RZT-S Zero

84

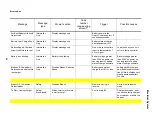

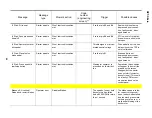

Control panel faults

The control panel consists of the:

•

The contactor assembly

•

The master ground bus

•

4 controllers

•

A communication harness

•

Aluminum back plate

The contactor assembly can be thought of as the main

power distribution center of the system. There is a master

relay and four fused leads that sends 48 volts to the con-

trollers and the master ground bus is the common ground-

ing point for the voltage to return to the batteries.

See Figure 5.51.

NOTE:

The contactor assembly is NOT serviceable.

Opening the contactor assembly will void the

warranty.

•

While the key switch is in the “ON” position, the VCM will send battery voltage out pin 9 of the 12 pin con-

nector of the VCM. The 48 volts enters the contactor assembly through pin 4 of the contactor’s main har-

ness connection. The battery voltage by-passes the master relay, exiting the contactor and entering the

controllers through the red fused power leads.

•

This battery voltage will charge the pre-charge capacitors in each controller. The pre-charge capacitors

prevents a large inrush of current when the master relay is closed.

•

When the pre-charge capacitors are charged the controllers voltage levels will be equal to battery voltage.

•

Once the VCM senses battery voltage in the controllers, it will send a signal to the contactor assembly to

energize the master relay.

•

The master relay inside the contactor assembly will r48 volts from the VCM through pin 2 of the

contactor’s main harness connection. The 48 volts returns to the VCM through pin 3 of the contactor’s

main harness connection. Once the relay closes, battery voltage is passed to the controllers through the

red, fused leads.

•

When the mower is “ON”, the VCM will send a 48 volt signal to the contactor through pin 5 of the contac-

tor’s main harness connection. That 48 volt signal is passed through the contactor on to the controllers

through the white wire in the communication harness. The 48 volt signal will turn on all of the controllers.

Figure 5.51

Contactor assembly

Fused leads

Controller

Communication harness

Master ground bus

Summary of Contents for RZT-S Zero

Page 2: ......

Page 42: ...RZT S Zero 38 ...

Page 112: ...RZT S Zero 108 ...

Page 154: ...NOTES ...

Page 155: ......

Page 156: ...MTD Products Inc Product Training and Education Department FORM NUMBER 769 08008 02 05 2013 ...