INSTALLATION AND OPERATION MANUAL

MF3700, MF3800 Models

Page 6

800-345-6007

CumberlandStoveWorks.com

OPERATING STOVE

Once the stove has been properly installed and plugged

into a grounded surge protector you are ready to begin

operation.

IMPORTANT:

Before filling the hopper make sure all

shipping and packaging items are removed from the

hopper and there are no obstructions in the auger housing

opening.

Fill the hopper with an approved solid fuel and close the

lid.

The first screen you will see upon power up is the model

and version of software loaded in the control. It will then

default to the Fuel Range Selection Mode.

FUEL RANGE SELECTION

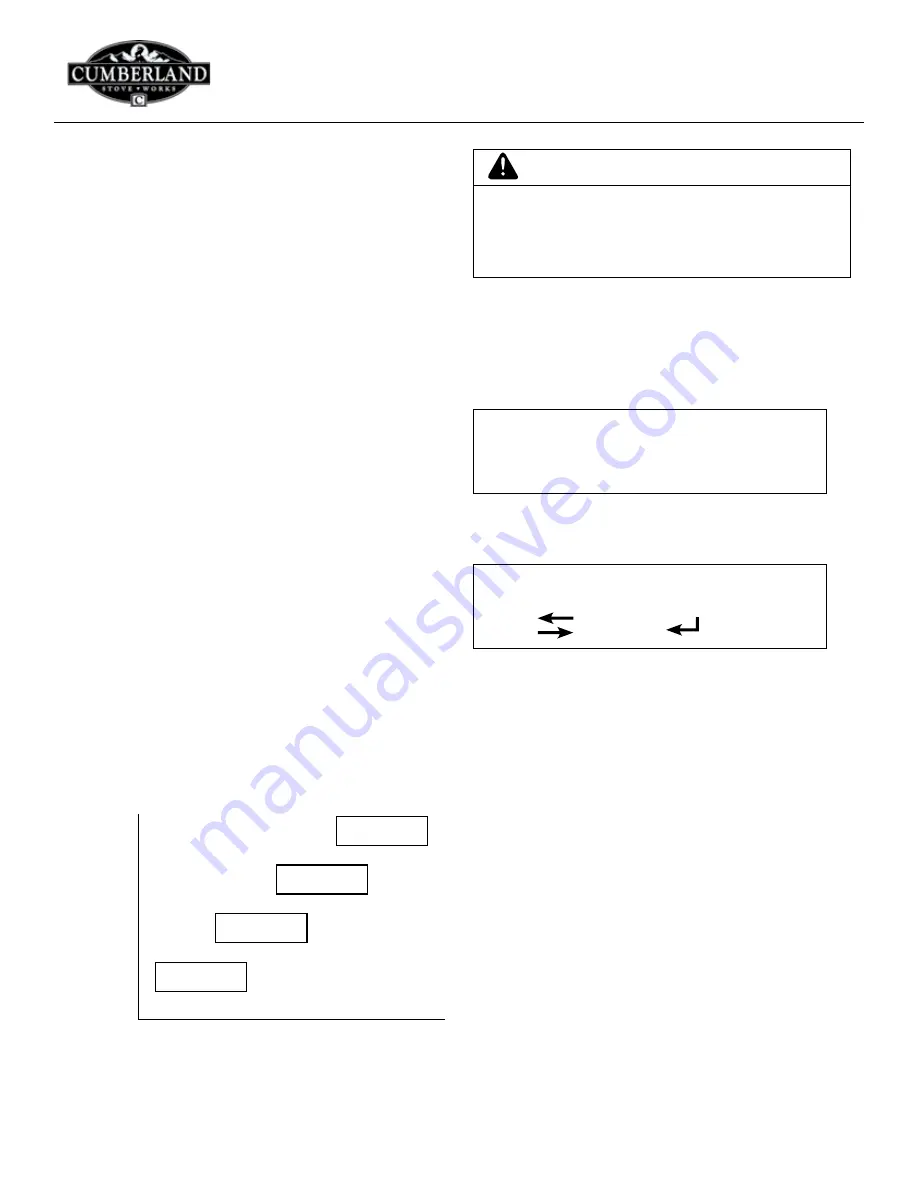

The CSW Multi Fuel Parlor stove has four fuel ranges

and six heat output Levels within each fuel range. This

gives the stove 24 levels of variability maximizing burn

with your chosen fuel. Range 1 Level 1 is the lowest feed

rate/combustion airflow and Range 4 Level 6 is the highest

feed rate/combustion airflow. See figure 23.

rangeS For aPProveD FueLS

• Corn 1-2

• Wood Pellets 2-3-4

• Cherry Pits 4

SeLeCting the range

The control will offer two selections on the screen. To

browse through the range selections use the SCROLL

button. To choose a range scroll through until the desired

Range is on top and press ENTER. Range may be changed

at anytime during stove operation by pressing the SCROLL

button.

Starting a Fire

After the Range has been loaded the controller will then

instruct you to light the fire. MF3700 stove controllers will

read as follows:

LIgHT FIRE

PUSH ON BUTTON

Stoves equipped with electric ignition (model MF3800) will

have the option of starting the fire manually or automatically

with the igniter. The screen will read as follows:

ELECTRIC IgNITE

no

yes

Pushing SCROLL will send the controller to the

LIGHT

FIRE PUSH ON BUTTON

. See Manual Lighting Instructions

before starting fire or pushing ON. For electric ignition read

ELECRTRIC IgNITION INSTRUCTIONS before pressing

ENTER.

manuaL Lighting inStruCtionS

IMPORTANT:

Before lighting the stove for the first time,

make sure that no shipping items have been left inside the

firebox or ash pan.

When initially filling an empty hopper you must prime the

feed auger. To prime the auger press the ADD FUEL button.

This will turn on your auger on for one minute or until the

ADD FUEL button is pressed again. Run feed auger until

you see fuel start to drop into the firepot.

Note:

The parlor stove has been designed with a safety

switch on the hopper lid. The auger will not run with the

hopper door open.

Fill the firepot with about one cup of starting pellets or

wood pellets. If wood pellets are used, squirt about two

tablespoons of burn gel on pellets.

Light the material in firepot using a match or a grill type

WARNING

NEVER PUT STARTING PELLETS OR BURN GEL INTO

THE HOPPER OF THE STOVE. THIS COULD RESULT

IN DEATH OR SERIOUS INJURY AND OR PROPERTY

DAMAGE. DOING SO WILL VOID ALL WARRANTIES.

Range 4

Range 3

Range 2

Range 1

Lowest Feed Rate/

Combustion Airflow

Highest Feed Rate/

Combustion Airflow

Levels 1-6

Levels 1-6

Levels 1-6

Levels 1-6

Figure 23: Feed rate chart.

Summary of Contents for MF3700

Page 2: ......