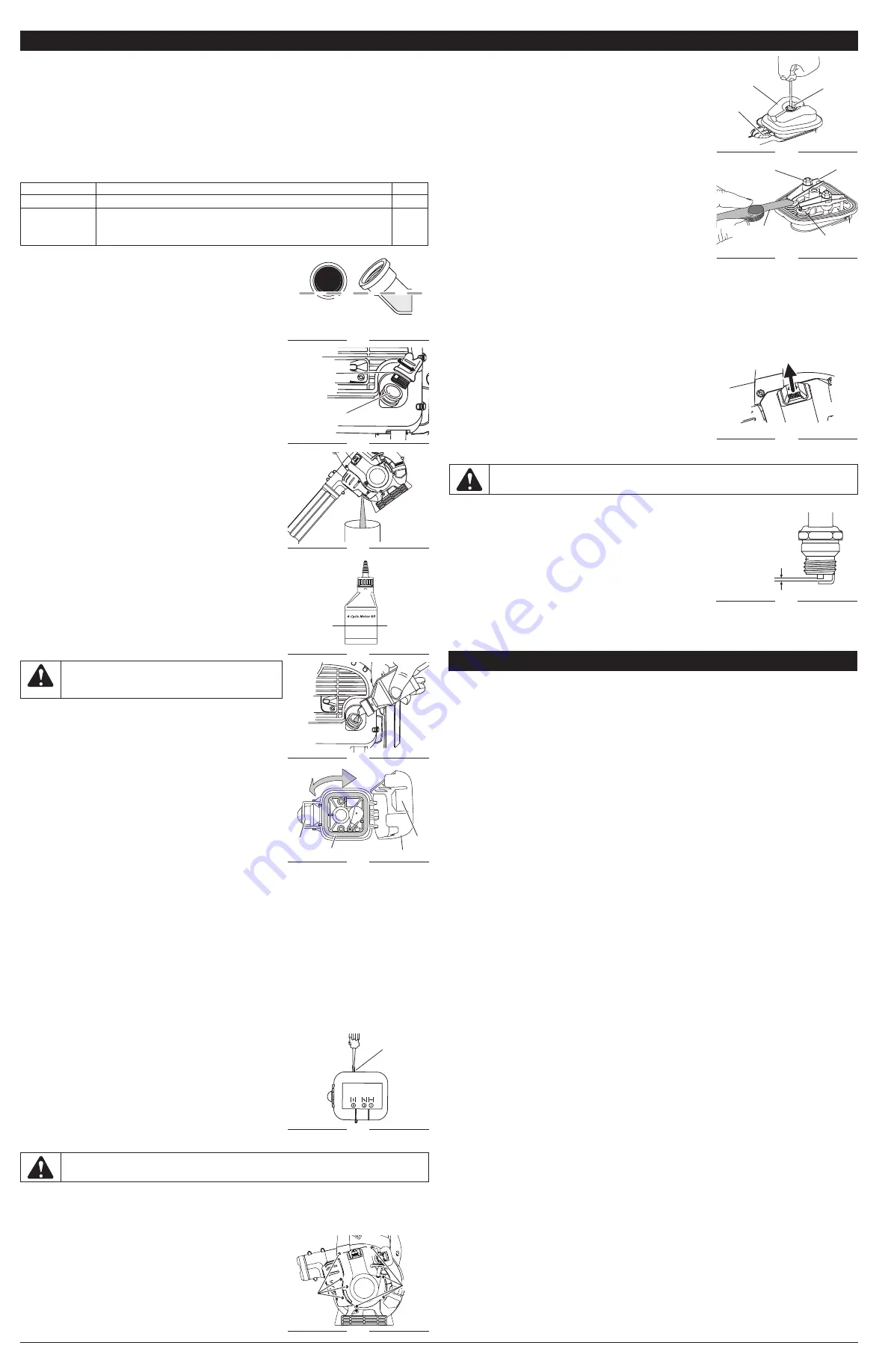

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil level in

the crankcase cannot be overemphasized. Check oil before each

use:

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the engine on a level surface.

3. Clean the area around the oil plug before removing it. Keep

dirt, grass clippings, and other debris out of the engine.

4. Remove the oil plug (Fig. 22).

5. Look into the oil fill hole (use a flashlight if needed). The oil

should be just touching the innermost thread (Fig. 21).

6. If the oil level is not touching the innermost thread on the oil fill

hole, add a small amount of oil to the oil fill hole and recheck

(Fig. 21). Repeat this procedure until the oil level reaches the

innermost thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE: Make sure the O-ring is in place on the oil plug when

checking and changing the oil (Fig. 22).

CHANGING THE OIL

Change the oil while the engine is still warm. The oil will flow freely

and carry away more impurities.

1. Remove the oil fill plug.

2. Pour the oil out of the oil fill hole and into a container by

tipping the unit to a vertical position (Fig. 23). Allow ample

time for complete drainage.

3. Wipe up any oil residue on the unit and clean up any oil that

may have spilled. Dispose of the oil according to Federal,

State and local regulations.

4. Refill the crankcase with 2.03 fl.oz. (60 ml) of SAE 30 SJ oil

(Fig. 25).

NOTE: Use the bottle and spout saved from initial use to

measure the correct amount of oil. The fill line on the

bottle’s label measures approximately 2.03 fl.oz. (60 ml)

(Fig. 24).

5. Check the level, See Checking the Oil Level.

6. Once full, replace the oil plug.

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Failure to maintain the air filter will VOID the warranty.

1. To open the air filter cover, push the tab on the left side of the

cover inward and pull the air filter cover slightly out and to the

right (Fig. 26).

2. Remove the air filter (Fig. 26).

3. Wash the filter in detergent and water. Making sure to rinse the

filter thoroughly and allow it to dry.

4. Lightly coat the filter with clean SAE 30 motor oil.

5. Squeeze the filter to spread and remove excess oil.

6. Replace the filter.

NOTE: Operating the unit without the air filter will VOID the

warranty.

7. To reinstall the air filter cover, position the hooks on the right

side of the air filter cover into the slots at the right side of the

back plate (Fig. 26).

8. Swing the cover to the left and press closed so the air filter cover tab snaps into the slot on the

back plate (Fig. 26).

IDLE SPEED ADJUSTMENT

The idle speed of the engine is adjustable. An idle adjustment screw is between the air filter cover and

the engine starter housing (Fig. 27).

NOTE: Careless adjustments can seriously damage to the unit. A qualified service dealer should

make carburetor adjustments.

If, after checking the fuel and cleaning the air filter, the engine still will not idle, adjust the idle speed

screw as follows:

1. Start the engine and warm up according to the Starting/Stopping Instructions.

2. Release the trigger and let the engine idle. If the engine stops, insert a small Phillips screwdriver in

between the air filter cover and the engine cover (Fig. 27). Turn the idle speed screw 1/8 of a turn

clockwise at a time until the engine idles smoothly.

3. If the engine appears to be idling too fast, turn the idle speed screw

counterclockwise 1/8 of a

turn at a time (as needed), to reduce idle speed.

Checking the fuel, cleaning the air filter, and adjusting the idle

speed should solve most engine problems. If not, and all of the

following are true:

•

the engine will not idle

•

the engine hesitates or stalls on acceleration

•

there is a loss of engine power

take the unit to a qualified service dealer.

ROCKER ARM CLEARANCE

This requires disassembly of the engine. If you feel unsure or

unqualified to perform this, take the unit to a qualified service dealer.

•

The engine must be cold when checking or adjusting the rocker arm clearance.

•

This task should be performed inside, in a clean, dust free area.

1. Remove the 8 engine cover screws with the appropriate tool (Fig. 28), then remove the cover.

NOTE: Make sure to store the screws so that they can be reinstalled into their original holes.

2. Disconnect the spark plug wire.

3. Clean dirt from around the spark plug and rocker arm cover.

Remove the spark plug from the cylinder by turning a 5/8 in.

socket counterclockwise.

4. Remove the screw holding the rocker arm cover with the

appropriate tool (Fig. 29). Remove the rocker arm cover and

gasket.

5. Turn the flywheel slowly to bring the piston to the top of its

Fig. 23

Fig. 25

Fig. 31

MAINTENANCE INSTRUCTIONS

FREQUENCY

MAINTENANCE REQUIRED

SEE

Every 10 hours

Clean air filter

p. 5

After the first 10

hours and every

40 hours

Change oil

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 5

p. 5

p. 5

WARNING:

To avoid serious personal injury,

always turn the unit off and allow it to cool before

cleaning or maintaining it.

WARNING:

To avoid serious personal injury, always turn the unit off and allow it to cool

before cleaning or maintaining it.

Fig. 21

Oil Fill Line

Fig. 24

Fill Level

Fig. 27

Idle Adjustment

Screw

Fig. 30

Rocker Arm

Adjustment Nut

0.003–0.006 in.

(0.076–0.152 mm)

Feeler Gauge

Valve

Stem

Fig. 22

O-Ring

Oil Plug

Oil Fill Hole

Fig. 26

Air Filter Cover

Slot

Air Filter

Tab

Fig. 28

Screws

Screws

Fig. 29

Screw

Rocker

Arm

Cover

Spark

Plug

Hole

Fig. 32

0.025 in.

(0.635 mm)

WARNING:

Do not sand blast, scrape or clean spark plug electrodes. Grit in the engine

could damage the cylinder.

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household

cleaners that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can

damage plastic housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

•

Never store the unit with fuel in the tank where fumes may reach an open flame or spark.

•

Allow the engine to cool before storing.

•

Lock up the unit to prevent unauthorized use or damage.

•

Store the unit in a dry, well-ventilated are a.

•

Store the unit out of the reach of children.

Long Term Storage

1. Drain all gasoline from the gas tank into a container. Do not use gas that has been stored for more

than 30 days. Dispose of the old gasoline in accordance with federal, state and local regulations.

2. Start the engine and allow it to run until it stalls. This ensures that all gasoline has been drained

from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5 drops of high quality motor oil into the

cylinder. Pull the starter rope slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the cylinder before attempting to start

the blower after storage.

4. Change the oil, referring to Changing the Oil. Dispose of the old oil in accordance with federal,

state and local regulations.

5. Thoroughly clean the unit and inspect for any loose or damaged parts. Repair or replace damaged

parts and tighten loose screws, nuts or bolts. The unit is ready for storage.

Summary of Contents for BV 428

Page 19: ...19 NOTES ...

Page 20: ...20 NOTES ...

Page 21: ...21 NOTES ...

Page 22: ...22 NOTES ...

Page 23: ...23 NOTES ...