Calibration

Calibrating the Scale

CubiScan 125

45

Calibrating the Scale

To perform the calibration, you will need the following:

•

Official test weight up to 50 pounds (25 kg) (it is recommended that you

calibrate with the maximum weight)

IMPORTANT:

Do not begin scale calibration until you have the test

weight. Calibrating without an accurate known weight (within .01 of a

lb/kg) can make all future weight readings inaccurate.

Take the following steps to calibrate the CubiScan 125 scale.

N

OTE

When calibrating the scale, the CubiScan 125 must be stable with no movement of

the platform such as that caused by vibration or air movement.

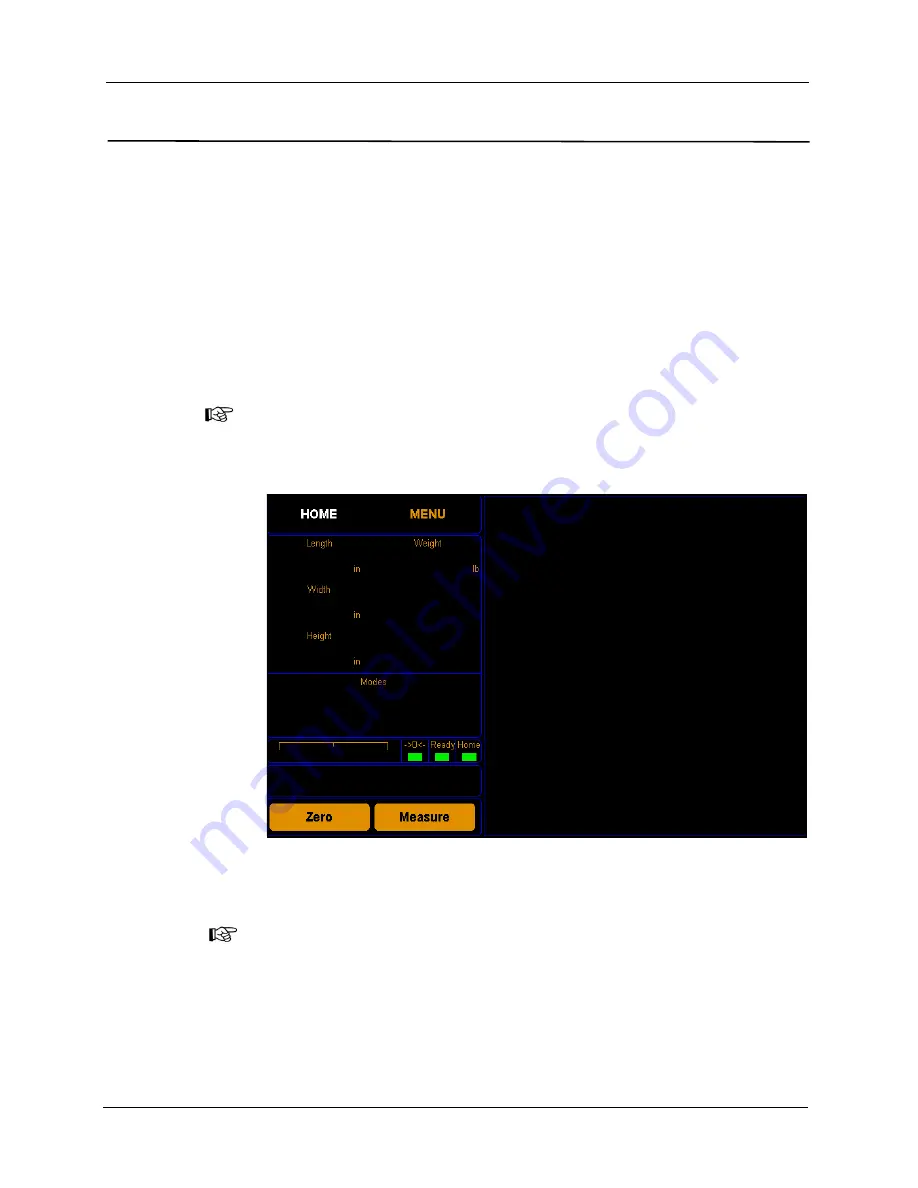

1. At the home screen, tap

MENU

.

N

OTE

If you have set up a password previously in the system configuration, you need to

enter the password to unlock the menu. Refer to

Figure 39

Home Screen