S

ection

5— o

peration

22

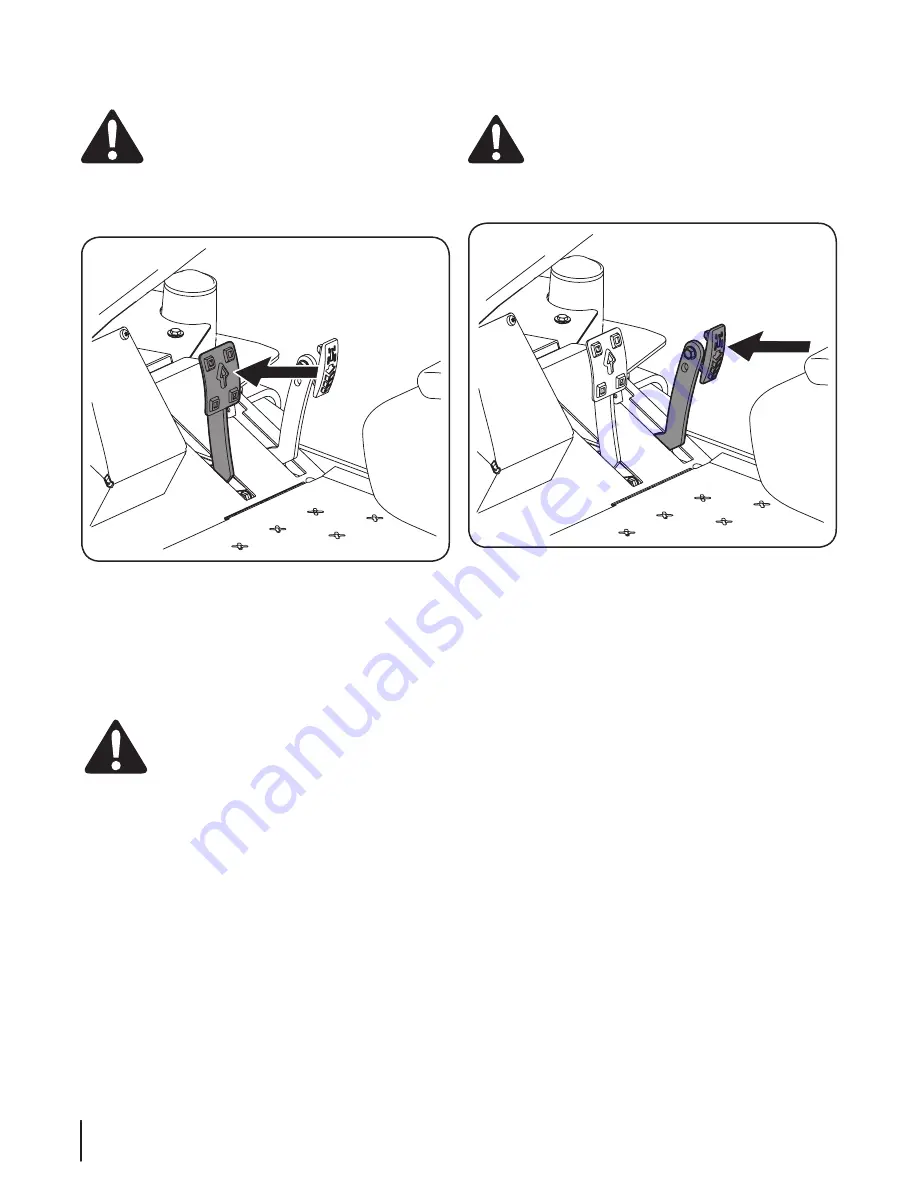

Driving the Tractor Forward

WARNING!

Keep all movement of the drive pedals

slow and smooth. Abrupt movement of the pedals

can affect the stability of the tractor and could cause

the tractor to flip over, which may result in serious

injury or death to the operator.

1.

Slowly push the forward drive pedal forward. The tractor

will start to move forward. See Figure 5-1.

Figure 5-1

2.

As the forward drive pedal is pushed farther forward the

speed of the tractor will increase.

3.

To slow the tractor, slowly release the forward drive pedal

to attain the desired speed, or allow to pedal to return the

neutral position to stop the tractor.

Turning the Tractor While Driving Forward

WARNING!

When reversing the direction of travel,

we recommend performing gradual ‘U’ turns where

possible. Sharper turns increase the possibility of turf

defacement, and could affect control of the tractor.

ALWAYS slow the tractor before making sharp turns.

To turn the tractor while driving forward, use the steering wheel

to turn in the direction you wish to travel.

1.

To turn to the left, turn the steering wheel counter-

clockwise (to the operator’s left).

2.

To turn to the right, turn the steering wheel clockwise (to

the operator’s right).

3.

The greater the distance the steering wheel is turned, the

sharper the tractor will turn.

4.

To execute a “pivot turn,” move the steering wheel so that

the inside wheel is angled at approximately 88 degrees and

the turn side tire will not rotate.

NOTE:

Making a “pivot turn” on grass will greatly increase

the potential for defacement of the turf as well as potential

damages to the traction surface and the tire.

Driving the Tractor In Reverse

WARNING!

Always look behind and down on both

sides of the tractor before backing up. Always look

behind while traveling in the reverse direction.

1.

Slowly push the reverse drive pedal forward. The tractor

will start to move in the reverse direction. See Figure 5-2.

Figure 5-2

2.

As the reverse drive pedal is pushed farther forward the

speed of the tractor will increase.

3.

To slow the tractor release the reverse drive pedal to attain

the desired speed, or allow the pedal to return to the

neutral position to stop the tractor.

Turning While Driving Rearward

To turn the tractor while driving rearward, use the steering wheel

to turn in the direction you wish to travel.

1.

To turn to the left while traveling in reverse, turn the

steering wheel clockwise (to the operator’s right).

2.

To turn to the right while traveling in reverse, turn the

steering wheel counter-clockwise.

3.

The greater the distance the steering wheel is turned, the

sharper the tractor will turn.

4.

To execute a “pivot turn,” move the steering wheel so that

the inside wheel is angled at approximately 88 degrees and

the turn side tire will not rotate.

NOTE:

Making a “pivot turn” on grass will greatly increase

the potential for defacement of the turf as well as potential

damages to the traction surface and the tire.