23

•

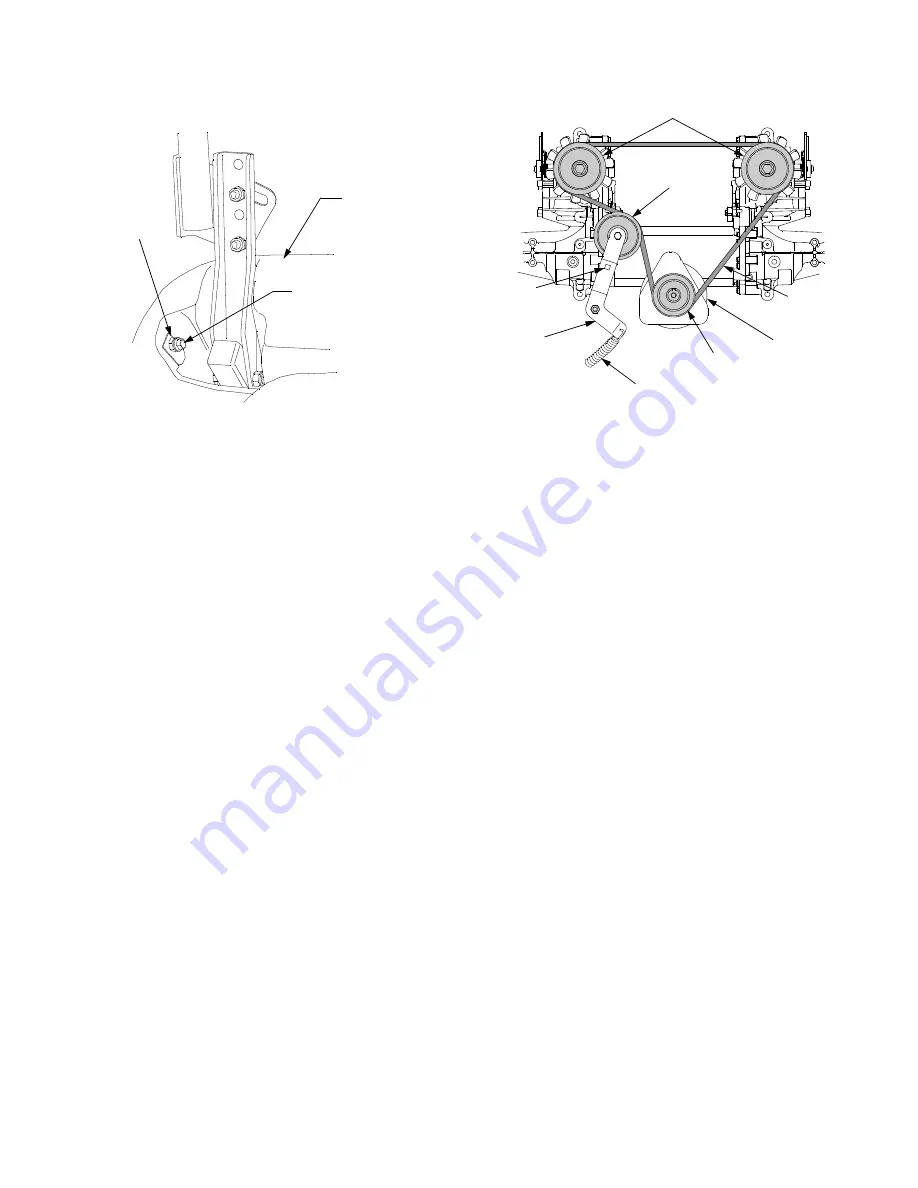

Locate the applicable stop bolt on the left or right

console. See Figure 24.

Figure 24

•

Loosen the jam nut on the stop bolt, then turn the

stop bolt counterclockwise to make it longer.

Recheck the tracking and fine tune the adjust-

ment as necessary.

NOTE: If the stop bolt is adjusted too far, the

tracking problem will change sides. Make fine

tuning adjustments by shortening the same bolt.

•

Tighten the jam nut against the console and repo-

sition the control lever if necessary.

TRANSMISSION DRIVE BELT

If the transmission drive belt becomes worn and

causes the drive transmissions to slip, the drive belt

must be replaced. To replace the drive belt, proceed

as follows:

•

Remove the deck drive belt from the PTO clutch

on the bottom of the engine following the instruc-

tions in Deck Removal, SECTION 5: MOWER

DECK.

•

From beneath the rear of the tractor, insert a 3/8

inch drive ratchet into the square hole of the drive

idler bracket. See Figure 25.

Figure 25

•

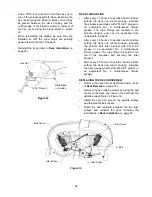

Using the ratchet for leverage, pivot the idler

bracket and idler pulley away from the backside

of the ‘V" belt; then lift the belt off and above the

engine pulley and off the idler pulley.

•

With the belt loose, lift the belt off, up and over

the two transmission drive pulleys. Remove the

belt from the engine and idler pulleys.

•

Loop the new belt and slide over and onto the

two transmission pulleys.

•

Route the belt above the idler bracket back to the

engine drive pulley. Lift the belt over the PTO pul-

ley and above the engine drive pulley.

•

Using the ratchet for leverage, pivot the idler

bracket and idler pulley against the spring ten-

sion; then slip the belt down into the engine drive

pulley and onto the idler pulley.

•

Release the idler bracket so that the idler pulley

tightens against the back side of the belt and ten-

sions the drive belt.

•

Reinstall the deck drive belt.

Console

Stop Bolt

Jam Nut

Transmission

Drive Pulley

Idler

Pulley

Engine

Pulley

Drive

Belt

Idler

Bracket

Idler Brkt.

Spring

Square

Hole

PTO

Pulley