CUB CRAFTERS, INC.

CC11-160 MAINTENANCE MANUAL

6.4

Manual number SSC10000AMM

Page: 2

Date: 04/18/2013

1.

GENERAL

This section describes the process and method of repairing fabric and non-structural metal or

composite components.

2

PATCHING OF HOLES IN FABRIC, METAL, OR COMPOSITE NON-

STRUCTURAL COMPONENT

2.1

Fabric Repairs

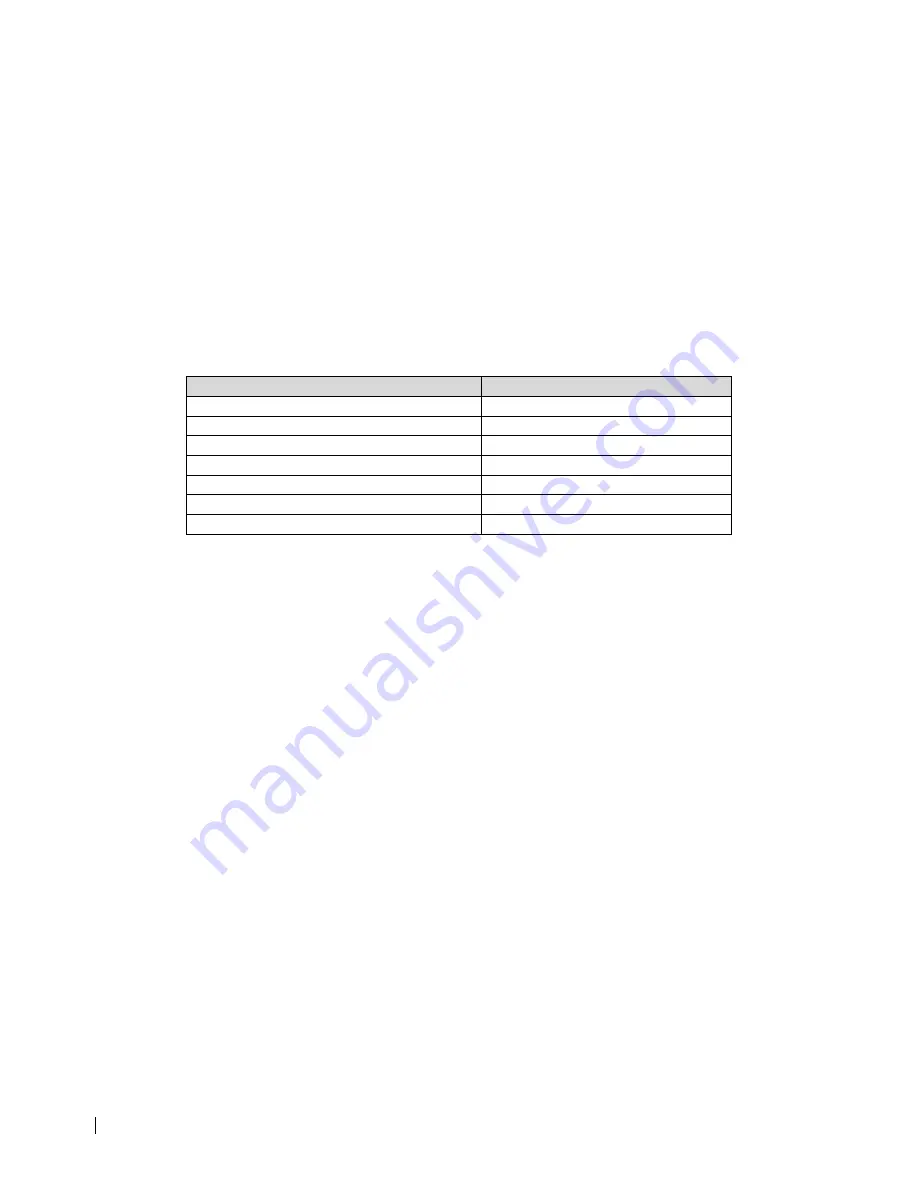

(1) APPROVED FABRIC REPAIR MATERIALS

Description

Supplier

Methyl Ethyl Ketone (MEK)

Local Supplier

Poly-Fiber

Poly-Fiber Aircraft Coating

Poly-Tak

Poly-Fiber Aircraft Coating

Poly-Brush

Poly-Fiber Aircraft Coating

Poly-Spray

Poly-Fiber Aircraft Coating

Flat Rib Lace Cord

Poly-Fiber Aircraft Coating

LOCTITE

Depend 330 Adhesive

Cub Crafters or Local Supplier

(2) INSPECTION OF FABRIC

The polyester fabric used is very durable and its longevity depends on maintaining the

coating in good shape. Ultraviolet radiation (in other words, direct sunlight) is the main

cause of deterioration of the fabric. The fabric is treated at the factory to protect it from

this type of radiation.

The fabric covering meets the requirements of TSO C-15d/AMS which stipulates that

the minimum breaking strength of the fabric should be at least 56 lbs. Testing fabric

requires skill and experience and should only be performed by a qualified person who

has experience in this matter.

The aircraft has been covered using a process that is proprietary to Cub Crafters. It is

similar to the Poly-Fiber Aircraft coating process, more commonly referred to as the Stits

method.

(3) FABRIC REPAIRS

The decision to repair damage on the fabric or whether to replace the covering on the

part will depend upon the extent of the damage and should take into account the

aesthetics of the repair. These repairs require the use of an iron to shrink the fabric. It is

very important that only a good quality clothing iron be used.

Summary of Contents for CARBON CUB SS CC11-160

Page 2: ...INTENTIONALLY LEFT BLANK...

Page 23: ...CHAPTER 5 AIRCRAFT MAINTENANCE MANUAL...

Page 24: ...INTENTIONALLY LEFT BLANK...

Page 115: ...CHAPTER 6 LINE MAINTENANCE REPAIRS AND ALTERATIONS...

Page 116: ...INTENTIONALLY LEFT BLANK...

Page 325: ...CHAPTER 7 HEAVY MAINTENANCE REPAIRS AND ALTERATIONS...

Page 326: ...INTENTIONALLY LEFT BLANK...

Page 331: ...CHAPTER 8 OVERHAUL...

Page 332: ...INTENTIONALLY LEFT BLANK...

Page 339: ...CHAPTER 9 MAJOR REPAIRS AND ALTERATIONS...

Page 340: ...INTENTIONALLY LEFT BLANK...

Page 345: ...CHAPTER 10 TASK SPECIFIC TRAINING...

Page 346: ...INTENTIONALLY LEFT BLANK...

Page 351: ...CHAPTER 11 SAFETY DIRECTIVES COMPLIANCE...

Page 352: ...INTENTIONALLY LEFT BLANK...