S

ection

6 — M

aintenance

& a

djuStMentS

27

Maintenance

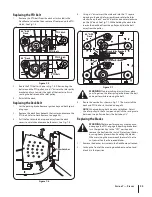

Checking the Safety Interlock Circuits

Periodically check the safety interlock circuits to ensure they are

working properly. If a safety circuit is not working as designed,

contact you Cub Cadet dealer to have the tractor inspected. DO

NOT operate the tractor if any safety circuit is not functioning

properly. To check the safety circuits, proceed as follows:

1.

Sitting in the tractor seat with both drive pedals in

the neutral position, disengage the parking brake and

momentarily turn the ignition switch to the start position.

The engine should not crank.

2.

Engage the parking brake and pull the PTO knob upward to

the engaged position. Momentarily turn the ignition switch

to the start position; the engine should not crank.

3.

Push the PTO knob downward to the disengaged position

and move both drive pedals to the neutral position and

disengage the parking brake; then lift upward from the

operator’s seat. The engine should stop.

4.

With both drive pedals in the neutral position and the

parking brake engaged, engage the PTO knob. Lift upward

from the operator’s seat; the engine should stop.

WARNING!

Before performing any maintenance or

repairs, disengage the PTO, move the drive pedals to

the neutral position, engage the parking brake, stop

the engine and remove the key to prevent

unintended starting.

Engine

Refer to the Engine Operator’s Manual for all engine maintenance

intervals, procedures, specifications and instructions.

NOTE:

Maintenance, repair, or replacement of the emission control

devices and systems which are being done at owner’s expense may

be performed by any engine repair establishment or individual.

Warranty repairs must be performed by a Cub Cadet Dealer

.

Hydraulic Oil Tank and Filter

If the level in the expansion reservoir under the falls below 1⁄4”

above the bottom of the reservoir, add oil until it reaches the

correct level.

To change the hydraulic oil and filter, see an authorized Cub

Cadet Dealer.

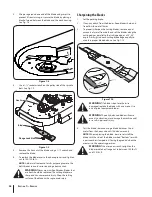

Changing the Engine Oil

WARNING

! If the engine has been recently run,

the engine, muffler and surrounding metal surfaces

will be hot and can cause burns to the skin. Exercise

caution to avoid burns.

Maintain oil level as instructed in engine manual. Be careful not

to spill oil on any of the belts.

To complete an oil change, proceed as follows:

5.

Run the engine for a short time to warm the engine oil. The

oil will flow more freely and carry away more impurities.

Use care to avoid burns from hot oil.

6.

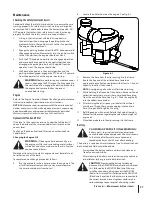

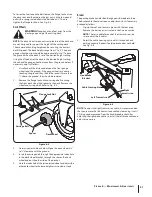

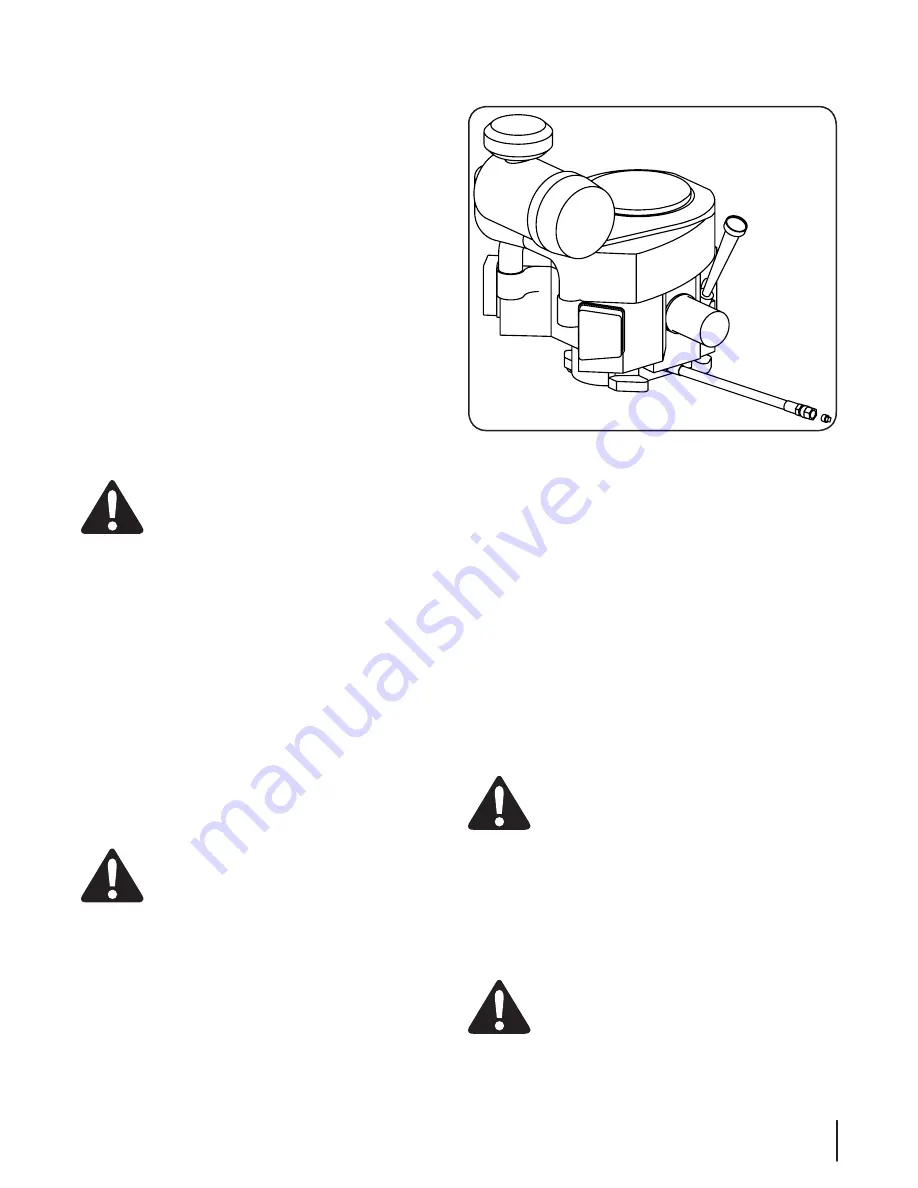

Locate the oil drain hose on the engine. See Fig. 6-1.

Figure 6-1

7.

Remove the hose from the clip securing it to the frame.

8.

Route the free end of the oil drain hose toward an

appropriate oil collection container with at least a 2.5 quart

capacity, to collect the used oil.

NOTE:

Avoid getting oil on the muffler when draining.

9.

While holding the free end of the oil drain hose over the oil

collection container, unscrew the square-head hose plug

from the end of the hose. See Fig. 6-1. Drain the engine oil

into the collection container.

10.

After draining the oil, wipe any residual oil from the oil

drain hose. Thread the square head plug into the drain

hose fitting and fully tighten the plug.

11. Refill the engine with new oil. Refer to the Engine Operator’s

Manual for information regarding the volume and weight of

engine oil.

12.

Place the hose back into the clip securing it to the frame.

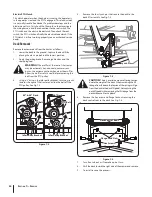

Battery

CALIFORNIA PROPOSITION 65 WARNING

!

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

The battery is sealed and is maintenance-free. Acid levels cannot

be checked and fluid can not be added.

•

Always keep the battery cables and terminals clean and

free of corrosive build-up.

•

After cleaning the battery and terminals, apply a light coat

of petroleum jelly or grease to both terminals.

CAUTION:

If removing the battery for cleaning,

disconnect the NEGATIVE (Black) wire from its terminal

first, followed by the POSITIVE (Red) wire. When re-

installing the battery, always connect the POSITIVE

(Red) wire its terminal first, followed by the NEGATIVE

(Black) wire. Be certain that the wires are connected to

the correct terminals; reversing them could result in

serious damage to your engine’s alternating system.