12

S

ection

2— A

SSembly

& S

et

-U

p

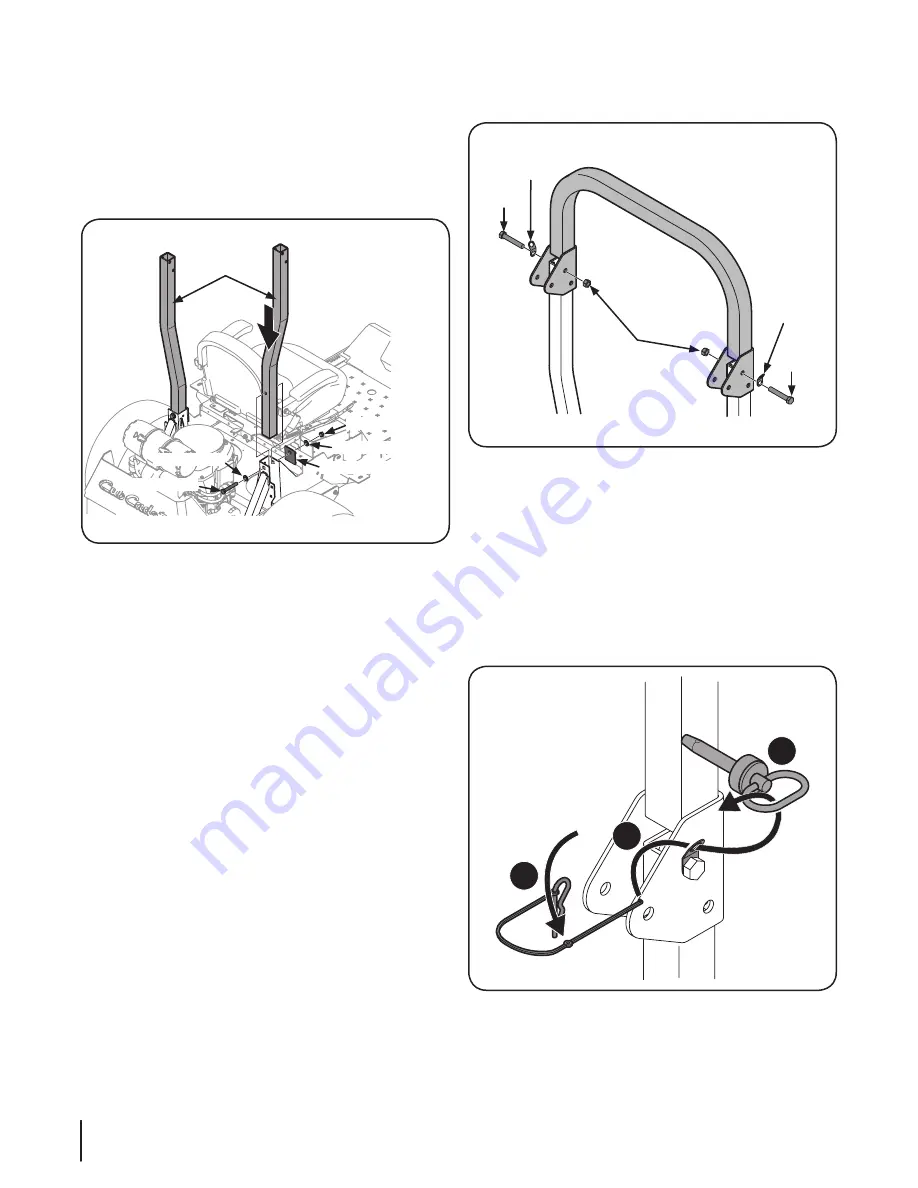

Install Roll Over Protective System (ROPS)

The Roll Over Protective System (ROPS) has not been installed

on your unit for shipping purposes. Using the hardware found in

the Roll Over Protective System container, install it on your unit

as follows:

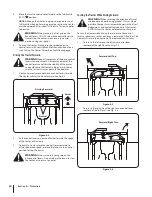

1.

Insert each of the lower section ROPS tubular posts into the

brackets welded to the tractor main frame. See Fig. 3-3.

ROPS Lower

Sections

Carriage Bolt

Flat Washer

Flat Washer

Reinforced Plate

Flange Lock Nut

Figure 3-3

NOTE:

The ROPS folding stop should be positioned toward

the rear of the unit. See Fig. 3-3.

2.

Insert the carriage bolts (one per side) in the frame brackets

and ROPS posts from the front toward the rear. See Fig.

3-2. Alternately from the rear toward the front if access is

restricted.

NOTE:

The mounting hardware is accessible from the rear

of the machine with the use of extensions. Also, access can

be gained by reaching in from the sides over the tires fuel

tanks.

3.

Install the reinforced plates and flange lock nuts, but do

not tighten. See Fig. 3-3.

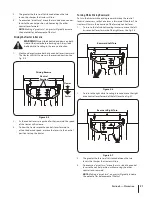

4.

Install the upper ROPS section onto the lower ROPS “posts”.

Install the bolts and nuts. See Fig. 3-4.

Bolt

Retaining

Washer

Lock Nuts

Bolt

Retaining

Washer

Figure 3-4

5.

Tighten upper ROPS section bolts after both RH & LH

hardware is installed.

6.

Tighten the frame mounting hardware to 80-90 lb.-ft.

torque. See Fig. 3-3.

NOTE:

Make sure tubular upright posts are absolutely

tight within welded bracket. If the ROPS is not absolutely

tight after tightening hardware to 80-90 ft-lbs, additional

tightening is needed.

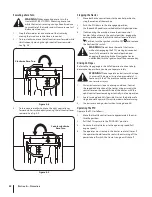

7.

Route the nylon lanyard as shown in Fig. 3-5. Be sure to

secure the lanyard to the retaining clip and clevis pin.

A

B

C

Figure 3-5