10

s

ectiOn

2— a

sseMbly

& s

et

-u

p

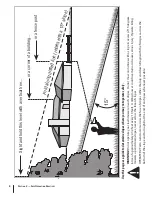

Position Drive Control levers

The drive control levers of the tractor are lowered for shipping

purposes. The flange lock nuts, hex screws, and flat washers that

normally secure the control levers in their operating position

are unfastened and installed in the slotted holes of the control

levers for shipment. The control levers must be repositioned to

operate the tractor. To reposition the control levers for operation,

proceed as follows:

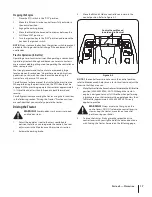

Remove the hex screw, flat washer, and flange lock nut from the

1.

slot of one of the drive control levers.

Lift and swing that control lever upward until the slotted hole in

2.

the lever bracket aligns with one of the holes in the pivot

bracket. See Fig. 3-4.

Slide the flat washer onto the hex screw. From the outside, insert

3.

the hex screw with washer through the control lever slot

and the hole of the pivot bracket. Secure with the flange

lock nut. See Fig. 3-4.

Note the relative position of the control lever to the pivot

4.

bracket, then repeat the previous steps to reposition the

other control lever in approximately the same position.

Refer to “Adjusting the Drive Control Levers” in the

5.

Maintenance & Adjustments for instructions on the final

adjustment of the levers.

Control Lever

Flange

Lock Nut

Slotted Hole

Washer

Hex Screw

Lift Control

Lever Upward

Pivot

Bracket

Figure 3-4

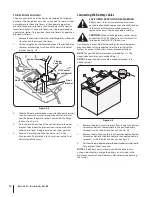

Connecting the Battery Cables

CALIFORNIA PROPOSITION 65 WARNING

!

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

CAUTION:

When attaching battery cables, always

connect the POSITIVE (Red) wire to its terminal first,

followed by the NEGATIVE (Black) wire.

For shipping reasons, both battery cables on your equipment

may have been left disconnected from the terminals at the

factory. To connect the battery cables, proceed as follows:

NOTE:

The positive battery terminal is marked Pos. (+). The

negative battery terminal is marked Neg. (–).

NOTE:

If the positive battery cable is already attached, skip

ahead to step 2.

Remove the plastic cover, if present, from the positive battery

1.

terminal and attach the red cable to the positive battery

terminal (+) with the bolt and hex nut. See Fig. 3-5.

Remove the plastic cover, if present, from the negative battery

2.

terminal and attach the black cable to the negative battery

terminal (–) with the bolt and hex nut. See Fig. 3-5.

Position the red rubber boot over the positive battery terminal to

3.

help protect it from corrosion.

NOTE:

If the battery is put into service after the date shown

on top/side of battery, charge the battery as instructed in the

Maintenance section your Operator’s Manual prior to operating

the tractor.

Figure 3-5

Summary of Contents for RZT50VT

Page 40: ...Notes 11 40 ...

Page 41: ...41 Section 11 Notes ...