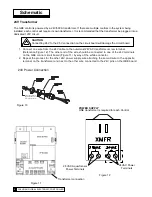

CAUTION

Connecting 24V to the 2.5v

connection on the circuit board

will damage the circuit board.

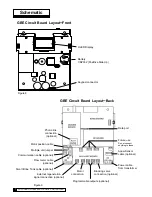

Outputs

The circuit board supports four outputs:

• Motor control (DC Motor)

• Blocking valve (Use Aux Out 4)

• Four programmable auxiliary outputs (Aux Out 1

through 4)

• Controller interface (communication between mul-

tiple controllers) (RS485).

Note:

If you are using Aqua-Sensor, you should run the 2.5v wiring now as the cable is run through the same cord grip.

See page 15 for details.

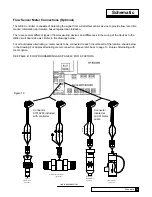

1. Locate the power cord among the controller parts. It has a white connector on one end and two spade connectors on the

other.

2. Locate the cord grip among the parts.

3. To assemble the power cord, first run the cord grip nut over the spade terminal end of the power cord.

4. Next, run the spade terminals through a hole in the side of the controller FROM THE INSIDE. See figure 10.

5. Finally, run the cable through the bottom end of the cord grip, and assemble the grip to the controller wall.

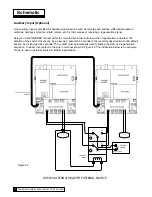

6. Plug the board connector to the board where it says “

24v

”. The connector has four (4) connections but only two wires are

connected. The other end of the power cord (with spade terminals) should be connected to the two

24VAC

terminals on

the transformer (see figure 12).

DO NOT PLUG THE TRANSFORMER INTO THE WALL UNTIL ALL WIRING IS COMPLETED.

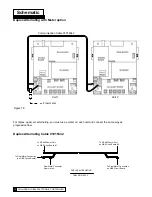

Repeat the process for any additional units in the system.

Schematic

8

7

CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Schematic

Summary of Contents for GBE

Page 62: ...Menu Overview Continued on page 61 59 CULLIGAN GLOBAL ELECTRONIC CONTROLLER ...

Page 63: ...Menu Overview Menu Overview 60 ...

Page 64: ...Menu Overview Continued from page 59 61 CULLIGAN GLOBAL ELECTRONIC CONTROLLER ...

Page 65: ...Menu Overview Menu Overview 62 ...

Page 72: ...Appendix D 69 CULLIGAN GLOBAL ELECTRONIC CONTROLLER ...