20

Inspection of Cooling System

Hoses

Check the cooling system hoses and fan belt for

any cracks or deterioration after every 100 hours of

operation. Check for loose hose connections. Replace

any damaged hoses and tighten any loose connections.

Replace a worn or damaged fan belt.

Changing the Engine Coolant

The engine coolant should be drained and replaced with

new coolant solution every 2 years or 500 hours.

Dilute the antifreeze with water at a 1 : 1 ratio to mix the

coolant solution (50% antifreeze : 50% water).

Change the engine coolant as follows:

1. Drain the coolant when the engine is cold.

2. Place the unit on a level surface and raise the hood.

3. Slide the overflow reservoir upward and off the

reservoir bracket to access the radiator drain plug.

4. Locate the radiator drain plug in the lower right rear

corner of the radiator.

5. Place a suitable container beneath the drain plug

and remove the cap from the overflow reservoir.

6. Turn the drain plug counterclockwise to re-move.

Allow as much of the old coolant as possible to drain

from the system.

5

WARNING

Servicing

Your

Utility

Vehicle

WARNING: Coolant is a toxic substance.

Dispose of in an environmentally safe

manner. Contact your area EPA office for

proper disposal methods and recycling

center locations.

7. Reinstall the drain plug and turn clockwise until fully

tightened.

8. Turn the radiator cap counterclockwise to the first

stop, then push downward on the cap and turn

counterclockwise to remove.

9. In stages, SLOWLY pour the coolant solution into the

filler neck, allowing as much air as possible to escape

through the neck. Fill to the overflow flange of the filler

neck.

10. Wait a few minutes to allow air to escape through

the filler neck and refill as needed, then reinstall the

radiator cap.

11. Fill the overflow reservoir to the “FULL” mark.

12. Start the engine and allow it to run for a short period.

Stop the engine.

13. Recheck the coolant level in the overflow reservoir

and refill as needed. Reinstall the reservoir cap.

Servicing the Fuel Filter

WARNING: Do not service the fuel filter

when tractor is hot or near any source of

ignition. Allow the tractor to cool.

The utility vehicle is equipped with an in-line fuel filter

located on the right side of the engine.

WARNING: Diesel fuel is a toxic substance.

Dispose of in an environmentally safe

manner. Contact your area EPA office for

proper disposal methods and recycling

center locations.

Draining The Fuel Filter

The fuel filter is equipped with a valve to drain conden-

sate (water) that has separated from the diesel fuel and

settled at the bottom of the filter.

Drain the condensate from the fuel filter before each use.

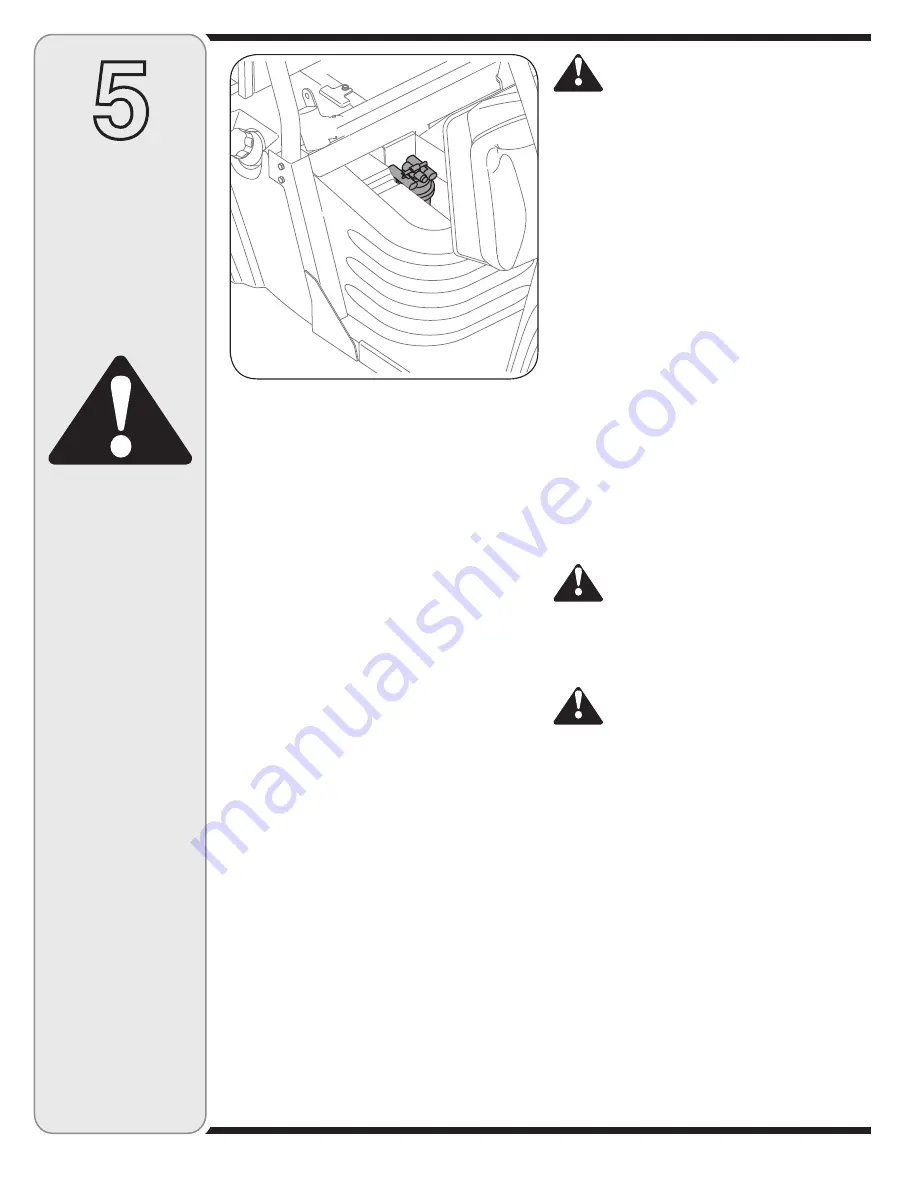

You can access the fuel filter beneath the passenger

seat. Refer to Figure 11.

Do not service the fuel

filter when tractor is

hot or near any source

of ignition. Allow the

tractor to cool.

Diesel fuel is a toxic

substance. Dispose of

in an environmentally

safe manner. Contact

your area EPA office

for proper disposal

methods and recycling

center locations

Figure 11

Coolant is a toxic

substance. Dispose of

in an environmentally

safe manner. Contact

your area EPA office

for proper disposal

methods and recycling

center locations.

Summary of Contents for J466

Page 28: ...28 NOTES...

Page 29: ...29 NOTES...